Prefabricated space structure c-type node device

A space structure and prefabricated technology, which is applied in the direction of building structure and construction, can solve the problems of fast construction and large rigidity rotation of prefabricated steel structures at the same time, achieve fast construction speed, good rotational stiffness, and reduce construction difficulty and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

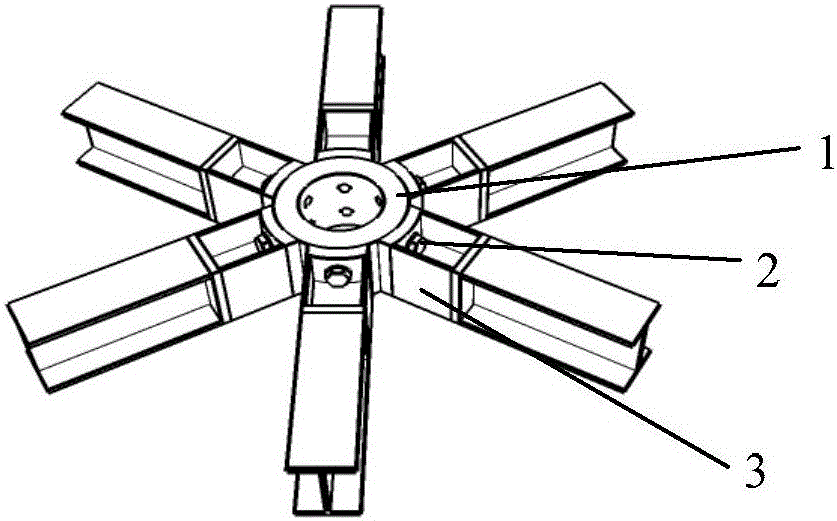

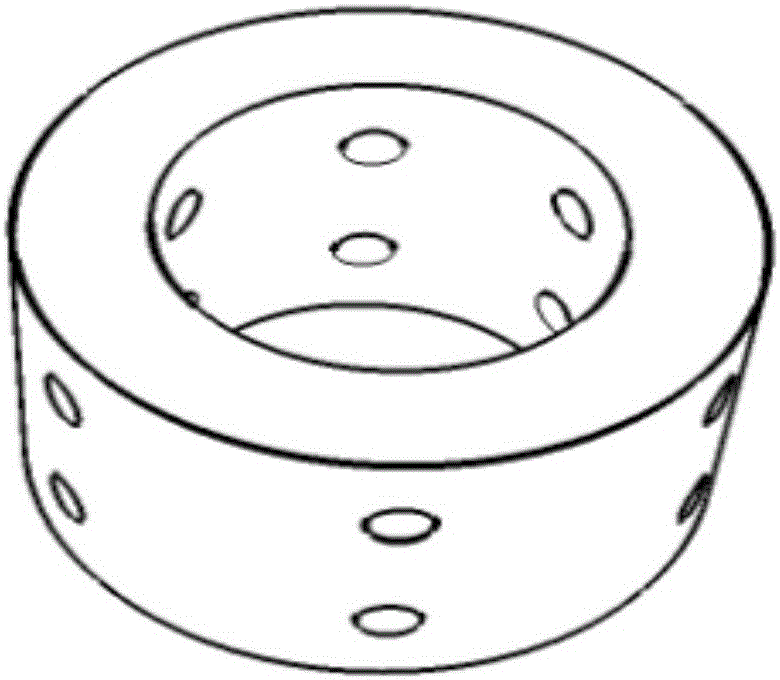

[0015] Specific embodiment one: the following combination figure 1 , figure 2 , image 3 , Figure 4 and Figure 7 Illustrating this embodiment, the assembled space structure C-type node device described in this embodiment includes n rods 3, and it also includes node cylinder 1 and 2n bolts 2; n is an integer between 2 and 10 ;

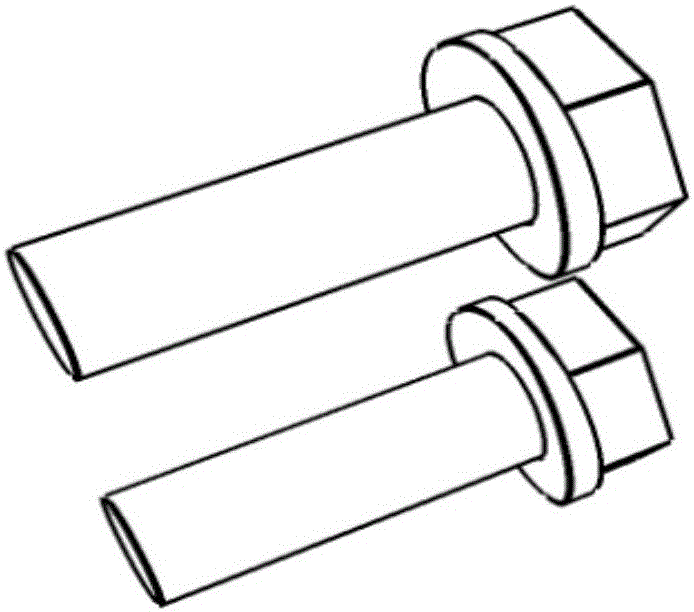

[0016] The outer diameter of the node cylinder 1 is R, the n rods 3 are centered on the axis of the node cylinder 1 and are evenly distributed outside the side wall of the node cylinder 1 in a radial shape, and the node connecting end face 31 of each rod 3 is the radius is the cylindrical surface of R, the node connecting end face of each rod 3 is in close contact with the outer wall of the node cylinder 1, and is fixedly connected to the side wall of the node cylinder 1 through two bolts 2,

[0017] All rods 3 have the same structure. Each rod 3 is divided into a fixed section 32 and an extended section along its length. The fixed section is an...

specific Embodiment approach 2

[0020] Embodiment 2: This embodiment further defines the C-type node device of the prefabricated space structure described in Embodiment 1. In this embodiment, n=6.

specific Embodiment approach 3

[0021] Specific implementation three: combination Figure 5 and Image 6 This embodiment is described. This embodiment further limits the prefabricated space structure C-type node device described in Embodiment 1. In this embodiment, the extension of each rod 3 is a round steel pipe, a rectangular steel pipe or a " "I" shaped steel members.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com