Air flotation type rotary table

A technology of air-floating turntables and air-floating sleeves, which is applied in the direction of air cushion bearings, machines/brackets, large fixed members, etc., can solve the problems of poor accuracy and stability, and achieve the effect of improving axial static stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and specific embodiment, the present invention will be further described:

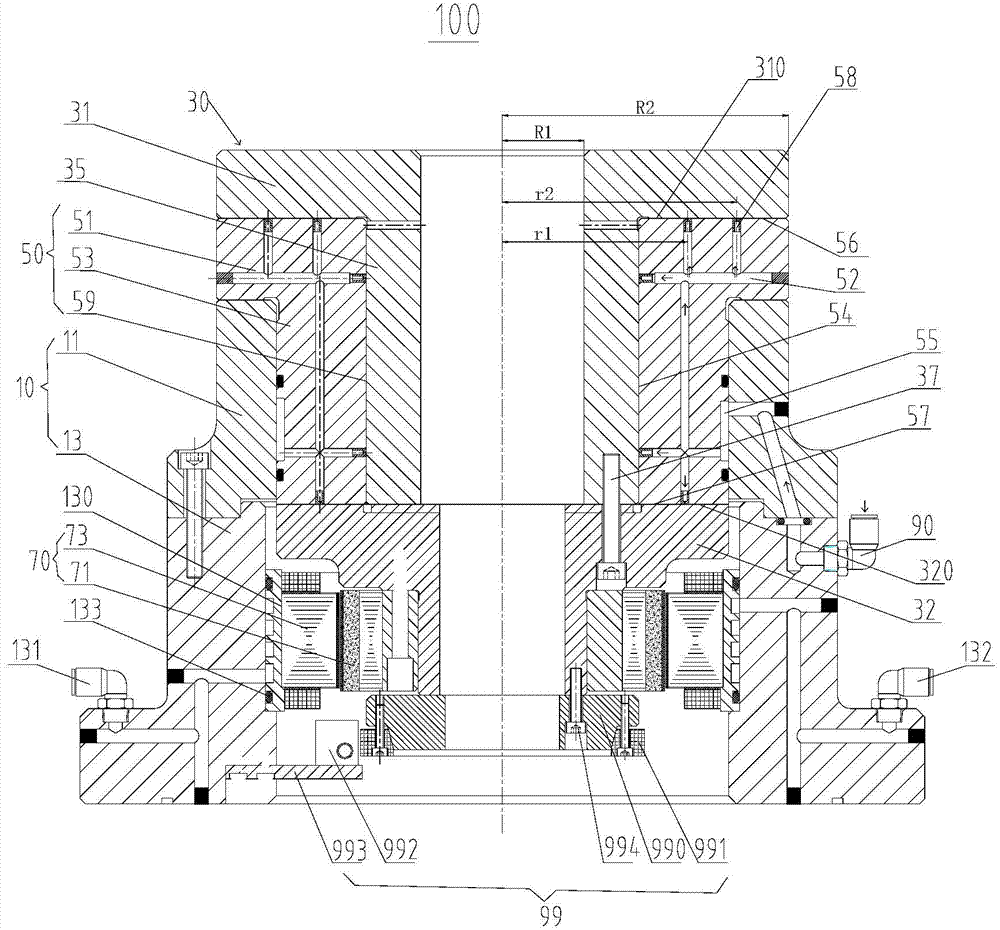

[0019] See figure 1 , the present invention relates to an air bearing turntable 100 , which includes a base 10 , an air bearing shaft 30 , an air bearing sleeve 50 , a torque motor 70 , an air inlet pipe 90 and a reading device 99 . The air bearing 50 is installed on the base 10 . The air bearing shaft 30 is set in the air bearing sleeve 50 . The bottom 32 is connected with the air bearing shaft 30 and can float upward with the air bearing shaft 30 relative to the air bearing sleeve 50 when the air intake pipe 90 is ventilated, and at the same time rotate relative to the air bearing sleeve 50 under the action of the torque motor 70 . The readout device 99 is used to control the rotational speed or positioning of the torque motor 70 .

[0020] The base 10 includes an upper base 11 and a lower base 13 connected to the upper base 11 . The upper bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com