Advanced adit hole-by-hole delayed blasting network in tunnel blasting

A detonation network and leading technology, applied in blasting and other directions, can solve problems such as failure to meet control requirements, achieve the effects of reducing throwing distance, reducing energy transfer, and reducing the impact of rock trapping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

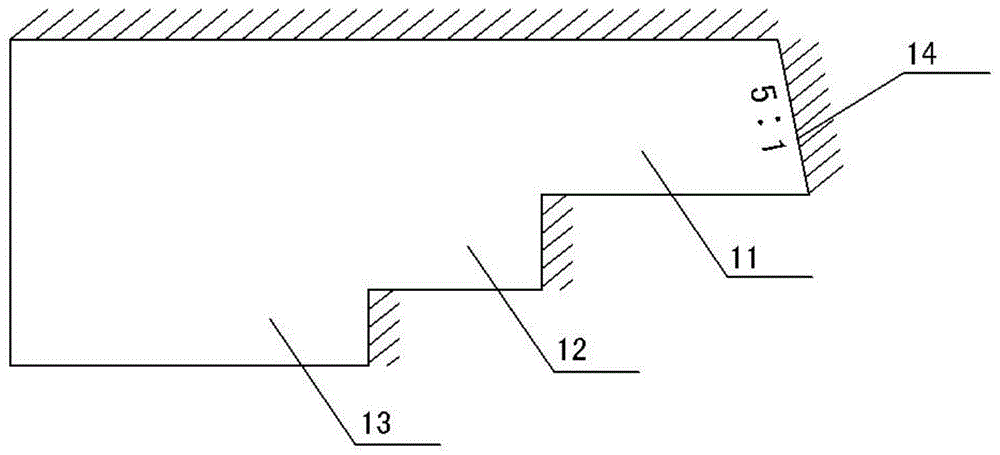

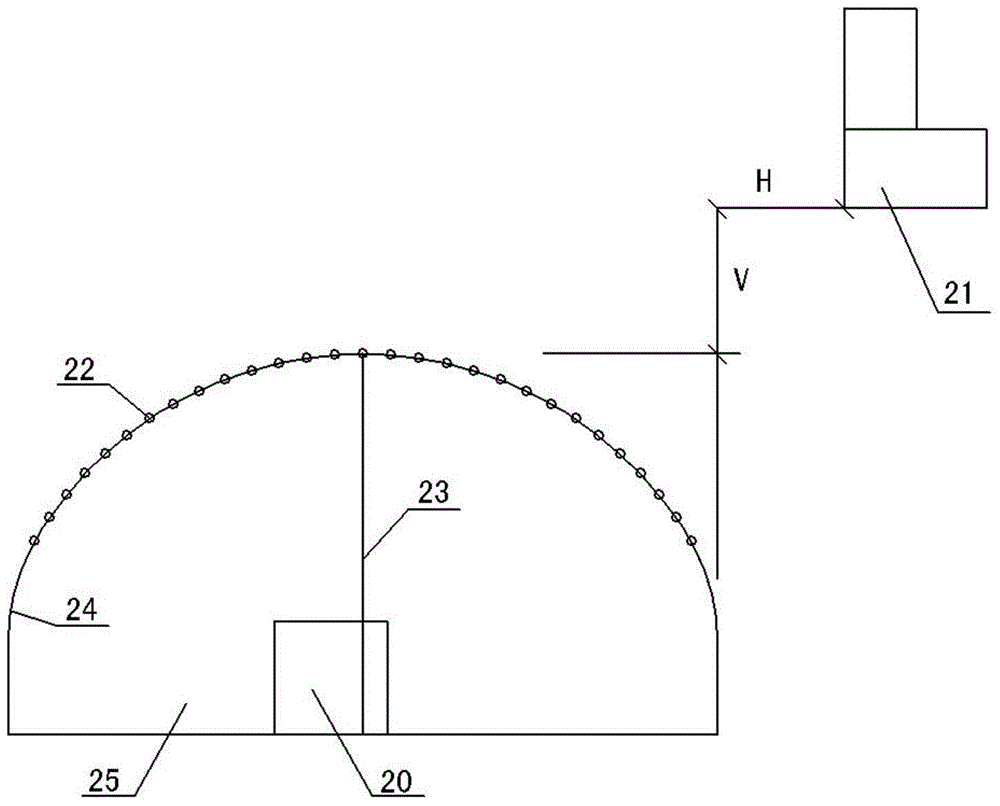

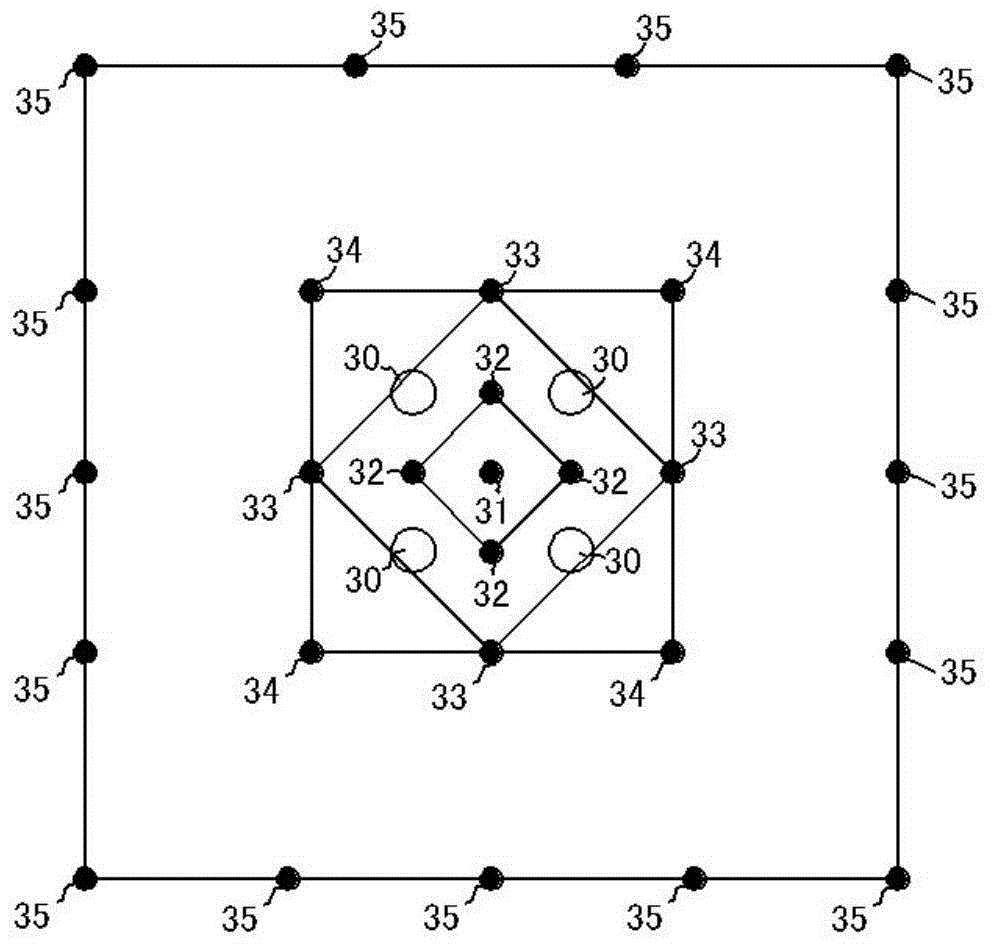

[0035] see figure 1 , in this embodiment, a comprehensive shock-absorbing method is implemented for the blasting of the tunnel passing through the culturally preserved buildings: for the subterranean excavation subway interval tunnel passing through the ancient culturally preserved buildings, the three-step method is used for drilling and blasting excavation, and the longitudinal excavation along the tunnel is sequentially formed. Upper step 11, middle step 12 and lower step 13. figure 1V shown in is the height difference between the foundation of the protected building and the tunnel vault, and H is the minimum distance between the foundation of the protected building and the tunnel excavation contour line. In the present embodiment, the value of V is 1.5 meters , H value is 16.3 meters. In this embodiment, the excavation method of three steps is adopted, and the longitudinal depth between the three steps is widened. After the blasting and excavation of the upper step is com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Circumferential spacing | aaaaa | aaaaa |

| Vertical spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com