Steam conveying pipeline device for ironing of cloth spreading machine

A technology for conveying pipelines and spreading machines, applied in textiles and papermaking, fabric surface trimming, spraying/jetting textile material treatment, etc., to achieve outstanding effects, simple structure, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

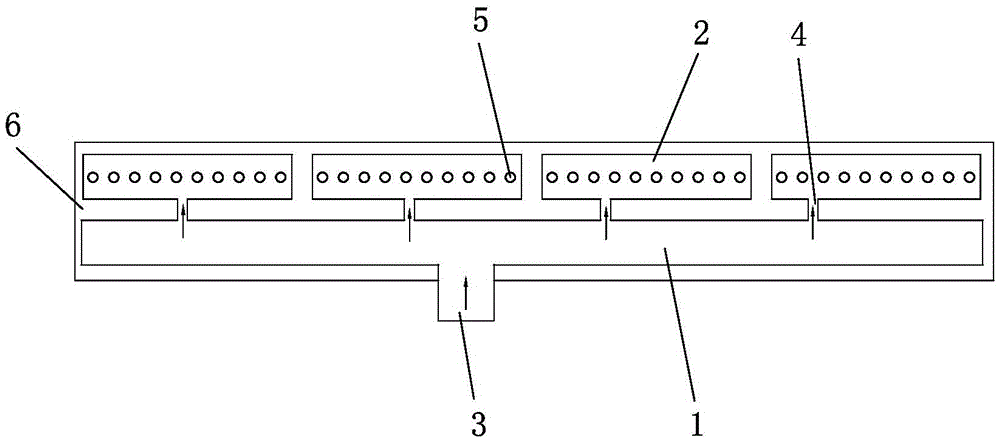

[0015] The present invention will be further described below with specific embodiment, see figure 1 :

[0016] A steam conveying pipeline device for ironing of a spreader, comprising a main steam pipeline 1 and several branch pipelines 2, the main steam pipeline 1 is provided with a main steam inlet 3 and connecting pipes 4 with several branch pipelines . Each branch pipe 2 communicates with the main steam pipe 1 through a branch pipe connecting pipe 4 , and each branch pipe 2 is provided with a nozzle connection hole 5 . The steam is input from the main steam inlet 3 and sent into the branch pipe 2 through the branch pipe connecting pipe 4 . The nozzle connecting holes 5 on each branch pipe 2 are provided in a row.

[0017] In the above technical solution, the main steam pipeline 1 and several branch pipelines 2 are arranged in the cavity surrounded by the heat insulation board 6 . The setting of the heat insulation board 6 can reduce the heat dissipation of the main stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com