Gas turbine engine comprising three rotary bodies

A technology for gas turbines and engines, applied in gas turbine installations, engine components, machines/engines, etc., can solve the problems of heavy engine weight, limit fuel saving, etc., and achieve the effect of weight and size optimization, length and weight reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

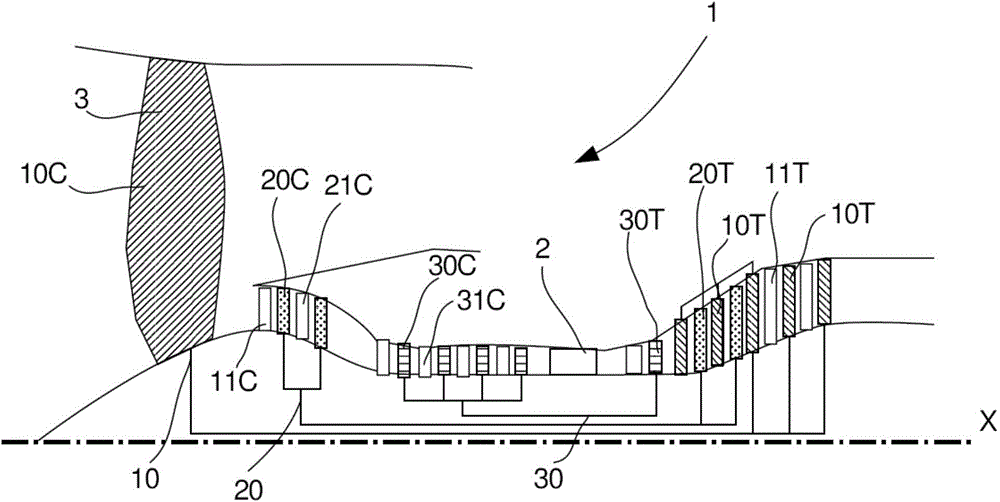

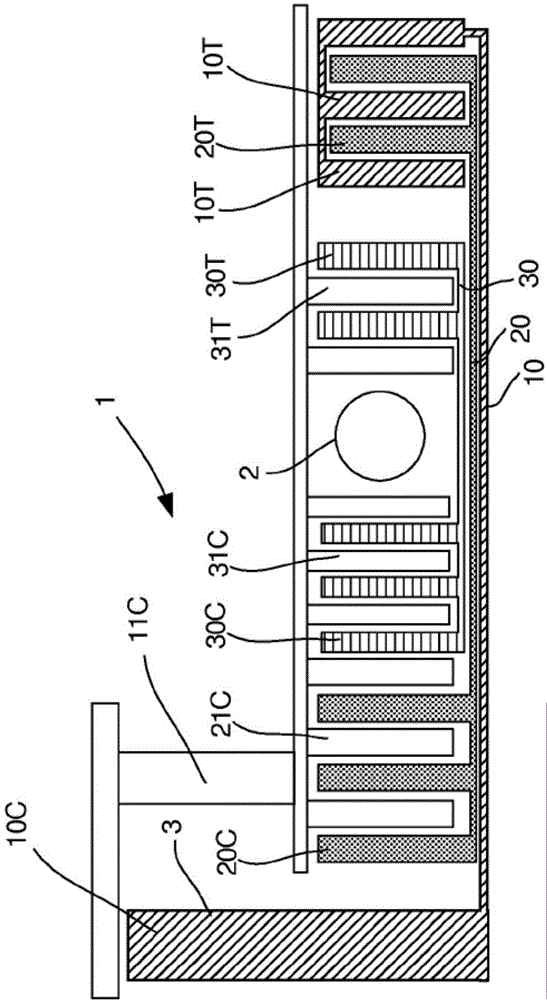

[0027] It should be noted that these drawings illustrate the invention in detail for the purpose of carrying it out, but, obviously, said drawings can be used to better define the invention if necessary.

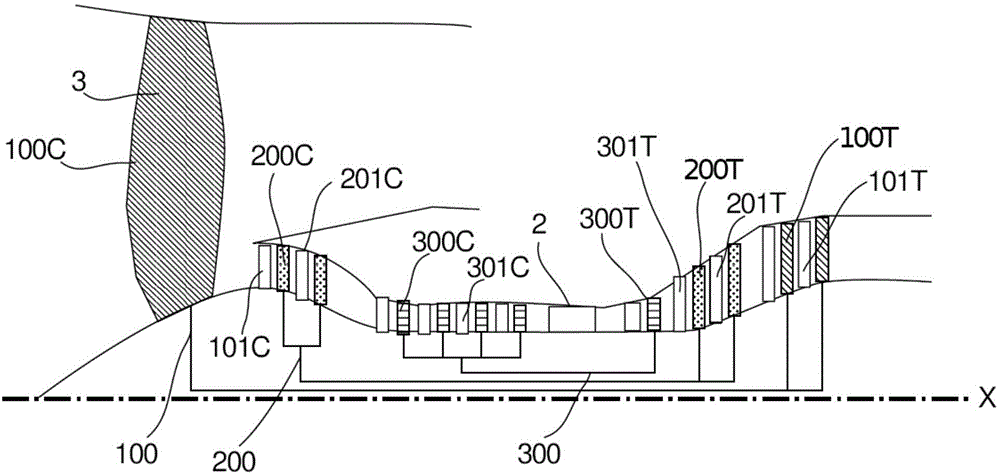

[0028] like figure 2 As shown, a turboshaft engine 1 of axis X comprises a plurality of compressor stages axially compressing the gas flow from upstream to downstream, a combustion chamber 2 and a plurality of turbine stages for recovering combustion energy. The turboshaft engine 1 includes a low-pressure rotary body 10 , an intermediate rotary body 20 and a high-pressure rotary body 30 , including compressor rotor blades 10C, 20C, 30C and turbine rotor blades 10T, 20T, 30T, respectively. In the middle of the low pressure compressor blades 10C, the turbo compressor 1 comprises upstream large fan blades 3 . Each mandrel consists of a shaft on which are mounted radially the compressor rotor blades and the turbine rotor blades. Thus, the turbine rotor blades and the compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com