Production method of tempered high-strength Q800D super-thick steel plate

A technology of extra-thick steel plate and production method, which is applied in the field of iron and steel smelting, can solve the problems of low pass rate of steel plate ultrasonic flaw detection, steel plate cannot be used as structural parts, etc., and achieve the effect of easy process, simple process and reduced production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

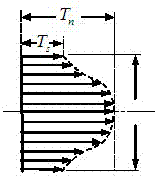

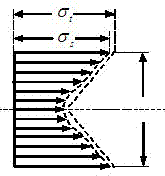

Image

Examples

Embodiment 1

[0039] Example 1: Refining and tempering high-strength Q800D extra-thick steel plates with a plate thickness of 100 mm.

[0040] The mass percentage of chemical composition of steel is: C=0.14, Si=0.28, Mn=1.26, P=0.010, S=0.001, Als=0.042, Nb=0.032, V=0.047, Ti=0.014, Ni=0.42, Cr= 0.46, Mo=0.50, B=0.0018, the balance is Fe and unavoidable impurities; CEV=0.58.

[0041] The production process steps and parameters of steel are:

[0042] (1) Continuous casting: Produce 300X2280mm cross-section continuous casting slabs according to the clean steel production method, in which the superheat of the continuous casting tundish is less than 10°C, the light reduction is 4mm, and the electromagnetic stirring current is controlled by 300A (7Hz).

[0043] (2) Heating: The slab is heated at 1290-1300°C, the heating time is 11min / cm, the soaking time is 64min, the temperature of the upper surface is 15°C higher than that of the lower surface, and the temperature of the core of the slab out ...

Embodiment 2

[0051] Example 2: Refining and tempering high-strength Q800D extra-thick steel plates with a plate thickness of 120 mm.

[0052] The chemical composition mass percentage of steel is:

[0053] C=0.14, Si=0.28, Mn=1.19, P=0.011, S=0.001, Als=0.039, Nb=0.029, V=0.047, Ti=0.018, Ni=0.53, Cr=0.46, Mo=0.52, B= 0.0018, the balance is Fe and unavoidable impurities; CEV=0.58.

[0054] The production process steps and parameters of steel are:

[0055] (1) Continuous casting: Produce 300X2280mm cross-section continuous casting slabs according to the clean steel production method, in which the superheat of the continuous casting tundish is less than 10°C, the light reduction is 4mm, and the electromagnetic stirring current is controlled by 300A (7Hz).

[0056] (2) Heating: The slab is heated at 1290-1300°C, the heating time is 13min / cm, the soaking time is 71min, the temperature of the upper surface is 18°C higher than that of the lower surface, and the temperature of the core of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com