Electric power overhaul ladder

A technology for electric power maintenance and maintenance ladders, which is applied in the direction of ladders, overhead lines/cable equipment, buildings, etc., which can solve the problems of reducing maintenance efficiency, increasing labor intensity of operators, and injury to operators, so as to improve construction safety and save The effect of manpower and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

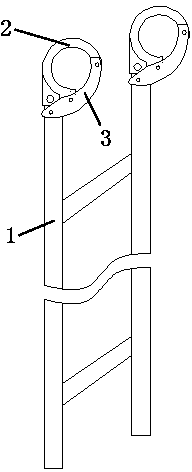

[0010] Such as figure 1 As shown, an electric maintenance ladder includes a maintenance ladder body 1, at least two fixing shackles are provided at the front end of the maintenance ladder body 1, and the fixing shackles are hingedly connected with the maintenance ladder body 1, and the fixing hooks are airtight Ring, made of fixed ring block 2 and movable ring block 3, wherein one end of the movable ring block 3 is hingedly connected with the fixed ring block 2, and the other end is connected with the fixed ring block 2 and the maintenance ladder body 1 pin, wherein the length of the movable ring block 3 is 1 / 4-1 / 3 of the fixed ring block 2 lengths.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com