A shot blasting device with double splitting wheels and double directional sleeves

A technology of blasting wheel and directional sleeve, which is applied in the direction of grinding/polishing equipment, etc., can solve the problems of low efficiency and achieve the effect of high efficiency, fast shot blasting speed and uniform shot blasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

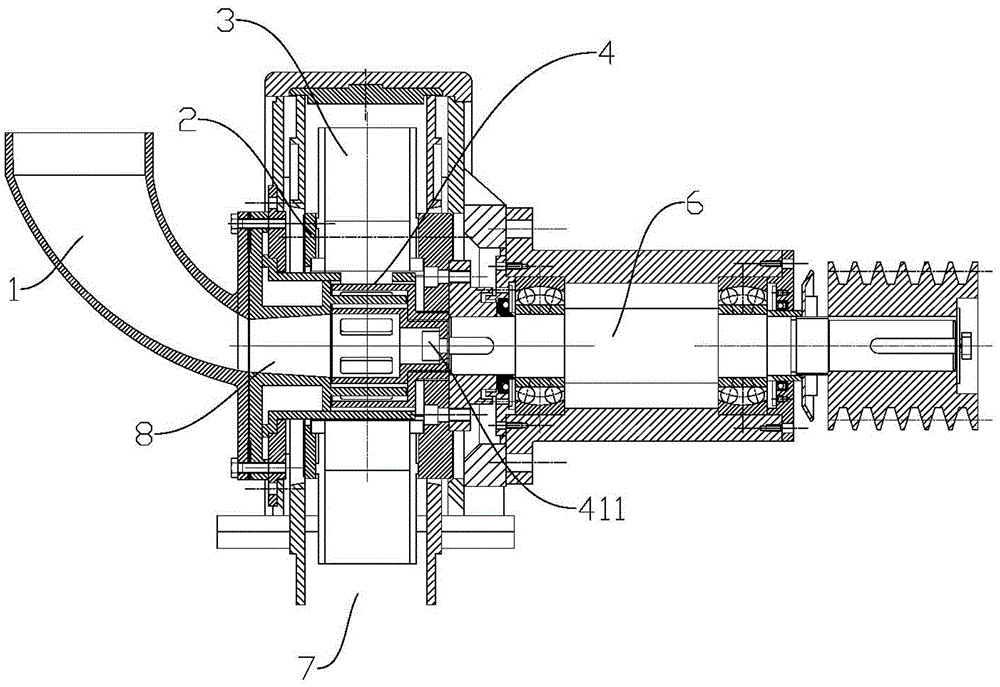

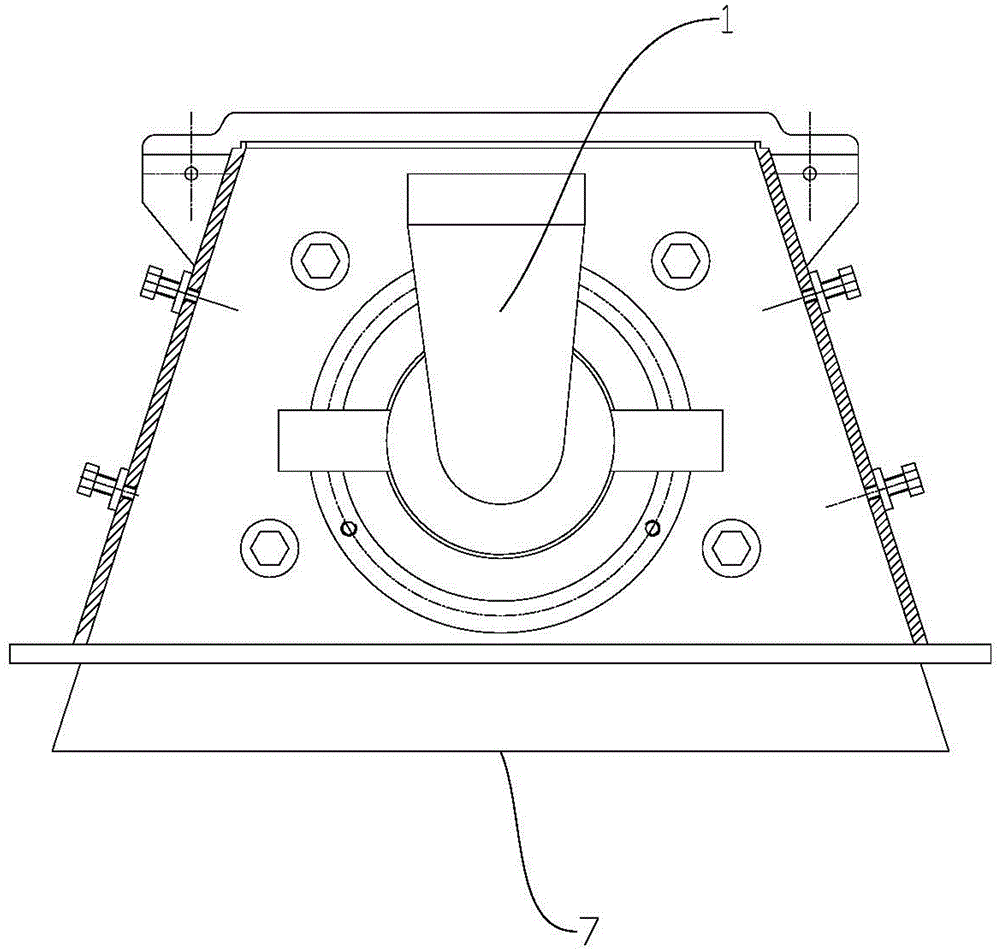

[0024] Such as Figure 1-4 As shown, the shot blaster with double shot wheel and double directional sleeve includes a main shaft 6, a casing, a shot feed tube 1, a double shot wheel and double directional sleeve assembly 4, an impeller body 2, and a blasting blade 3.

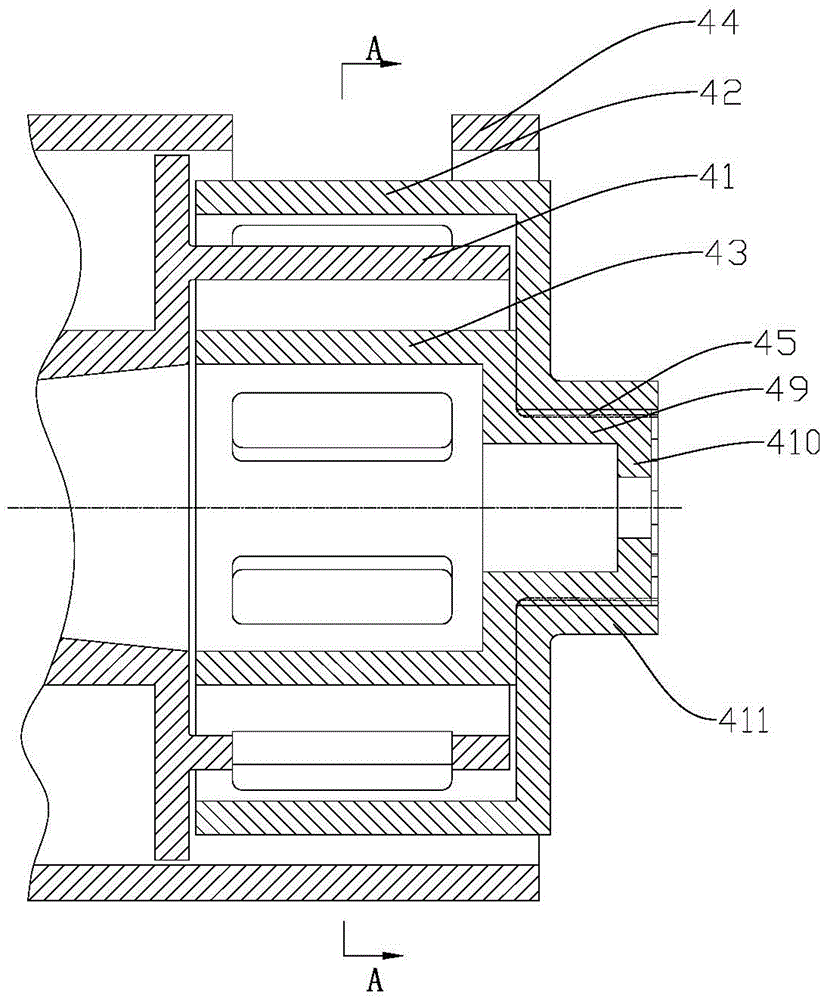

[0025] The double directional cover assembly 4 of described double shot wheel specifically refers to: the shot wheel is provided with two, one is the inner shot wheel 43, and the other is the outer shot wheel 42; the directional cover is also provided with two, and one is an internal fixed To sleeve 41, one is outer orientation sleeve 44.

[0026] The right end of described inner shot wheel 43 is coaxially fixed with inner connecting cylinder 49, and the right end of inner connecting cylinder 49 is provided with sealing plate 410, and this sealing plate 410 is fixed with described main shaft 6 by hexagon socket bolt 411; The right end of the shot wheel 42 is also coaxially fixed with an outer connecting cylinde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com