Patents

Literature

36results about How to "Improve the qualified rate of ultrasonic flaw detection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of quenched and tempered high-intensity Q890D super-thick steel plate

ActiveCN103589969AMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingSteel plates

A production method of a quenched and tempered high-intensity Q890D super-thick steel plate comprises processing steps as follows: liquid iron pretreatment, converter steelmaking, secondary refining, continuous casting including dynamic soft reduction and electromagnetic stirring, heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance examination and ultrasonic flaw detection. Steel comprises chemical composition in percentage as follows: not more than 0.16% of C, 0.20%-0.40% of Si, 1.30%-1.40% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03%-0.05% of Als, not more than 0.10% of Nb+V+Ti, not more than 1.0% of Cu+Ni, 0.35%-0.45% of Cr, 0.45%-0.70% of Mo, not more than 0.0025% of B and the balance of Fe and unavoidable impurities. The produced high-performance quenched and tempered high-intensity Q890D super-thick steel plate with a thickness ranging from 100 mm to 120 mm can meet the manufacturing requirement of heavy machinery for a mine, a port and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q690D super-thick steel plate

ActiveCN103556077AMeet the needs of heavy machinery manufacturingMeet the requirements of mechanical manufacturingQuenchingImpurity

The invention relates to a production method of a quenched and tempered high-strength Q690D super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.00-1.30% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.10% of Nb+V+Ti, not more than 1.0% of Cu+Ni, 0.40-0.70% of Cr, 0.50-0.70% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q690D super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

H13 round steel continuous casting and continuous rolling manufacturing process

ActiveCN109158558AAvoid crackingAvoid surface crackingWork heating devicesMetal rolling arrangementsHot workingContinuous rolling

The invention relates to a continuous casting and continuous rolling manufacturing process of H13 round steel for hot working molds with specifications of phi 50 mm to phi 150 mm; the alloy content ofthe steel is 9%; arc billet continuous casting machines with sections above 300*400 mm are used for continuous casting; and a 850 reversible and continuous casting unit is used for rolling. As the alloy content of the steel is higher, the bad segregation, middle cracks and center cracks are easily generated in the solidification process, the deformation resistance in the continuous casting process is high, the surface rolling defects are easily generated, the welding is difficult in the rolling process due to internal looseness, the cracking phenomenon is easily generated through air coolingafter rolling, and the quality of rolled materials and final products is badly influenced. A continuous casting electromagnetic stirring technology, a light pressing technology and an ultraweak cold technology are applied, and such processes as high-temperature dispersion and belt temperature annealing are combined to effectively control the grade of belt structures, to prevent center cracks and surface cracks of continuous-cast blanks and cooling stress cracks of the rolled materials and to improve the ultrasonic flaw detection pass percent of the rolled materials and the pass percentage of the belt structures.

Owner:NANJING IRON & STEEL CO LTD

Production method of tempered high-strength Q620D super-thick steel plate

ActiveCN103540865AMeet the needs of heavy machinery manufacturingMeet the requirements of mechanical manufacturingSteelmakingHigh intensity

The invention provides a production method of a tempered high-strength Q620D super-thick steel plate. The production method comprises the processing steps of molten steel pre-treatment, converter steelmaking, external refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, off-line quenching, tempering, finishing, performance examination and ultrasonic flaw detection, and is characterized in that steel comprises the following chemical components: not more than 0.16% of C, 0.20-0.40% of Si, 1.40-1.60% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.06 of Nb and Ti, not more than 1.0% of Cu and Ni, 0.30-0.60% of Cr, 0.30-0.50% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities; CEV (carbon equivalent) is controlled to be not more than 0.60 and is computed according to the formula C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm tempered high-strength Q620D super-thick steel plate meets the requirements for manufacturing heavy machinery for mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q890E super-thick steel plate

ActiveCN103555911AMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingImpurity

The invention relates to a production method of a quenched and tempered high-strength Q890E super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.30-1.40% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.05% of Als, not more than 0.10% of Nb+V+Ti, not more than 1.0% of Cu+Ni, 0.30-0.50% of Cr, 0.45-0.70% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q890E super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of hardened and tempered high-strength Q500E super-thick steel plate

ActiveCN103556074BMeet the requirements of mechanical manufacturingReduce manufacturing costSteelmakingQuenching

The invention discloses a production process of a hardened and tempered high-strength Q500E super-thick steel plate. The production method comprises process steps of molten iron pre-treating, converter steelmaking, external refining, continuous casting (dynamic soft pressing and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance examining and ultrasonic-wave flaw detecting. The steel comprises the chemical components in percentage by mass: not greater than 0.15% of C, 0.20%-0.40% of Si, 1.00%-1.30% of Mn, not greater than 0.015% of P, not greater than 0.003% of S, 0.03%-0.06% of AlT, not greater than 0.10% of Nb+Ti+V, not greater than 1.0% of Cu+Ni, 0.40%-0.70% of Cr, 0.30%-0.60% of Mo, not greater than 0.0025% of B, and the balance of Fe and inevitable impurities. CEV is controlled to be not greater than 0.58, and the CEV is calculated according to a formula of CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance hardened and tempered high-strength Q500E super-thick steel plate which is 100mm-120mm thick satisfies needs of manufacturing heavy machinery of a mine, a port, and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q550F super-thick steel plate

ActiveCN103555910AMeet the needs of heavy machinery manufacturingMeet the requirements of mechanical manufacturingHigh intensityQuenching

The invention relates to a production method of a quenched and tempered high-strength Q550F super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.45-1.60% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.05% of Nb+Ti, not more than 1.0% of Ni, 0.30-0.50% of Cr, 0.30-0.50% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q550F super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q500D super-thick steel plate

ActiveCN103556075BMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingImpurity

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q620E super-thick steel plate

ActiveCN103555908AMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingImpurity

The invention relates to a production method of a quenched and tempered high-strength Q620E super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.40-1.60% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.06% of Nb+Ti, not more than 1.0% of Cu+Ni, 0.30-0.60% of Cr, 0.30-0.50% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q620E super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q690E super-thick steel plate

ActiveCN103556061AMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingImpurity

The invention relates to a production method of a quenched and tempered high-strength Q690E super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.14% of C, 0.20-0.40% of Si, 1.00-1.20% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.05% of Als, not more than 0.10% of Nb+V+Ti, not more than 1.0% of Cu+Ni, 0.40-0.60% of Cr, 0.45-0.70% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.57, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q690E super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q500D super-thick steel plate

ActiveCN103556075AMeet the requirements of mechanical manufacturingReduce manufacturing costHigh intensityQuenching

The invention relates to a production method of a quenched and tempered high-strength Q500D super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.15% of C, 0.20-0.40% of Si, 1.00-1.30% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of AlT, not more than 0.10% of Nb+Ti+V, not more than 1.0% of Cu+Ni, 0.40-0.70% of Cr, 0.30-0.60% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.58, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q500D super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q550D super-thick steel plate

ActiveCN103556078AMeet the needs of heavy machinery manufacturingMeet the requirements of mechanical manufacturingQuenchingImpurity

The invention relates to a production method of a quenched and tempered high-strength Q550D super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.00-1.30% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of AlT, not more than 0.10% of Nb+Ti+V, not more than 1.0% of Cu+Ni, 0.40-0.70% of Cr, 0.40-0.60% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q550D super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q500F super-thick steel plate

ActiveCN103555909AMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingImpurity

The invention relates to a production method of a quenched and tempered high-strength Q500F super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.15% of C, 0.20-0.40% of Si, 1.00-1.30% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of AlT, not more than 0.10% of Nb+Ti+V, not more than 1.0% of Cu+Ni, 0.40-0.70% of Cr, 0.30-0.60% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.58, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q500F super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of hardened and tempered high-strength Q500E super-thick steel plate

ActiveCN103556074AMeet the needs of heavy machinery manufacturingMeet the requirements of mechanical manufacturingSteelmakingHigh intensity

The invention discloses a production process of a hardened and tempered high-strength Q500E super-thick steel plate. The production method comprises process steps of molten iron pre-treating, converter steelmaking, external refining, continuous casting (dynamic soft pressing and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance examining and ultrasonic-wave flaw detecting. The steel comprises the chemical components in percentage by mass: not greater than 0.15% of C, 0.20%-0.40% of Si, 1.00%-1.30% of Mn, not greater than 0.015% of P, not greater than 0.003% of S, 0.03%-0.06% of AlT, not greater than 0.10% of Nb+Ti+V, not greater than 1.0% of Cu+Ni, 0.40%-0.70% of Cr, 0.30%-0.60% of Mo, not greater than 0.0025% of B, and the balance of Fe and inevitable impurities. CEV is controlled to be not greater than 0.58, and the CEV is calculated according to a formula of CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance hardened and tempered high-strength Q500E super-thick steel plate which is 100mm-120mm thick satisfies needs of manufacturing heavy machinery of a mine, a port, and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

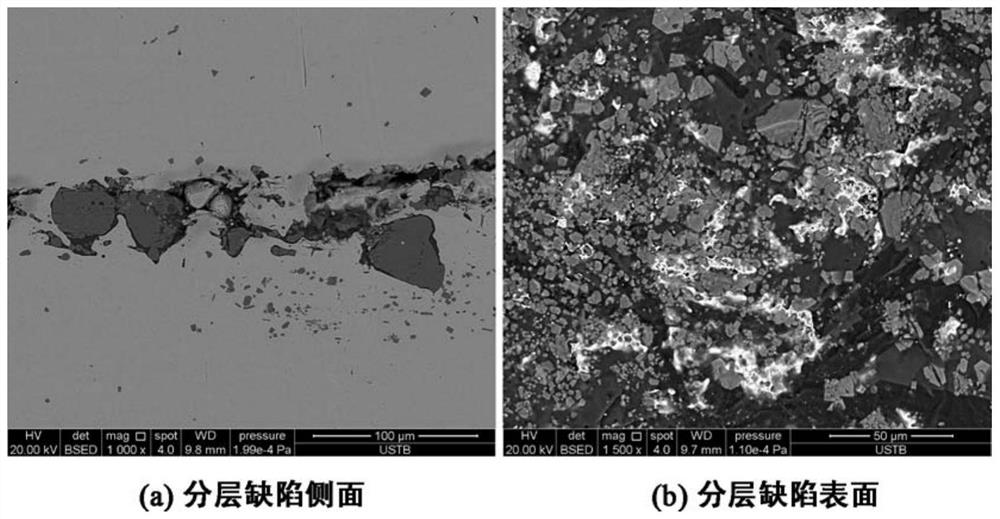

Smelting process for reducing layering defect of TP321 stainless steel seamless tube

ActiveCN113699429AReduce peroxidationReduce oxygen contentProcess efficiency improvementElectric arc furnaceCalcium handling

The invention relates to the technical field of stainless steel smelting, and provides a smelting process for reducing a layering defect of a TP321 stainless steel seamless tube. The smelting process comprises the following steps of providing crude molten steel by an electric arc furnace, carrying out AOD oxygen blowing decarburization, carrying out AOD ferrosilicon reduction, carrying out AOD aluminum deep deoxidation, tapping after AOD titanium alloying, carrying out soft stirring and calcium treatment in a steel ladle, and carrying out die casting. According to the smelting process, a process route of an electric arc furnace, a 20t AOD refining furnace, ladle treatment and the die casting is adopted, the Al element content in molten steel is strictly controlled before Ti alloying in the AOD refining furnace for deep deoxidation, after AOD tapping, silicon-calcium wires are fed into the steel ladle, high-melting-point Al2O3-MgO-TiOx inclusions in the molten steel are modified into low-melting-point inclusions, and the content of large-size SiO2-Al2O3-MnO-CaO and TiOx-MnO inclusions in the stainless steel is effectively reduced, the layering defect in the stainless steel seamless tube is reduced, and the ultrasonic flaw detection qualification rate of the stainless steel seamless tube is improved.

Owner:UNIV OF SCI & TECH BEIJING +1

Method for preparing high-precision small-caliber TA2 pipe for spaceflight

ActiveCN111496008ASmall and uniform tissueImprove performanceFurnace typesHeat treatment furnacesPipeSpaceflight

The invention provides a method for preparing a high-precision small-caliber TA2 pipe for spaceflight. The method for preparing the high-precision small-caliber TA2 pipe for the spaceflight comprisesthe following steps that 1, blanking and sawing, peeling and drilling are conducted on a TA2 bar to obtain a hollow pipe blank; 2, hot extrusion is performed on the hollow pipe blank; 3, surface treatment is performed on the pipe blank subjected to the hot extrusion; 4, annealing treatment is performed on the pipe blank subjected to the surface treatment; 5, the annealed pipe blank is subjected tomulti-roller cold rolling till the TA2 pipe with the final required size is obtained through the rolling; 6, finished product annealing treatment is conducted on the TA2 pipe which completes the coldrolling; and 7, straightening and head cutting are conducted on the TA2 pipe subjected to the finished product annealing, and a high-precision small-caliber TA2 pipe finished product is obtained after finishing. The high-precision small-caliber TA2 pipe prepared through the method has good comprehensive performance, the ultrasonic flaw detection qualification rate of the pipe is high, the inner and outer surface are smooth and free of defects, and the using requirement of the liquid rocket engine TA2 pipe can be met.

Owner:西安诺博尔稀贵金属材料股份有限公司

Production method of quenched and tempered high-strength Q620F super-thick steel plate

ActiveCN103556082AMeet the requirements of mechanical manufacturingReduce manufacturing costHigh intensityQuenching

The invention relates to a production method of a quenched and tempered high-strength Q620F super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.40-1.60% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.06% of Nb+Ti, not more than 1.0% of Cu+Ni, 0.30-0.60% of Cr, 0.30-0.50% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q620F super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of tempered high-intensity Q890D super-thick steel plate

ActiveCN103589969BMeet the requirements of mechanical manufacturingReduce manufacturing costSteelmakingChemical composition

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q800E super-thick steel plate

ActiveCN103556060AMeet the requirements of mechanical manufacturingReduce manufacturing costHigh intensityQuenching

The invention relates to a production method of a quenched and tempered high-strength Q800E super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.10-1.30% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.10% of Nb+V+Ti, not more than 1.0% of Cu+Ni, 0.40-0.75% of Cr, 0.50-0.75% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q800E super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of tempered high-strength Q800D super-thick steel plate

ActiveCN103540866AMeet the requirements of mechanical manufacturingReduce manufacturing costIncreasing energy efficiencySteelmakingHigh intensity

The invention provides a production method of a tempered high-strength Q800D super-thick steel plate. The production method comprises the processing steps of molten steel pre-treatment, converter steelmaking, external refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, off-line quenching, tempering, finishing, performance examination and ultrasonic flaw detection, and is characterized in that steel comprises the following chemical components: not more than 0.16% of C, 0.20-0.40% of Si, 1.10-1.30% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.10 of Nb, V and Ti, not more than 1.0% of Cu and Ni, 0.40-0.75% of Cr, 0.50-0.75% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities; CEV (carbon equivalent) is controlled to be not more than 0.60 and is computed according to the formula C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm tempered high-strength Q800D super-thick steel plate meets the requirements for manufacturing heavy machinery for mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

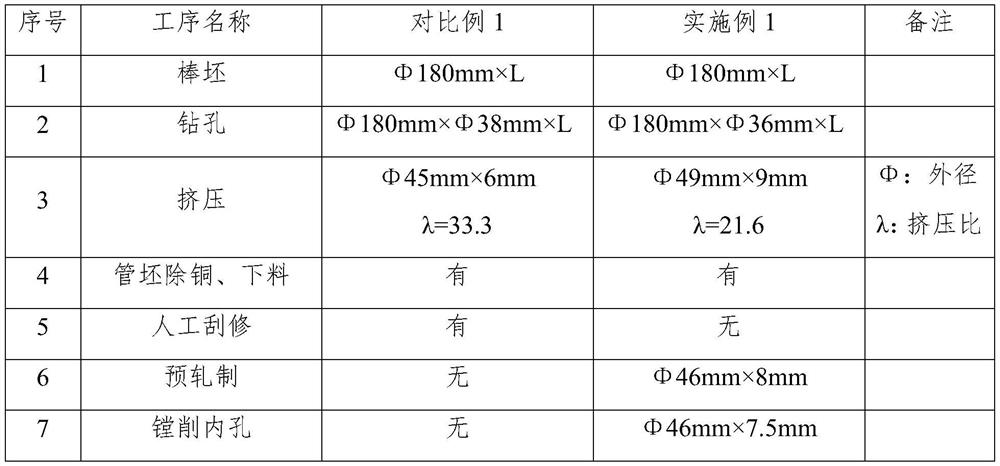

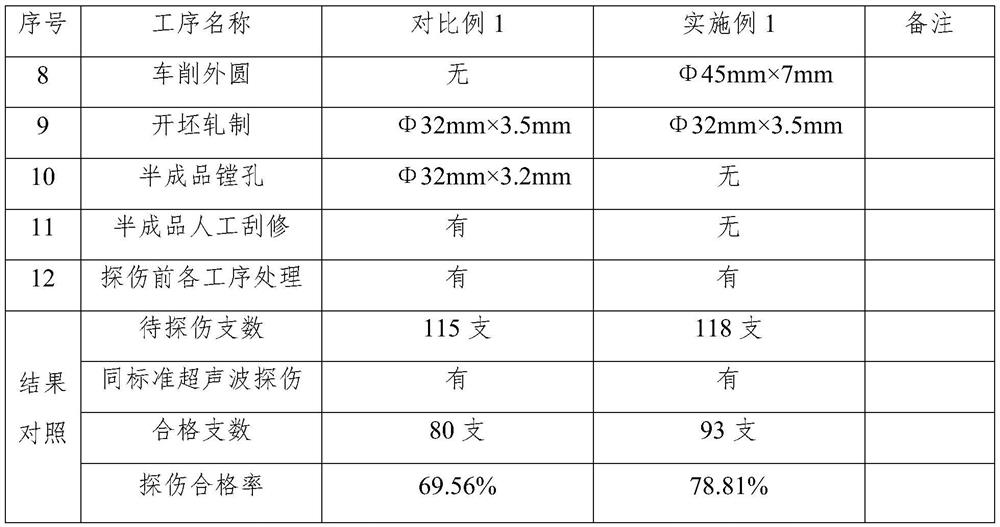

Machining method for improving ultrasonic flaw detection qualification rate of titanium alloy super-long seamless pipe

The invention discloses a processing method for improving the ultrasonic flaw detection qualification rate of a titanium alloy super-long seamless pipe, a pipe blank pre-preparation process is carried out before cogging rolling in a titanium alloy pipe preparation process, and the pipe blank pre-preparation process comprises pipe blank pre-rolling, inner surface boring and outer surface turning. The pipe blank pre-preparation process is carried out before cogging rolling in an existing titanium alloy pipe preparation process, so that the inner and outer diameter deviation of the pipe blank is effectively reduced, the defects of the inner and outer surfaces of the pipe blank are eliminated or reduced, the pipe blank meeting the process requirements is obtained, generation and expansion of cracks on the inner and outer surfaces of the pipe in the subsequent machining process are greatly reduced, and the production efficiency is improved. Therefore, the ultrasonic flaw detection qualification rate of the titanium alloy super-long seamless pipe is increased, the obtained product is high in precision and good in stability, the product quality is met and stabilized, meanwhile, the machining efficiency is improved, and the ultrasonic flaw detection device is convenient to popularize and use.

Owner:西安西部新锆科技股份有限公司

Production method of tempered high-strength Q550E super-thick steel plate

ActiveCN103540870AMeet the needs of heavy machinery manufacturingMeet the requirements of mechanical manufacturingSteelmakingHigh intensity

The invention provides a production method of a tempered high-strength Q550E super-thick steel plate. The production method comprises the processing steps of molten steel pre-treatment, converter steelmaking, external refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, off-line quenching, tempering, finishing, performance examination and ultrasonic flaw detection, and is characterized in that steel comprises the following chemical components: not more than 0.16% of C, 0.20-0.40% of Si, 1.45-1.60% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.05 of Nb and Ti, not more than 1.0% of Ni, 0.30-0.50% of Cr, 0.30-0.50% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities; CEV (carbon equivalent) is controlled to be not more than 0.60 and is computed according to the formula C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm tempered high-strength Q550E super-thick steel plate meets the requirements for manufacturing heavy machinery for mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q500F super-thick steel plate

ActiveCN103555909BMeet the requirements of mechanical manufacturingReduce manufacturing costHigh intensityQuenching

The invention relates to a production method of a quenched and tempered high-strength Q500F super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.15% of C, 0.20-0.40% of Si, 1.00-1.30% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of AlT, not more than 0.10% of Nb+Ti+V, not more than 1.0% of Cu+Ni, 0.40-0.70% of Cr, 0.30-0.60% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.58, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q500F super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q890E super-thick steel plate

ActiveCN103555911BMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingImpurity

The invention relates to a production method of a quenched and tempered high-strength Q890E super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.30-1.40% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.05% of Als, not more than 0.10% of Nb+V+Ti, not more than 1.0% of Cu+Ni, 0.30-0.50% of Cr, 0.45-0.70% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q890E super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q690E super-thick steel plate

ActiveCN103556061BMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingImpurity

The invention relates to a production method of a quenched and tempered high-strength Q690E super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.14% of C, 0.20-0.40% of Si, 1.00-1.20% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.05% of Als, not more than 0.10% of Nb+V+Ti, not more than 1.0% of Cu+Ni, 0.40-0.60% of Cr, 0.45-0.70% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.57, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q690E super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q620F super-thick steel plate

ActiveCN103556082BMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingImpurity

The invention relates to a production method of a quenched and tempered high-strength Q620F super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.40-1.60% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.06% of Nb+Ti, not more than 1.0% of Cu+Ni, 0.30-0.60% of Cr, 0.30-0.50% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q620F super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of quenched and tempered high-strength Q690D super-thick steel plate

ActiveCN103556077BMeet the requirements of mechanical manufacturingReduce manufacturing costHigh intensityQuenching

The invention relates to a production method of a quenched and tempered high-strength Q690D super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.00-1.30% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.10% of Nb+V+Ti, not more than 1.0% of Cu+Ni, 0.40-0.70% of Cr, 0.50-0.70% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q690D super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of tempered high-strength Q550E super-thick steel plate

ActiveCN103540870BMeet the requirements of mechanical manufacturingReduce manufacturing costSteelmakingPre treatment

The invention provides a production method of a tempered high-strength Q550E super-thick steel plate. The production method comprises the processing steps of molten steel pre-treatment, converter steelmaking, external refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, off-line quenching, tempering, finishing, performance examination and ultrasonic flaw detection, and is characterized in that steel comprises the following chemical components: not more than 0.16% of C, 0.20-0.40% of Si, 1.45-1.60% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.05 of Nb and Ti, not more than 1.0% of Ni, 0.30-0.50% of Cr, 0.30-0.50% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities; CEV (carbon equivalent) is controlled to be not more than 0.60 and is computed according to the formula C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm tempered high-strength Q550E super-thick steel plate meets the requirements for manufacturing heavy machinery for mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Production method of tempered high-strength Q620D super-thick steel plate

ActiveCN103540865BMeet the requirements of mechanical manufacturingReduce manufacturing costSteelmakingPre treatment

The invention provides a production method of a tempered high-strength Q620D super-thick steel plate. The production method comprises the processing steps of molten steel pre-treatment, converter steelmaking, external refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, off-line quenching, tempering, finishing, performance examination and ultrasonic flaw detection, and is characterized in that steel comprises the following chemical components: not more than 0.16% of C, 0.20-0.40% of Si, 1.40-1.60% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.06 of Nb and Ti, not more than 1.0% of Cu and Ni, 0.30-0.60% of Cr, 0.30-0.50% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities; CEV (carbon equivalent) is controlled to be not more than 0.60 and is computed according to the formula C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm tempered high-strength Q620D super-thick steel plate meets the requirements for manufacturing heavy machinery for mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

A production method of quenched and tempered high-strength q800e extra-thick steel plate

ActiveCN103556060BMeet the requirements of mechanical manufacturingReduce manufacturing costQuenchingImpurity

The invention relates to a production method of a quenched and tempered high-strength Q800E super-thick steel plate. The process steps are as follows: pretreatment of molten iron, steel-making by a converter, secondary refining, continuous casting (dynamic soft reduction and electromagnetic stirring), heating, rolling, pre-straightening, online quenching, offline quenching, tempering, finishing, performance testing and ultrasonic flaw detection. Steel comprises the following chemical components in percentage by weight: not more than 0.16% of C, 0.20-0.40% of Si, 1.10-1.30% of Mn, not more than 0.015% of P, not more than 0.003% of S, 0.03-0.06% of Als, not more than 0.10% of Nb+V+Ti, not more than 1.0% of Cu+Ni, 0.40-0.75% of Cr, 0.50-0.75% of Mo, not more than 0.0025% of B and the balance of Fe and inevitable impurities. The CEV (carbon equivalent) is controlled to be not more than 0.60, and the CEV is calculated according to the following formula: CEV=C+Mn / 6+(Cr+Mo+V) / 5+(Ni+Cu) / 15. The produced high-performance 100-120mm quenched and tempered high-strength Q800E super-thick steel plate can meet the needs for manufacturing heavy machinery in mines, ports and the like.

Owner:HUNAN VALIN XIANGTAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com