Edgewise pouring device for foundation plate

A technology of base plate and pouring tube, applied in casting molding equipment, casting mold, core and other directions, can solve the problems of manpower and material resources, low production capacity, large quantity, etc., to save space, reduce production cost, improve The effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

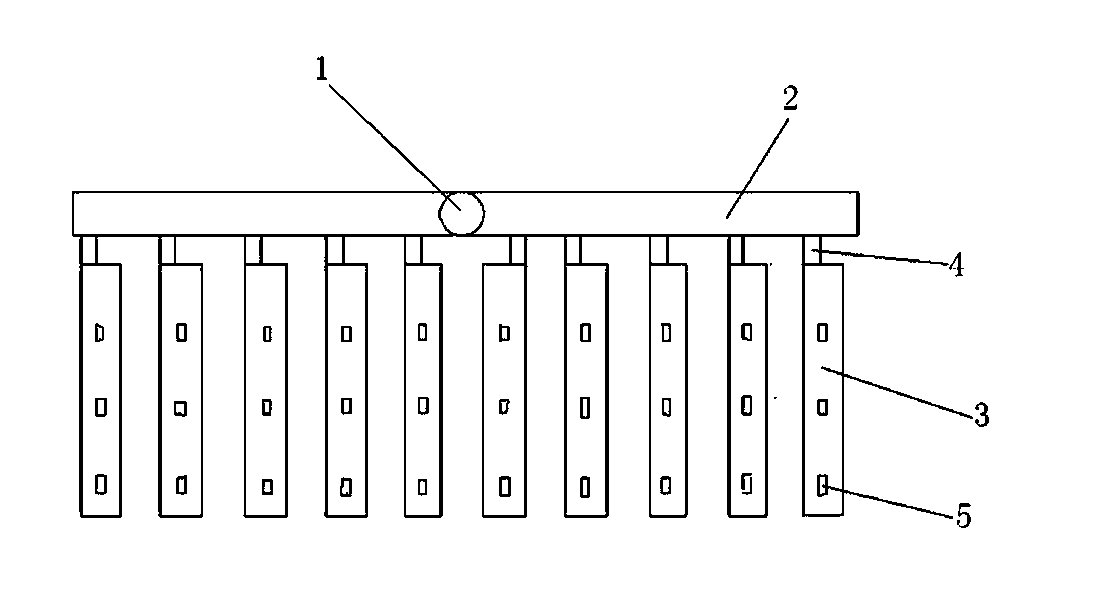

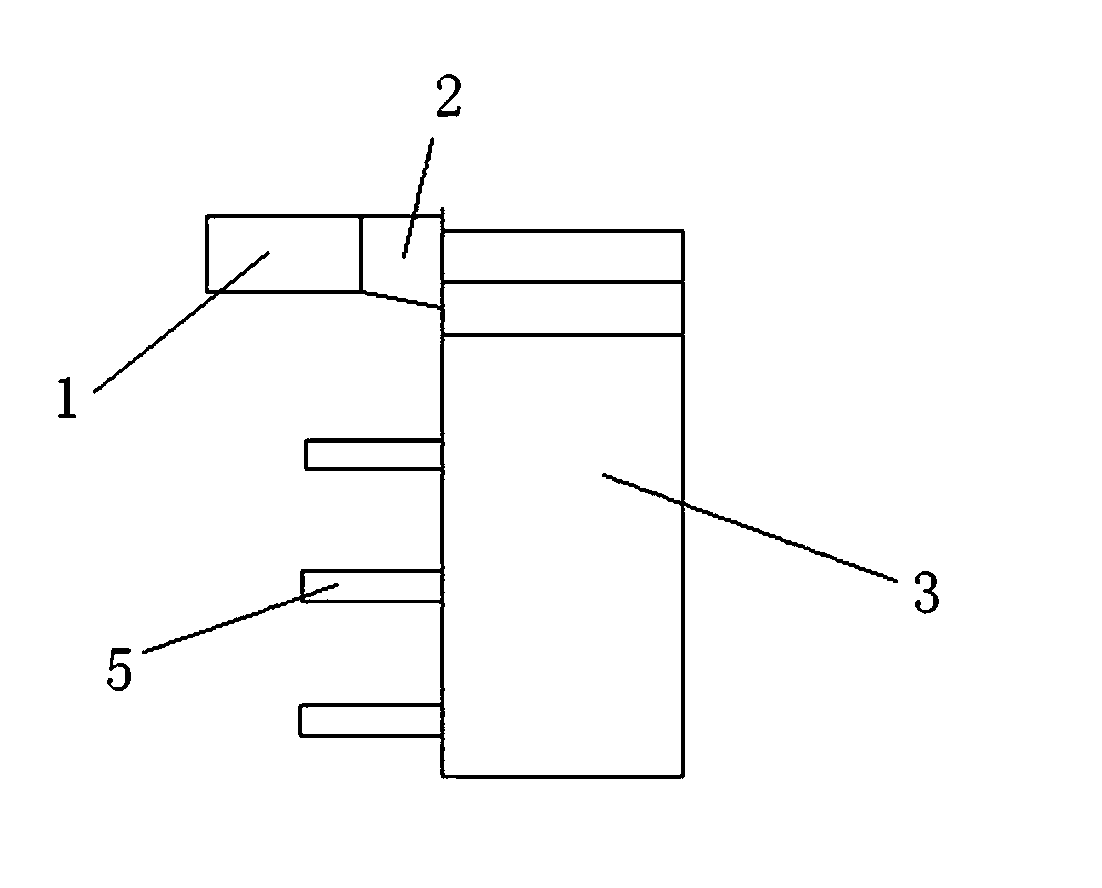

[0015] like figure 1 and figure 2 As shown, a foundation plate side pouring device includes a gate 1, a pouring pipe 2 and several foundation plate molds 3, based on the use direction, one end of the gate is fixedly connected to the pouring pipe, and the The above-mentioned several base plate molds are arranged at intervals along the axial direction of the pouring pipe, and the width direction of the base plate molds is in the vertical direction. In this way, the base plate molds are arranged at vertical intervals, and the position of the base plate molds is compact, which can greatly save the base plate. The mold occupies a lot of space, which can greatly improve the production efficiency of the foundation plate, and the foundation plate mold is set vertically, using the weight of the foundation plate casting itself combined with the sequential solidification characteristics, so that the foundation plate casting can naturally play a role in feeding during the pouring process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com