Anti-slide single-rubber-barrel downhole throttling device

A throttling device and anti-slip technology, which is applied in the direction of mining fluid, wellbore/well components, earthwork drilling and production, etc., can solve problems such as testing, choke drop at the bottom of the well, permanent deformation of the rubber tube, etc., and reach the service life Stable, avoid slipping down the bottom of the well, good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

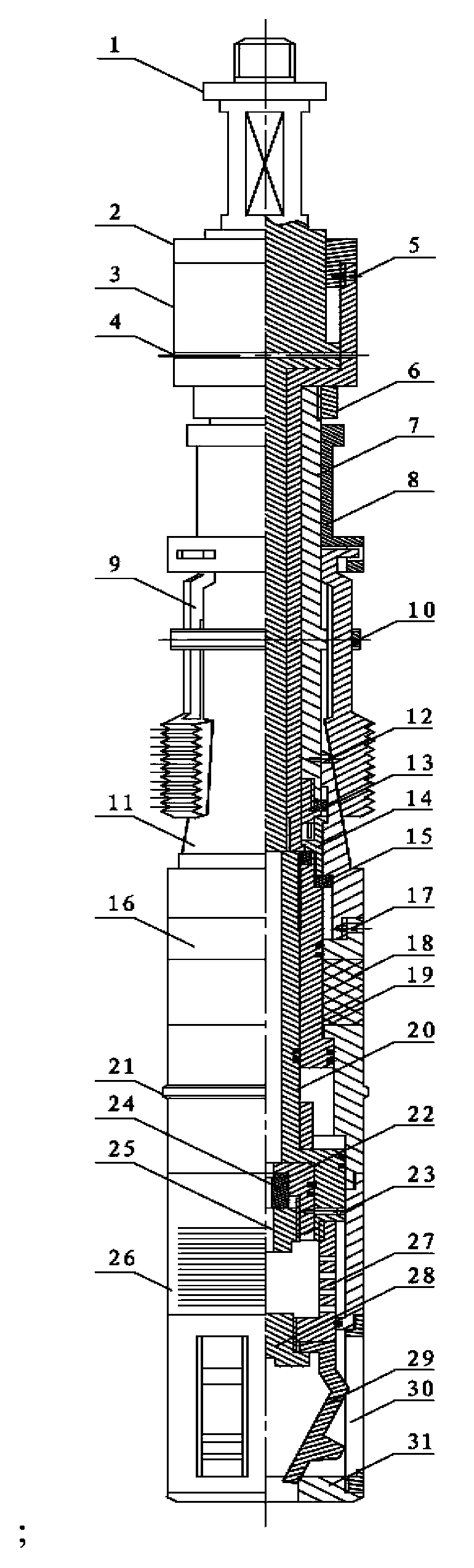

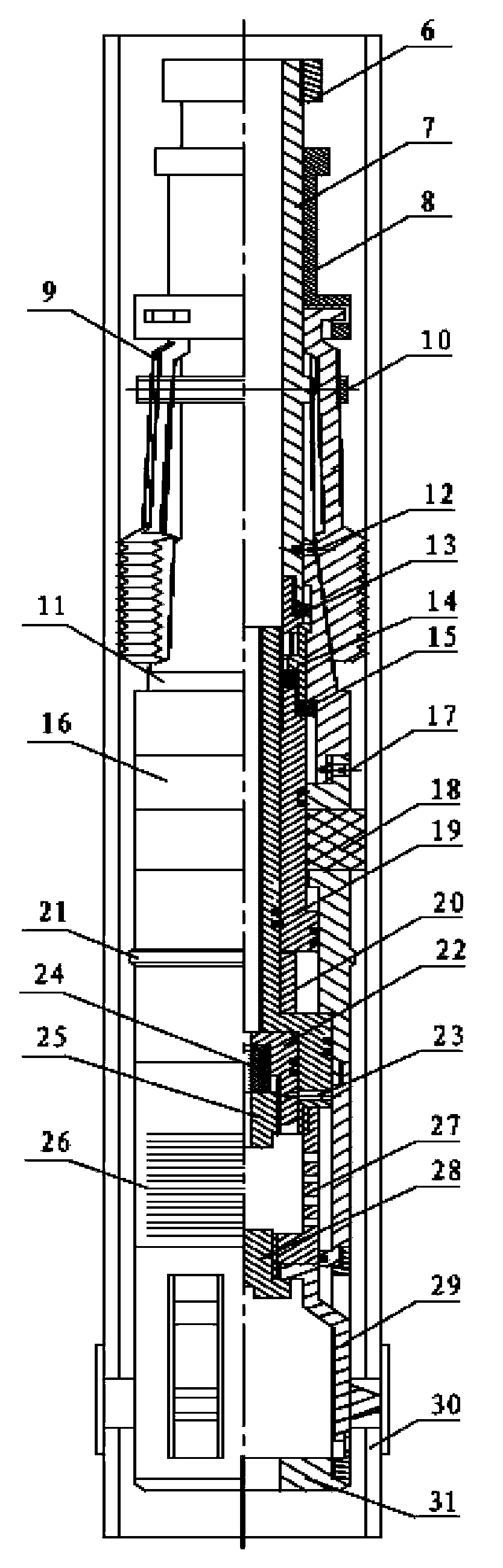

[0019] The top of the expanding diameter cylinder on the upper part of the locking sleeve 3 is threadedly connected to the gland 2 and locked by the screw 5 . The dispenser 1 passes through the gland 2, and its upper diameter-expanding rod is fixed in the upper diameter-expanding cylinder of the locking sleeve 3 by radial pins 4, and its lower diameter-reducing rod is inserted into the lower diameter-reducing cylinder of the locking sleeve 3.

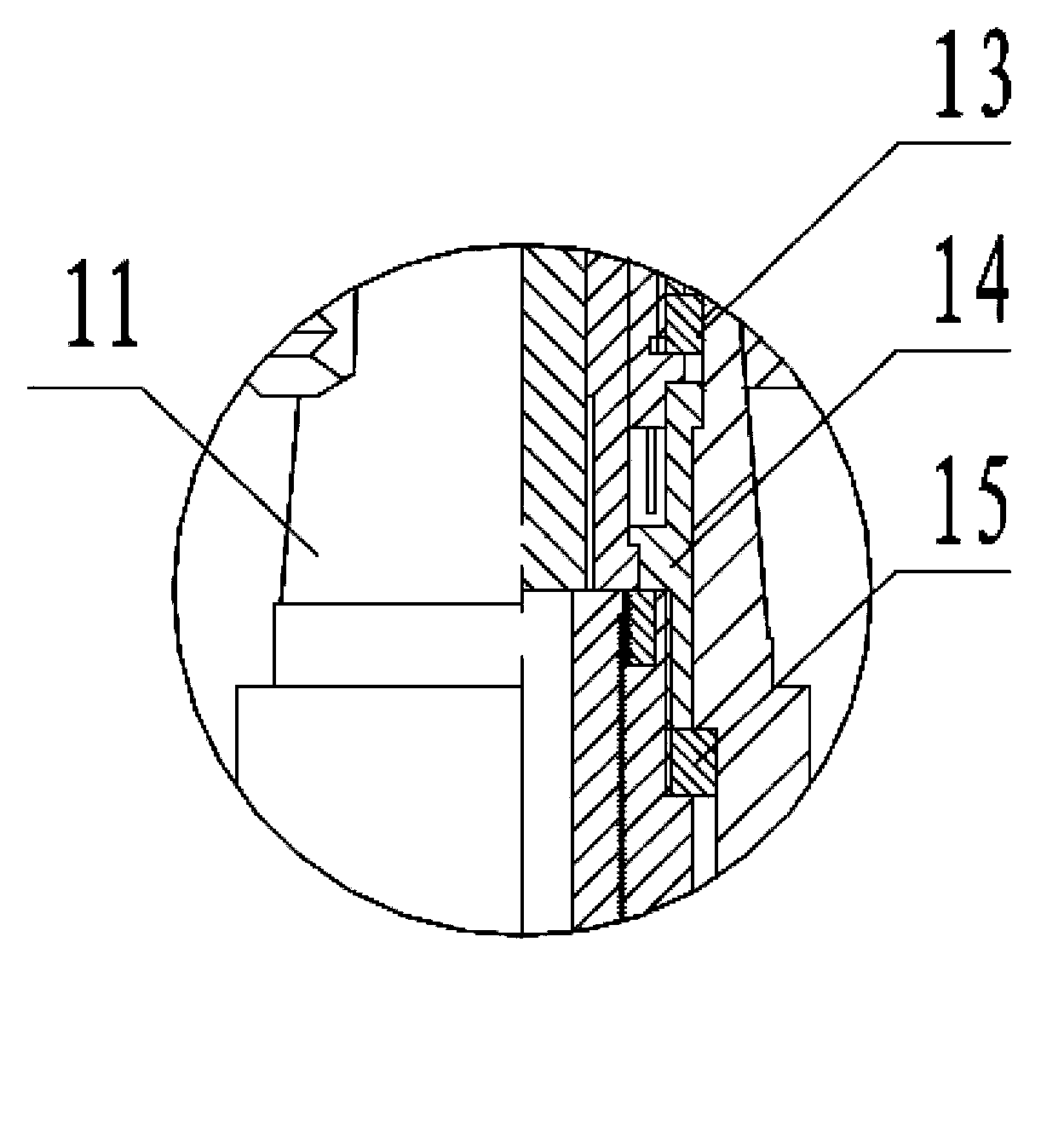

[0020] The locking sleeve 3 is fitted with the body 7 on the outer wall of the reducing tube, and the top of the body 7 is threaded to connect with the salvage retaining ring 6, and then the salvage head 8, the slips 9 and the slip support sleeve 11 are sequentially fitted. The top of the slip 9 snaps into the hook groove at the bottom of the fishing head 8, and is locked in the slip seat on the outer wall of the body 7 by the lock sleeve 10. The slip support sleeve 11 is fixed to the bottom of the body 7 by the salvage pin 12 , and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com