High-precision temperature monitoring circuit

A monitoring circuit and high-precision technology, applied in thermometers, thermometer parts, measuring devices, etc., can solve the problems of input signal influence and low monitoring accuracy, and achieve the effect of improving detection accuracy and reducing influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

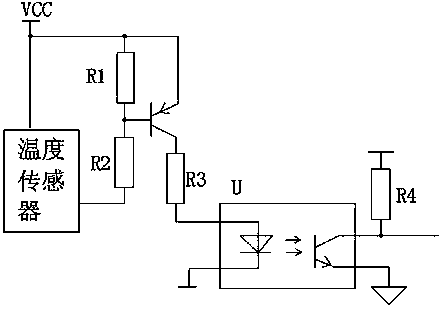

[0018] Such as figure 1 The high-precision temperature monitoring circuit shown includes a temperature sensor, a resistor R1, a resistor R2, a triode, a resistor R3, and an optocoupler U. After the resistor R1 is connected in series with the resistor R2, the non-common end of the resistor R2 is connected to the temperature sensor. , the non-common end of the resistor R1 is connected to the power supply, the common end of the resistor R1 and the resistor R2 is connected to the base of the triode; the emitter of the triode is connected to the power supply, and the collector is connected to the resistor R3, and the resistor R3 The other end is connected to the input end of the optocoupler U, the output end of the optocoupler U is connected to a pull-up resistor R4, and the temperature sensor is connected to the power supply at the same time. When the temperature sensor is used to monitor the temperature, there is a high common-mode voltage on the line, and an optocoupler is used...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com