Force and pressure measurement model of bridge

A force measurement and pressure measurement technology, which is applied in the direction of measuring devices, aerodynamic tests, and machine/structural component testing, can solve problems such as inaccurate force measurement, mutual interference of forces, and large errors in pressure integration methods, so as to avoid End effect, the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

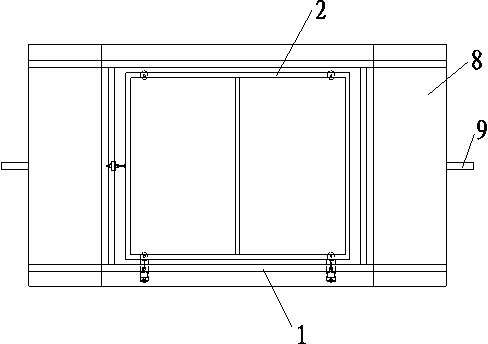

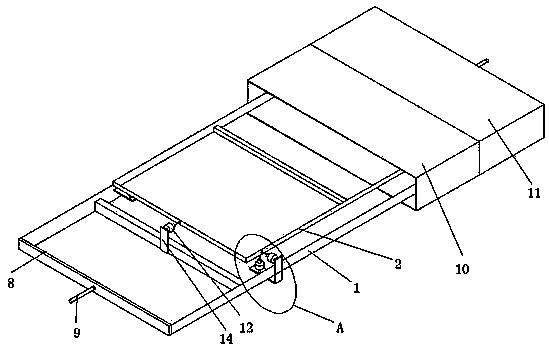

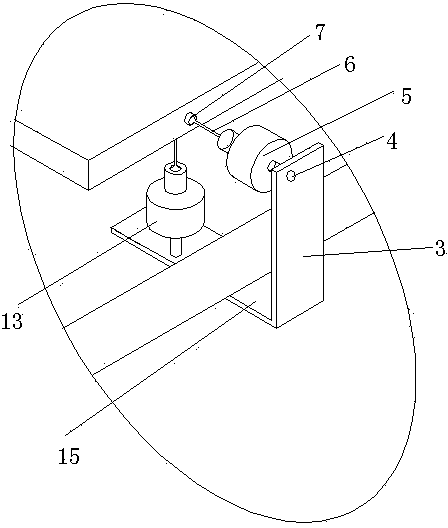

[0020] Such as figure 1 As shown, a bridge force measurement and pressure measurement model includes a rectangular suspension frame 2, a suspension frame coat 10 outside the suspension frame 2, a force measuring mechanism for measuring the force of the suspension frame 2, and a rectangular support set under the suspension frame 2. Frame 1, the length of the long side of the support frame 1 is greater than the length of the long side of the suspension frame 2, and the length of the wide side of the support frame 1 is greater than the length of the wide side of the suspension frame 2; The axial force sensor 12 with the central line of the wide side of the frame 2 on a straight line, a plurality of vertical force sensors 13 vertically arranged at the bottom of the suspension frame 2, and a plurality of vertical force sensors 13 arranged on one side of the suspension frame 2 and parallel to the direction of the width of the suspension frame 2 A plurality of lateral force sensor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com