A method and device for converting a fault monitored by an external controller into a fault check code in an electronic control system

An external controller and fault detection technology, applied in the field of fault check codes, can solve problems such as waste, inability to determine external controller faults, and inability to meet the requirement that the number of SPNs is greater than 80, and achieves the effect of flexible calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

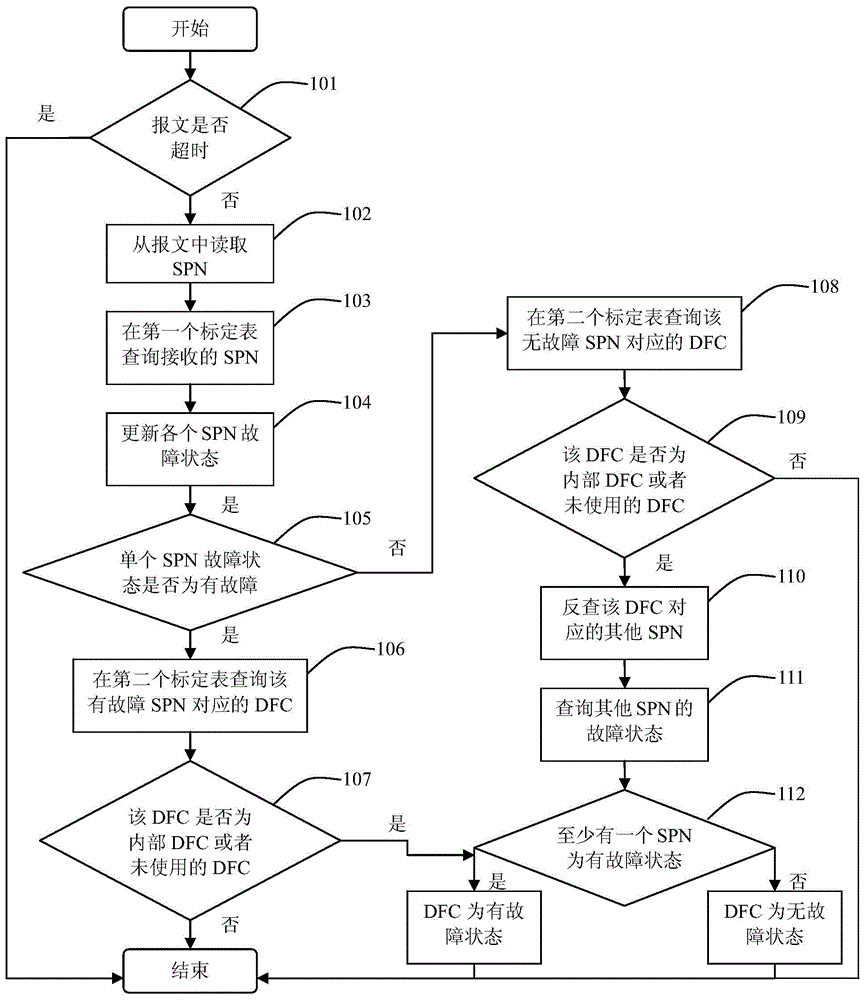

[0032] The present invention provides two calibration tables for the corresponding relationship between SPN and DFN required by the calibration system when managing the faults detected by the external controller, and provides two calibration tables based on the present invention, the system according to the external The SPN received by the controller gets the flow of the DFC status.

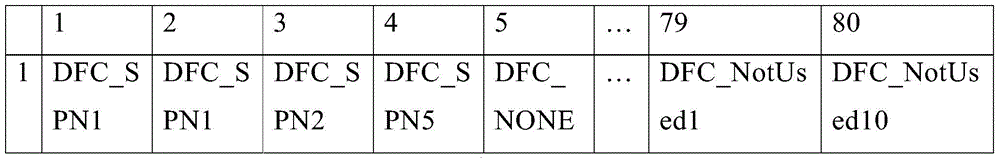

[0033] The first calibration table is used to calibrate the SPNs that the system needs to manage. The second calibration table is used to calibrate the DFC that the system needs to manage. The DFC calibrated in a certain cell corresponds to the SPN of the corresponding cell in the first table, that is to say, the correspondence between DFC and SPN depends on the first calibration. The one-to-one correspondence between the cells of the table and the cells of the second calibration table is maintained.

[0034] For the convenience of calibration and the clarity and simplicity of the corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com