Corrosion crack welding restoration method and material for regenerator

A technology of welding repair and stress corrosion cracking, which is applied in the direction of welding/cutting medium/material, welding medium, welding equipment, etc., can solve problems such as stress corrosion of regenerators, and achieve the effect of prolonging service life and avoiding cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0017] Welding repair methods are divided into pre-welding preparation procedures, welding repair procedures and post-welding inspection procedures, as follows.

[0018] 1 Preparation process before welding

[0019] (1) Eliminate defects: Use carbon arc gouging (or grinder) to polish and clean the defective parts until all the defects are eliminated.

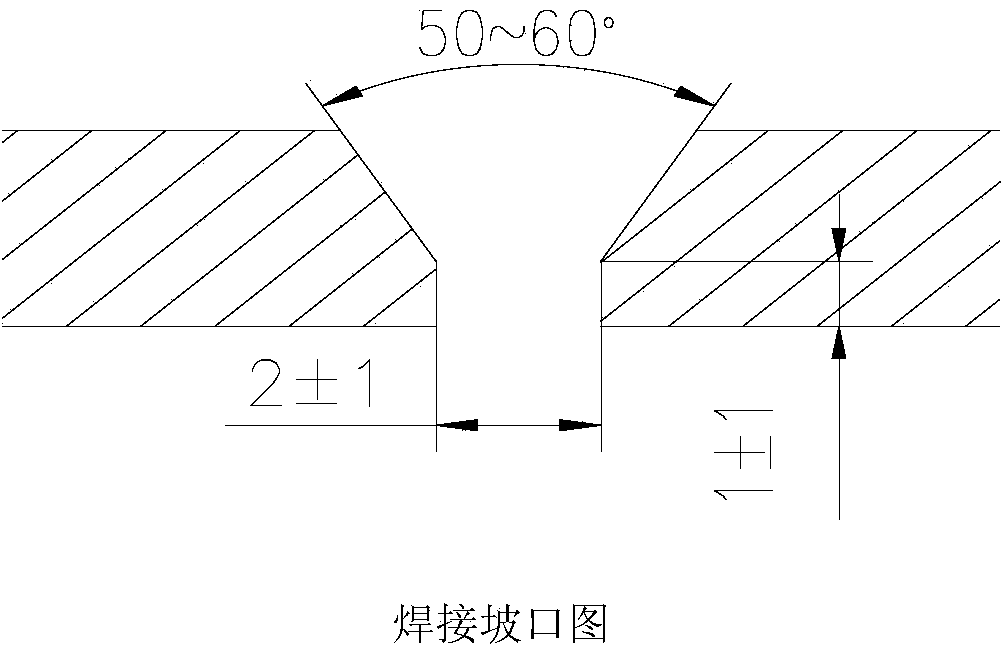

[0020] (2) Grinding the groove: the angle between the slopes on both sides of the groove is 50°~60°, the groove length direction is consistent with the crack direction, and the groove length is ≥100mm. When the crack penetrates the wall thickness, the gap between the two sides of the groove on the inner surface is not more than 2±1mm.

[0021] (3) Defect detection: According to the requirements of JB / T4730, special flaw detectors will perform surface flaw detection (magnetic powder or coloring) to confirm that all surface flaws in the groove area are removed. If they are not removed, they should be removed again until they are qualified...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com