A steam generator capable of continuously injecting high-pressure steam

A technology of steam generator and high-pressure steam, which is applied in steam generation, steam generation methods, chemical instruments and methods, etc., and can solve the problems of pumping water and failing to lower it down

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

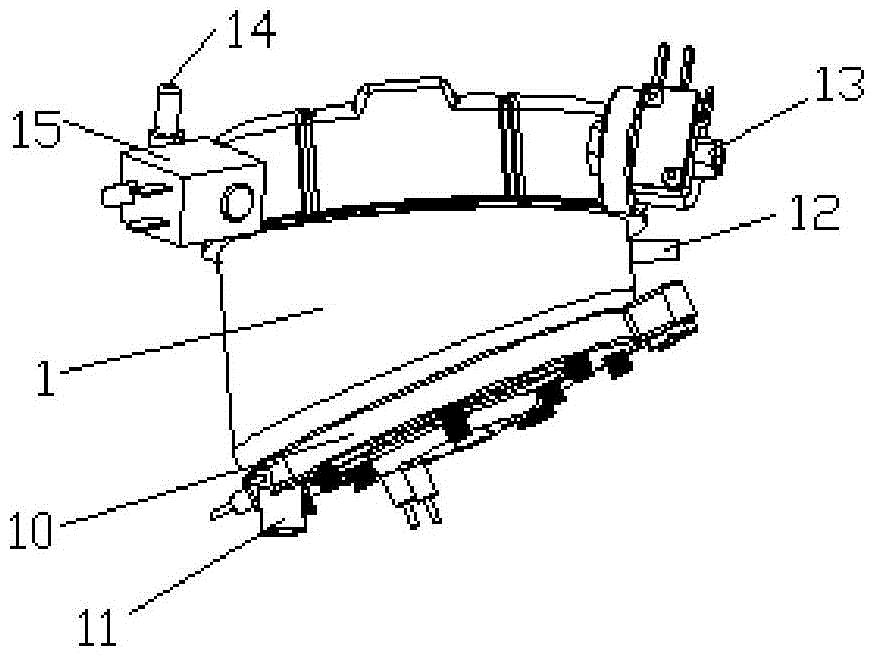

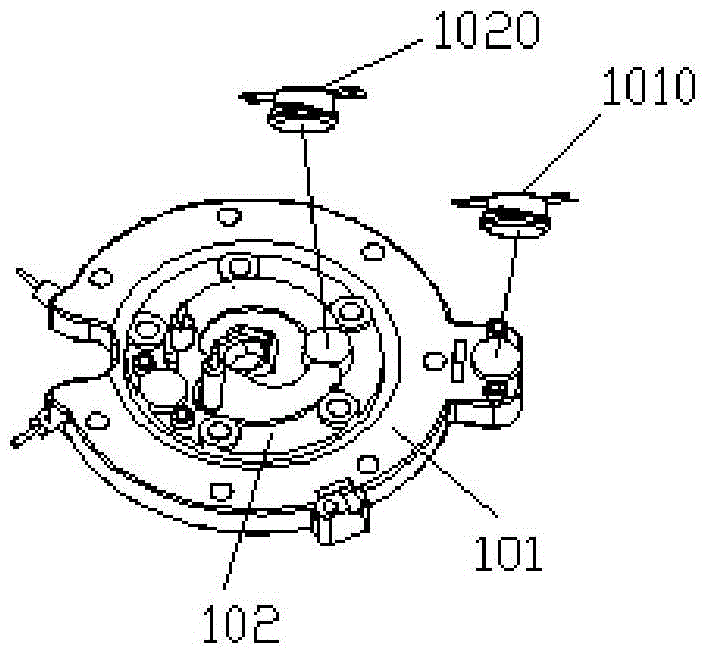

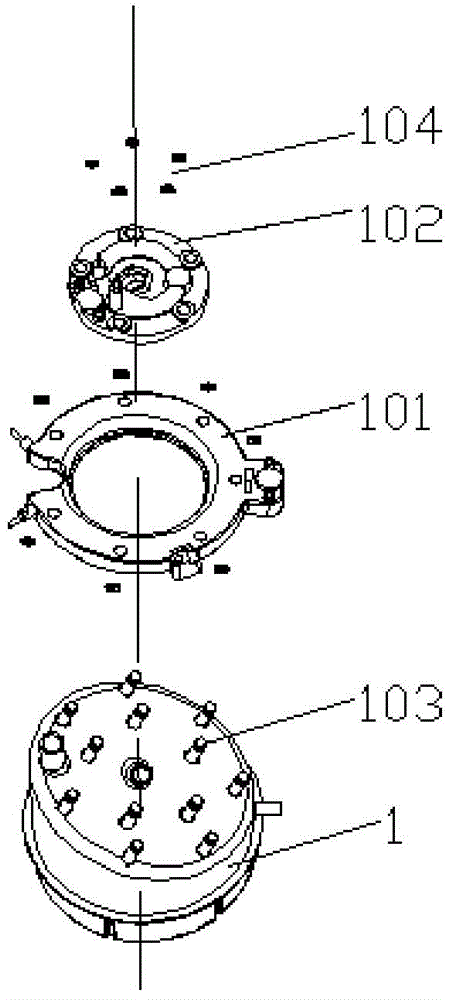

[0028] Combine below Figure 1 to Figure 6 Embodiment 1 of the present invention will be specifically described.

[0029] Such as figure 1 As shown, a steam generator that can realize continuous injection of high-pressure steam includes a vaporizer 1, the upper part of the vaporizer 1 is provided with a water inlet 12, a steam outlet 14, and a pressure switch 13, and the steam outlet 14 is provided with The solenoid valve 15, the water inlet 12 is connected to the water pump, the bottom of the vaporization pot 1 is provided with a sewage outlet 11, and the inner bottom of the vaporization pot 1 is provided with a heating element 10. Wherein, the inner bottom surface of the vaporization pot is arranged obliquely, and the heating element 10 includes at least two heating element units. There is a normally closed thermostat at the highest point. Specifically, in this embodiment, the bottom of the vaporization pot 1 is inclined, so that the inner bottom surface of the vaporizati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com