Light guide plate mould

A light guide plate and mold technology, which is applied in the field of light guide plate molds, can solve problems such as product quality degradation, mold surface damage, and broken molds, and achieve the effects of smooth flow, improved service life, and elimination of air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

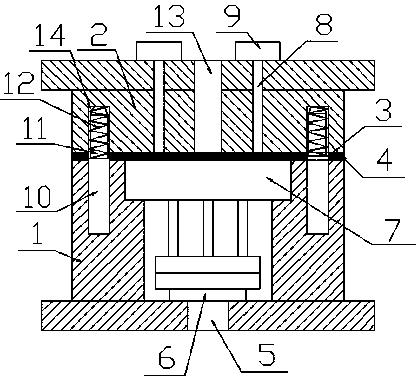

[0016] see figure 1 As shown, a light guide plate mold of the present invention includes a lower mold 1, an upper mold 2 arranged above the lower mold 1, a ejector pin hole 5 arranged at the bottom of the lower mold 1, and a sealing seal arranged at the position of the ejector pin hole 5. Bar 6, and the mold cavity 7 that is arranged in the lower mold 1, and the injection hole 13 that is arranged on the upper mold 2, and the exhaust hole 8 that is arranged in the upper mold 2 and communicates with the mold cavity 7, and is arranged in the row The vacuum exhauster 9 at the top of the air hole 8, the upper mold 2 and the lower mold 1 cooperate to form a parting surface 3, the parting surface 3 is provided with a sealing ring 4, and the upper mold 2 and the lower mold 1 A guide post is also arranged between, and a damping spring 12 is arranged on the guide post.

[0017] Wherein, the guide post is divided into a main body part 10 and a guide part 11, the damping spring 12 is arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com