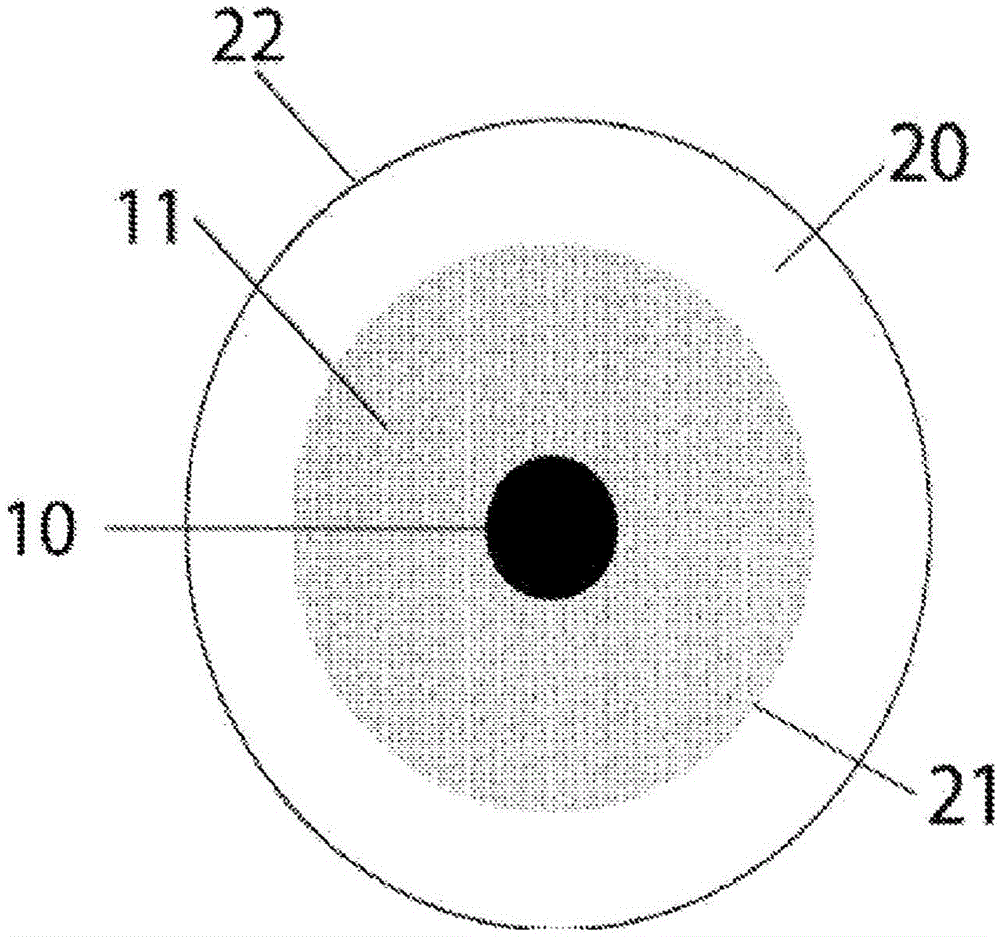

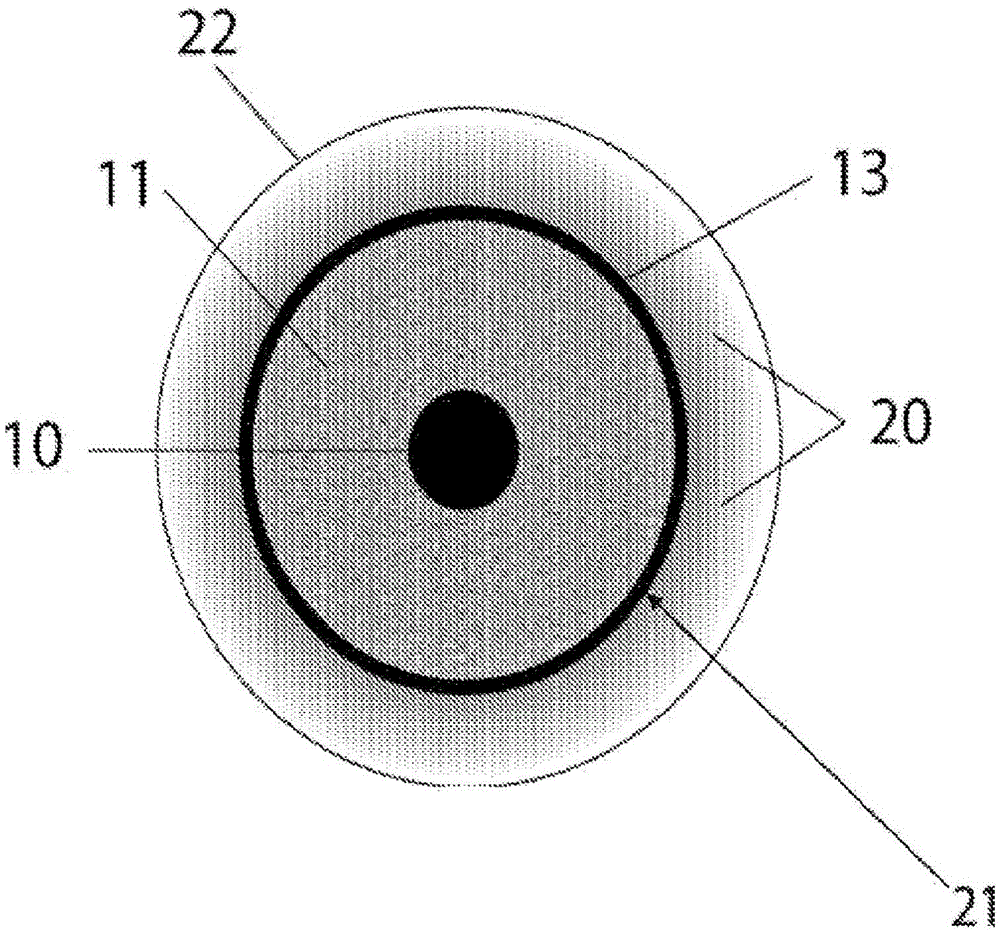

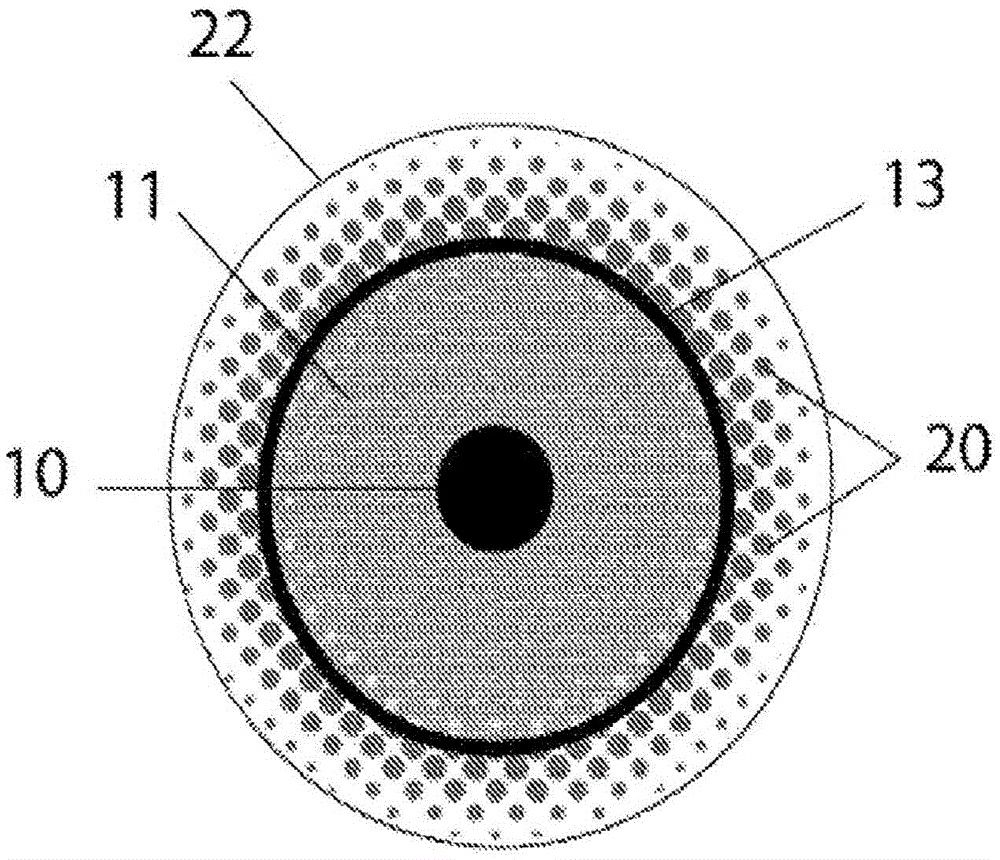

Contact lenses with brightly stained sclera

A contact lens and lens technology, applied in glasses/goggles, optics, instruments, etc., can solve problems such as not getting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0031] Example 1: preparation of transparent master ink composition

[0032] The binding polymer used 96 g of 1-dodecanethiol ("DODT"), 56.54 g of lauryl methacrylate ("LMA"), 7.40 g of methacrylic acid ("MAA"), 1367 g of methyl Hydroxyethyl acrylate ("HEMA"), 68.5 g of glycerin, 378 g of 1-ethoxy-2-propanol ("EP"), 1511 g of isopropyl lactate ("IPL"), and 8.89 g of 2, 2'-Azobis(2-methylbutyronitrile) ("AMBN"). DODT, monomer and solvent (except for about 50-100 cc of IPL) were first mixed in a 5 liter blue cap bottle and stirred for 10 minutes. The mixture was then poured into a 5 L stainless steel reactor with stirrer and nitrogen. The mixture was stirred and heated for about 25 minutes until the temperature was 68°C. After the temperature stabilized at 68 °C, AMBN was dissolved in the remaining IPL and added while turning on the nitrogen vent. Polymerization was allowed to proceed for 16-24 hours after which time the temperature was increased to 80°C and the reaction w...

example 2

[0033] Example 2: Preparation of black ink

[0034] By weighing 243.47g of 1D Black Define (made of 11.76% by weight of black iron oxide pigment (FeO.Fe 2 o 3 , CAS No. 12227-89-3) constituted) was added to a 400mL glass jar to prepare a black pad printing ink. 6% by weight of 1-propanol was also added to the jar. Place the jar under a stirrer and stir at 1800 rpm until the ink is uniform in appearance.

example 3

[0035] Example 3: Preparation of white ink

[0036] By weighing 49.98g of the original white pigment (primary white) (made of 30.00% by weight of titanium dioxide pigment (TiO2) in the transparent mother ink as described in Example 1 2 , CAS No. 13463-67-7)) was added to a 250mL glass jar to prepare a white pad printing ink. 100.00 g of clear master ink (described in Example 1) and 6% by weight of 1-propanol were also added to the jar. Place the jar under a stirrer and stir at 1800 rpm until the ink is uniform in appearance.

[0037] Starting from the inks described herein, colored lenses are prepared using methods and apparatus known in the art. These include, for example, the methods described in US Patent Publication 20090244479, which is incorporated herein by reference.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com