Rotor structure of vehicular generator

A technology of rotor structure and generator, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit rotating parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

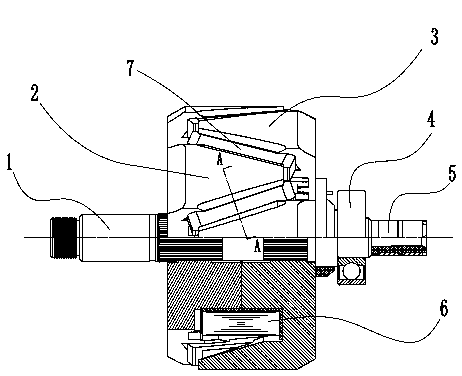

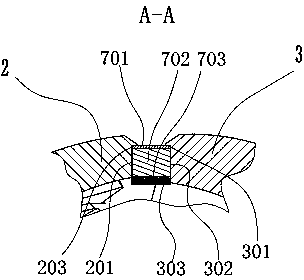

[0036] The front and rear ends and the bottom surface of the permanent magnet 702 are wrapped by the bottom shell 703, the top surface is wrapped by a metal support plate 701, and the front and rear ends of the bottom shell 703 are pasted by heat sealing (or glue coating) On the pole tip 204 of the front claw pole 2 and the pole tip 304 of the rear claw pole 3 . The left and right sides of the encapsulated permanent magnet 7 are respectively fixed by the side surface 201 of the front claw pole 2 and the lower surface 302 of the rear claw pole 3; the metal support plate 701 is positioned by the upper surface 203 of the front claw pole 2 and the side surface 301 of the rear claw pole 3; The bottom shell 703 is positioned by the lower surface 202 of the front claw pole 2 and the upper surface 303 of the rear claw pole 3 to achieve the purpose of fixing and encapsulating the permanent magnet 7 .

[0037] Example 2

Embodiment 2

[0039]The front and rear ends and bottom surface of the permanent magnet 702 are wrapped by the bottom shell 703, and the top surface is wrapped by a metal support plate 701. The front end of the bottom shell 703 is provided with a single hook 703a, and the rear end is provided with the single hook 703a. The hook 703a is a protrusion 703b with the hook mouth reversed, the single hook 703a is stuck at the pole tip 204 of the front claw pole 2, and the boss 703b is stuck at the pole tip 304 of the adjacent rear claw pole 3 or the single hook 703a is stuck on the pole tip 304 of the rear claw pole 3, and the boss 703b is stuck on the pole tip 204 of the adjacent front claw pole 2, so as to fix and package the permanent magnet 7 purposes.

[0040] Example 3

Embodiment 3

[0042] The front and rear ends and the bottom surface of the permanent magnet 702 are wrapped by the bottom shell 703, and the top surface is wrapped by a metal support plate 701. The front end of the bottom shell 703 is provided with double hooks 703c, and the rear end is provided with a boss 703b. One hook of the double hook 703c is stuck on the pole tip 204 of the front claw pole 2, the other hook is unfolded and stuck on the end of the side 301 of the rear claw pole 3, and the boss 703b is stuck on the On the pole tip 304 of the rear claw pole 3, or one hook of the double hook 703a is stuck on the pole tip 304 of the rear claw pole 3, and the other hook is unfolded and stuck on the side 201 end of the front claw pole 2 part, the boss 703b is clamped on the pole tip 204 of the front claw pole 2, so as to achieve the purpose of fixing and encapsulating the permanent magnet 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com