Simplified analysis method for collision bending of thin-wall curved beam of automotive body

A technology of automobile body and analysis method, which is applied in the research of crashworthiness analysis and simplified analysis of collision and bending of thin-walled curved beams of automobile body, can solve problems such as inapplicability of calculation methods, improve simulation accuracy and calculation efficiency, and shorten design effect of cycles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] specific implementation plan

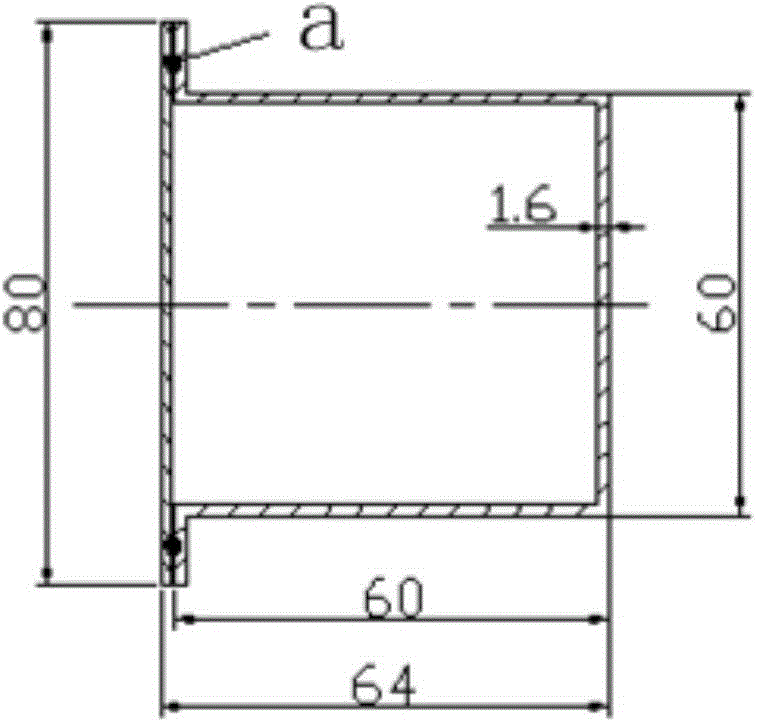

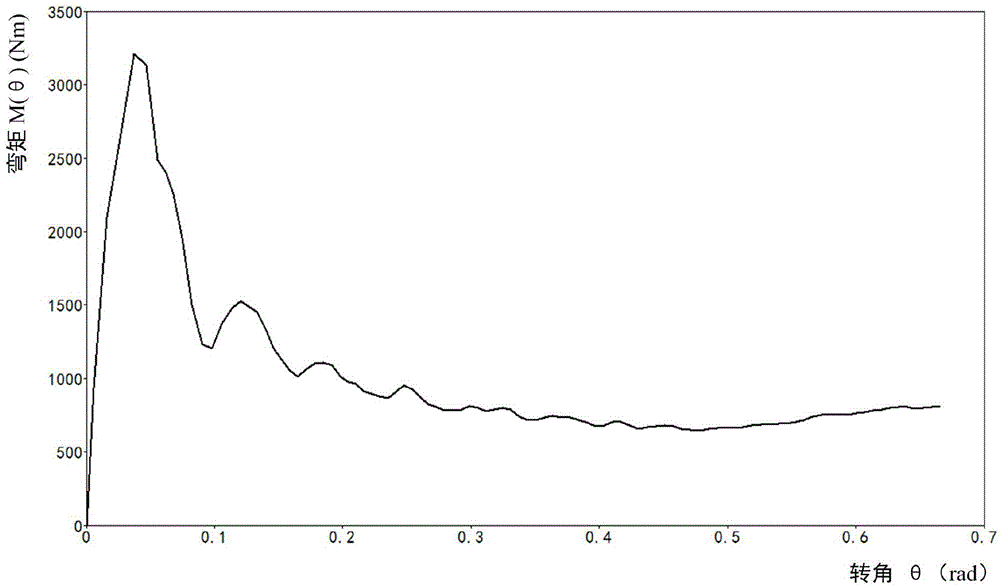

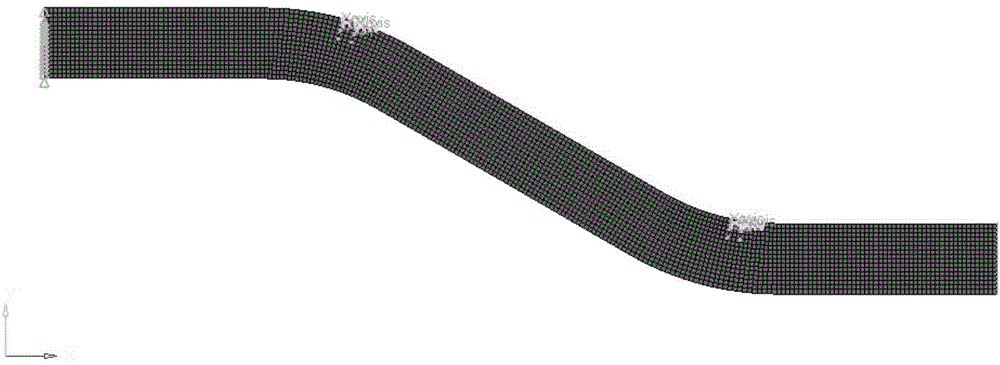

[0020] Below with the accompanying drawings and figure 1 The single hat section parameters shown in and the material parameters in Table 1 are taken as examples to further introduce the present invention. refer to figure 1 Create a 3D model in catia for the parameters of the single hat section shown in , and then import the model into hypermesh for model processing, mesh division, adding solder joints and other pre-processing work, refer to the material parameters in Table 1, and assign material properties. Boundary conditions and load cases for detailed finite element models see image 3 As shown, that is, the left end of the model is fully constrained, and a 500KG mass point is attached to the right end. The mass point moves along the negative direction of the X axis at an initial speed of 15m / s. Create control cards in hypermesh, such as controlling collision time, load step size, output parameters, hourglass control, contact control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com