Mechanical pulse vibration exciter

A pulse-excited, mechanical technology, used in machine/structural component testing, vibration testing, fluids utilizing vibration, etc., and can solve problems such as uneven excitation force, long data acquisition time, and inability to collect structural frequencies. , to achieve the effect of uniform percussion force and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

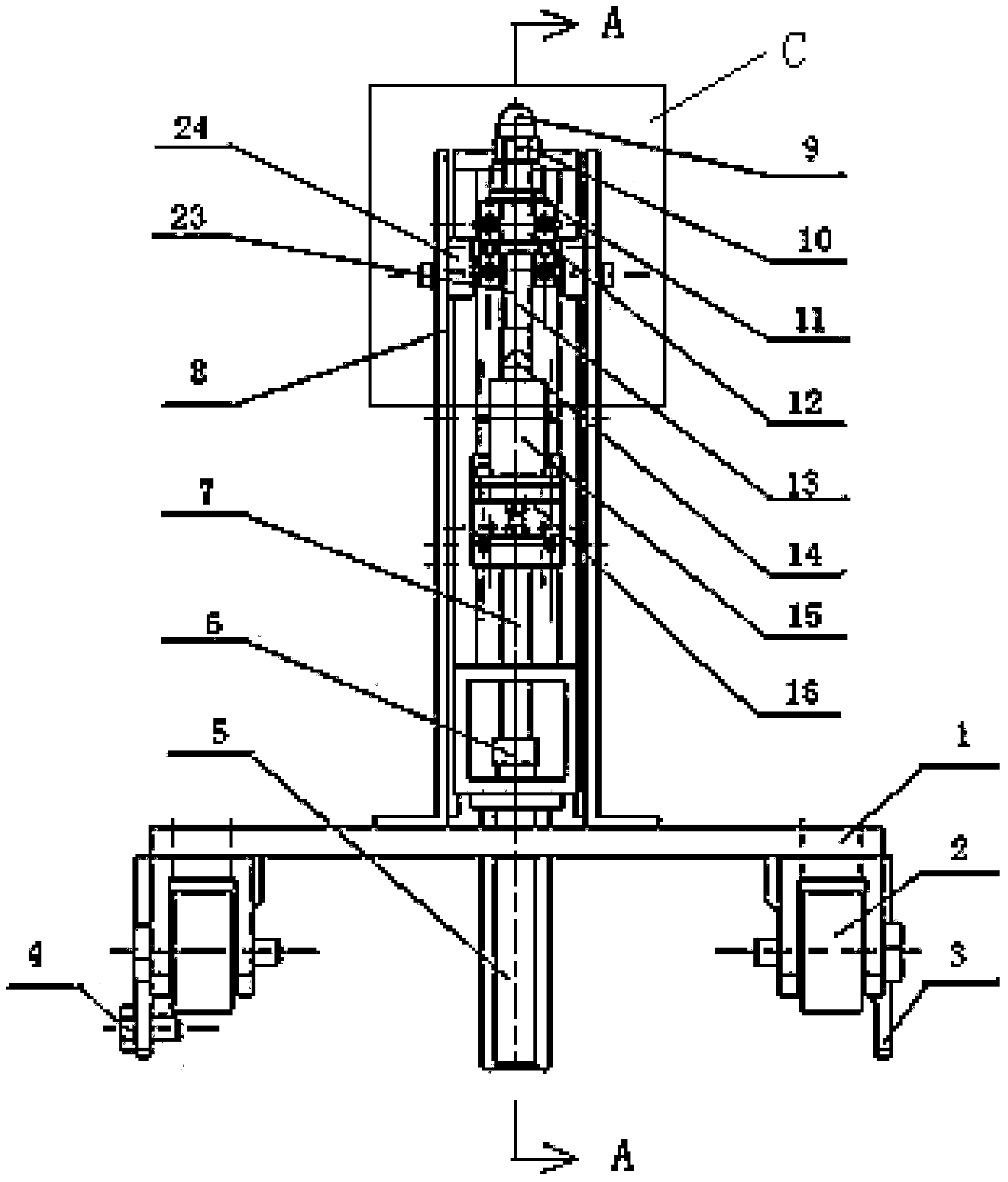

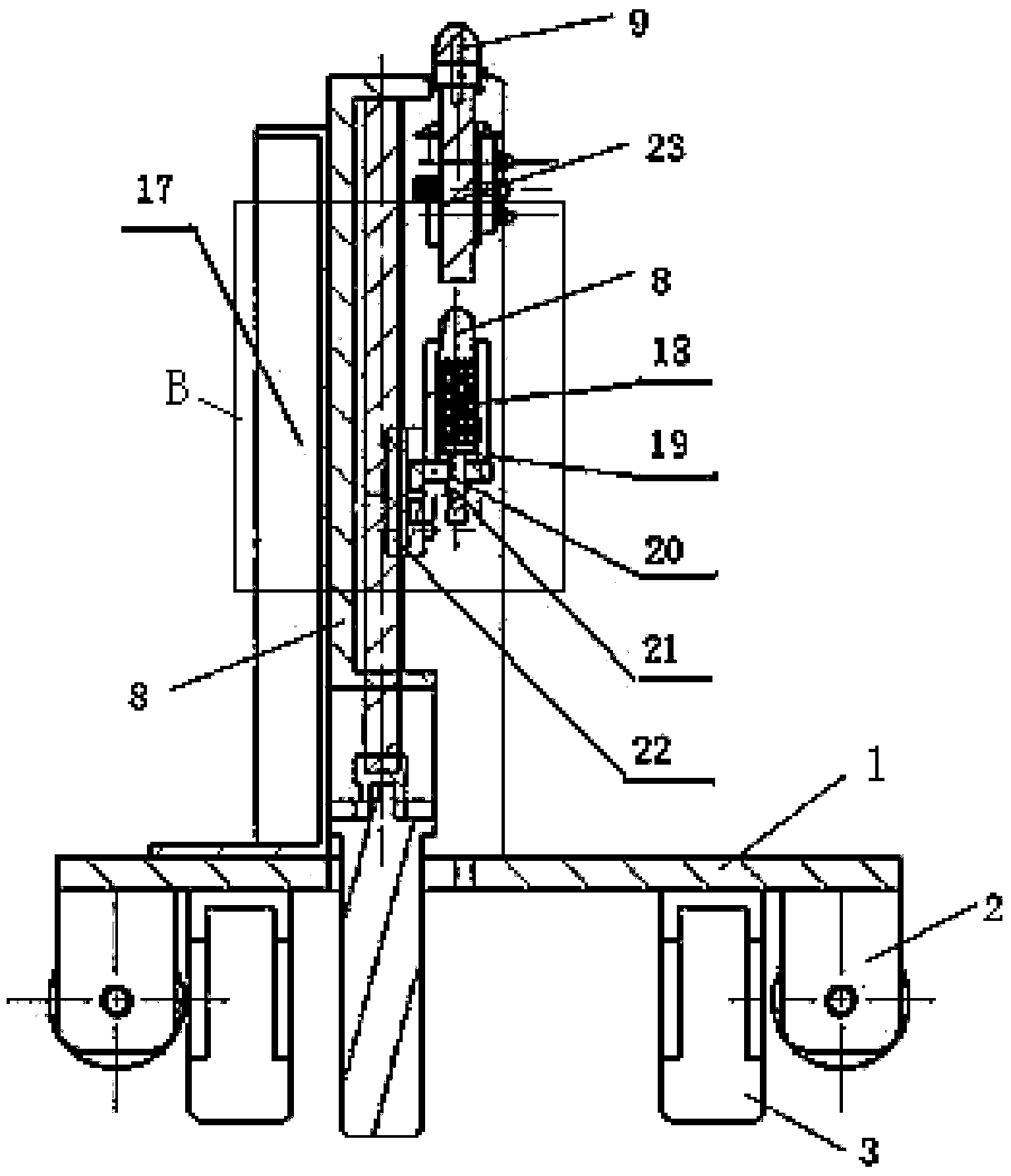

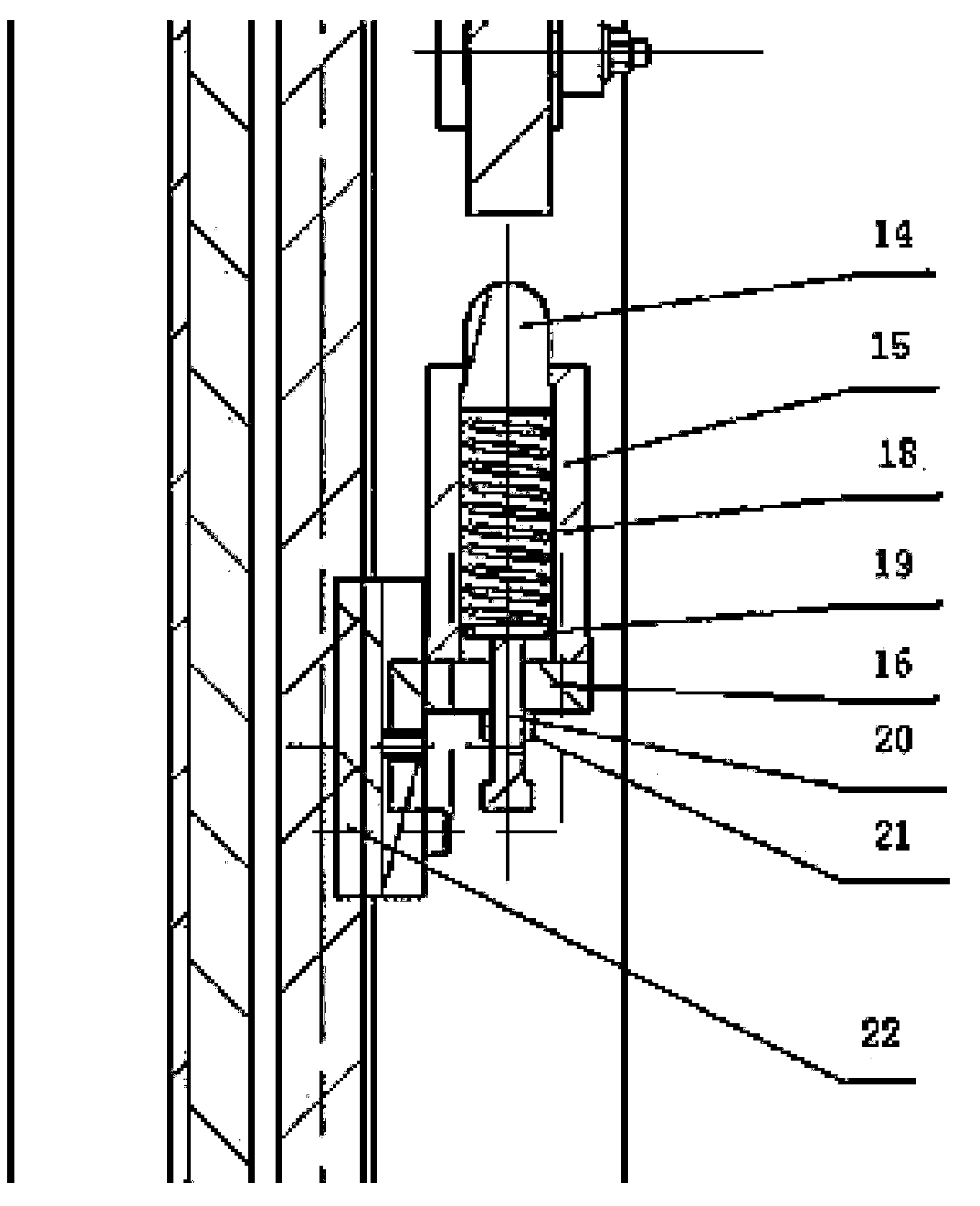

[0019] The present invention provides a kind of mechanical pulse exciter, its structure sees figure 1 and figure 2 , including a base plate 1 arranged horizontally, a ball screw 7 is vertically arranged above the base plate 1, a servo motor 5 is arranged below the base plate 1, the output shaft of the servo motor 5 passes through the base plate 1 and is connected with one end of the ball screw 7, and the ball screw A primary impact body is provided on the bar 7; two sliding impact rod brackets 8 are vertically provided above the bottom plate 1, and a secondary impact body is arranged between the two sliding impact rod brackets 8, and the secondary impact body is correspondingly arranged on the primary impact body. Above, the secondary impact body is connected with the sliding impact rod bracket 8 through the guide wheel mechanism; the rolle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com