Ultrasonic dual-probe manual detection method

A technology of manual detection and detection method, which is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids, etc., to achieve the effect of simple and easy operation, increase the detection angle range, and accurately measure the height of defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings. The features of the present invention will become clearer and more specific with these descriptions.

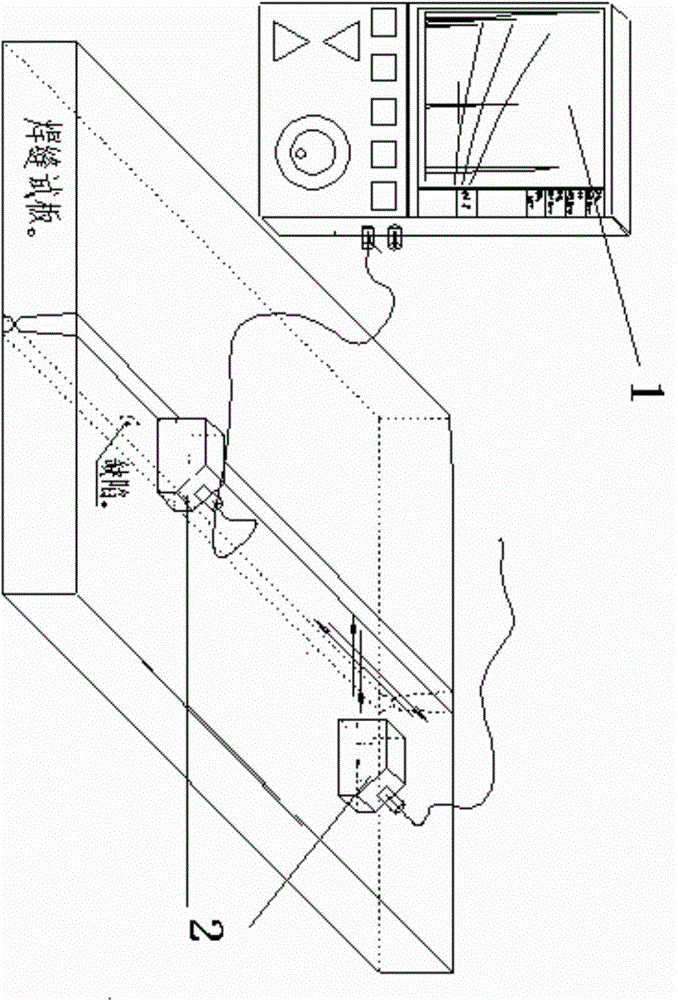

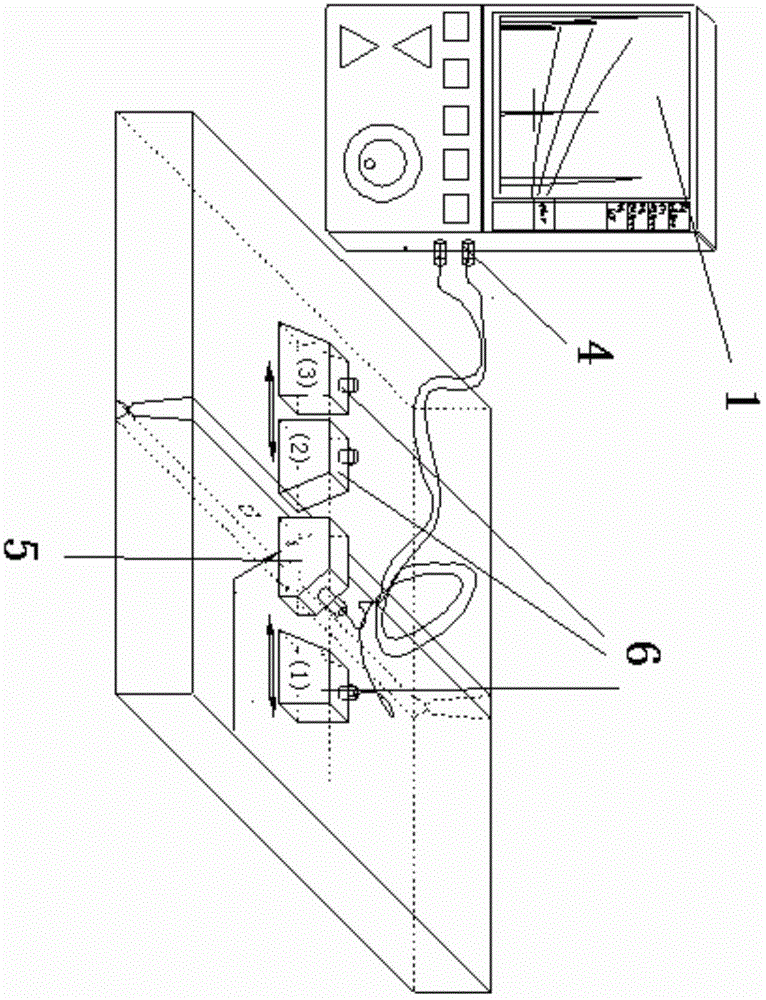

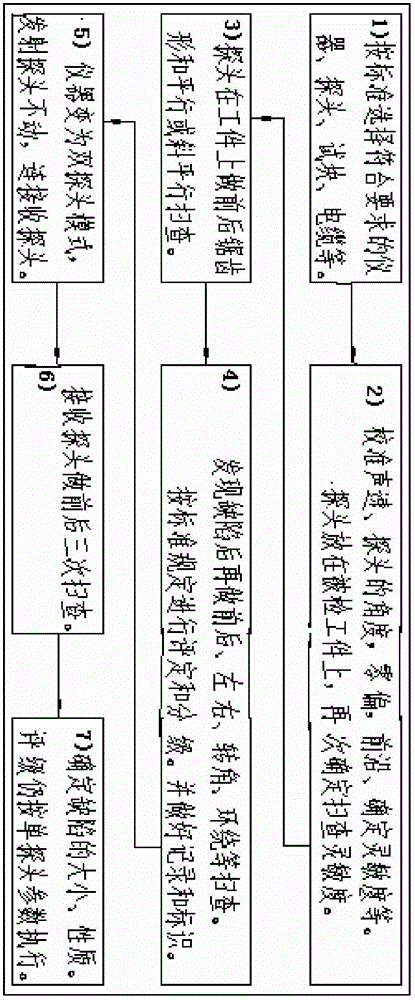

[0031] figure 1It is a schematic diagram of a conventional ultrasonic testing device. The detection method is: A-ultrasonic flaw detector 1, monoclinic probe 2, test block selected according to JB / T4730.3-2005 standard. Adjust the linearity of the instrument, set various instrument parameters, and determine the detection sensitivity to draw the DAC curve. Then increase the sensitivity by several decibels based on the set sensitivity. Do zigzag scans on the workpiece to be inspected, front and back, left and right; horizontal parallel (or oblique parallel) scans. When the internal defects of the workpiece are found, the defects are scanned in the form of front and back, left and right, corners, and surrounds. Based on the DAC curve, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viewing angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com