A multi-layer pipe row hook

A technology of multi-layer tubes and hooks, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of difficult placement accuracy, low production efficiency, and inconvenient transportation, so as to facilitate large-scale use and improve Productivity, easy loading and unloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

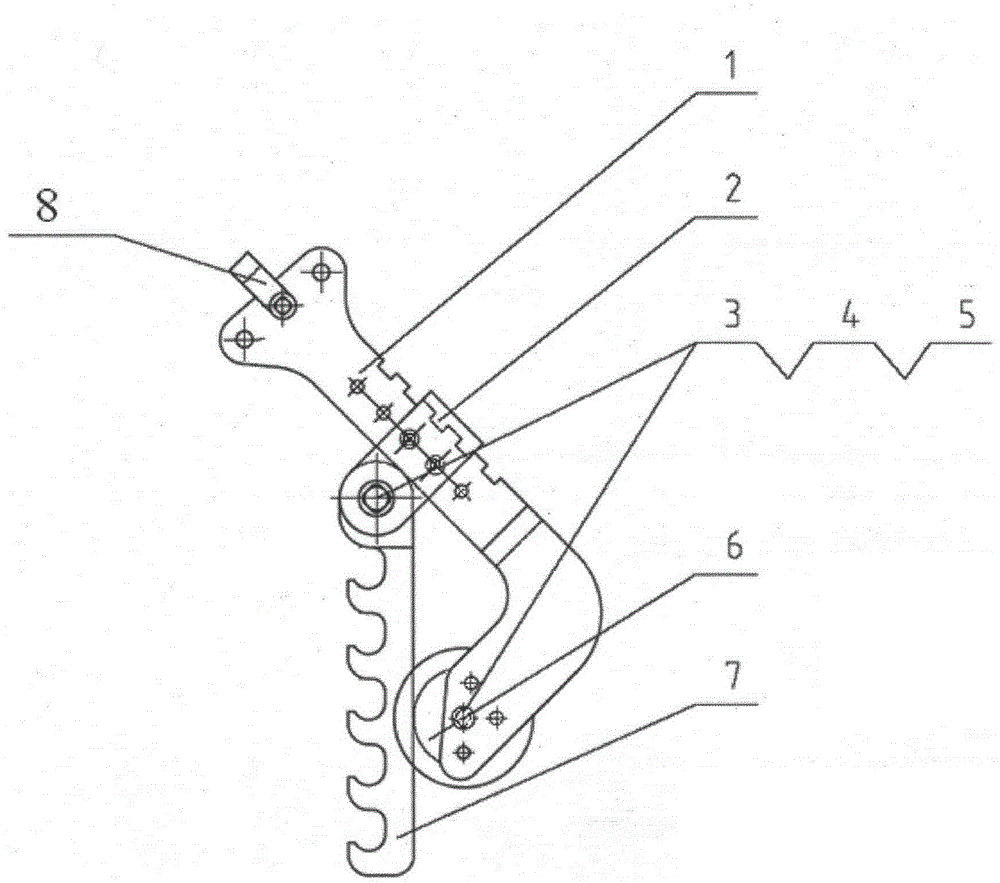

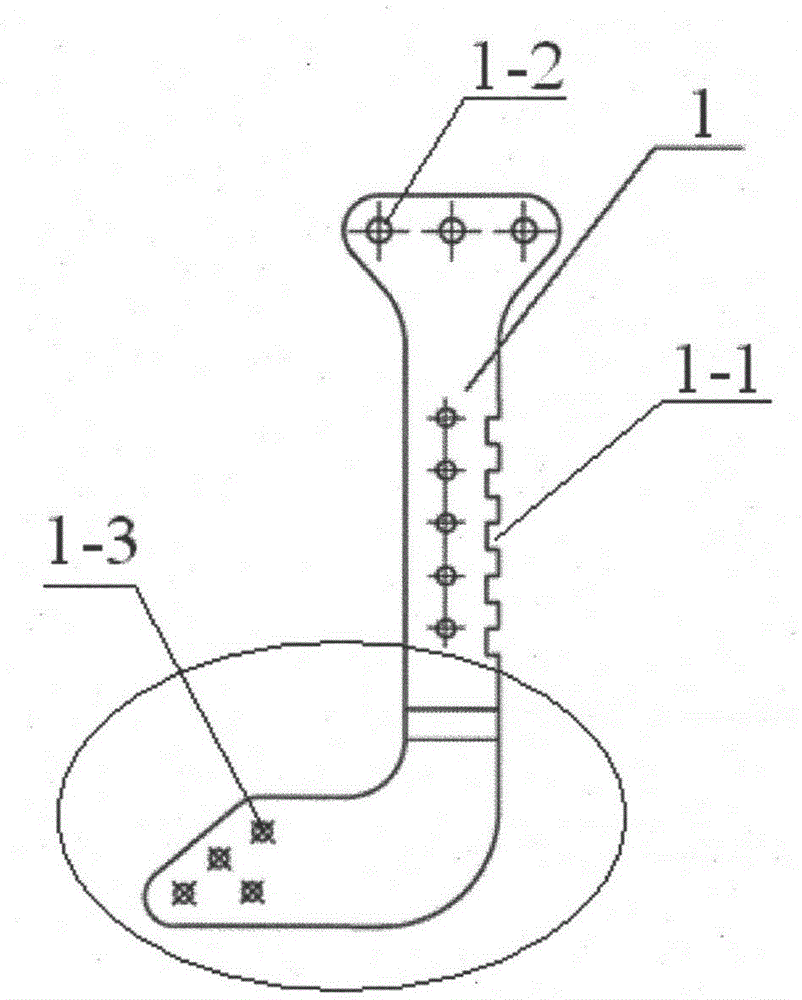

[0023] figure 1 Schematic diagram of the structure of the multi-layer pipe row hook provided by the present invention. The multi-layer pipe row hook includes a positioning hook 1, a connecting block 2, a pin with a hole 3, a nut 4, a gasket 5, a card wheel 6 and a lifting hook 7.

[0024] Concrete connection is as follows: positioning hook 1 and connection block 2 are installed at first, and lifting hook 7, card wheel 6 are installed afterwards. The connecting block 2 is installed on the positioning hook 1 , the card wheel 6 is installed on the bottom of the positioning hook 1 , and the lifting hook 7 is installed on the connecting block 2 . Between the connecting block 2 and the lifting hook 7, between the positioning hook 1 and the card wheel 6, all are connected by the pin with a hole 3, the nut 4, and the washer 5.

[0025]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com