Hydraulic soft start motor

A soft start and motor technology, applied in the field of electric motors, can solve the problems such as failure to implement energy saving and consumption reduction requirements, large selection of power, and failure to meet the original design requirements for debugging, so as to alleviate the impact of the starting current on the power grid, reduce the starting current, The effect of strong self-overload protection function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

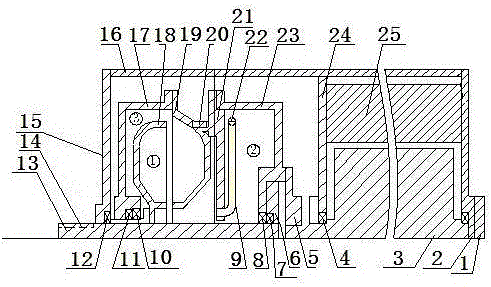

[0020] see figure 1 , the hydraulic soft start motor of the present invention is equipped with motor stator 25, motor rotor 3, front auxiliary chamber housing 23, pump wheel 19, worm wheel 18, rear auxiliary chamber housing 17 and output shaft in motor housing 16 13. The motor rotor 3 is connected and fixed to the front auxiliary chamber casing 23 through the connecting plate 5, the front auxiliary chamber casing 23 is connected and fixed to the pump wheel 19 through the connecting plate 5, and the pump wheel 19 is connected and fixed to the rear auxiliary chamber casing 17. The worm wheel 18 is connected and fixed with the output shaft 13; the pump wheel 19 and the worm wheel 18 constitute the soft start working chamber, the worm wheel 18 and the rear auxiliary chamber housing 17 form the rear auxiliary chamber, and the front auxiliary chamber housing 23 and the pump wheel 19 form the front auxiliary chamber. The front auxiliary chamber communicates with the soft start workin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com