Solvent oil fractionating tower pressure stability control and tail gas utilization device

A voltage stabilization control and fractionation column technology, applied in the direction of distillation adjustment/control, can solve problems such as increased energy consumption, unfavorable fractionation control, impact on fractionation efficiency and product quality control, and achieve easy operation and control, product quality, and The effect of making full use of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

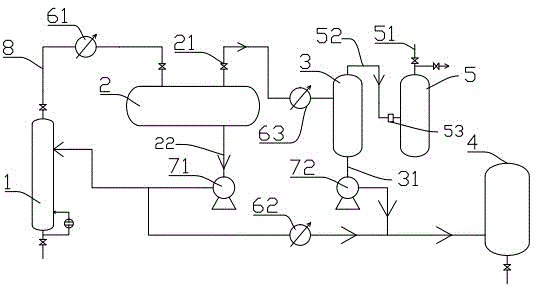

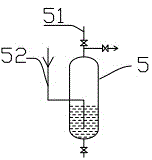

[0011] With reference to the accompanying drawings, the solvent oil fractionation tower pressure stabilization control and tail gas utilization device includes a fractionation tower 1, the bottom of the fractionation tower 1 is provided with a reboiler for fractionation heating, and the top of the fractionation tower 1 is connected in series with a first condenser 61 through a pipeline 8, A reflux tank 2 is connected to the rear end of the condenser. The upper and lower ends of the reflux tank 2 are respectively provided with a gas phase outlet 21 and a liquid phase outlet 22. The liquid phase outlet 22 is connected with a first delivery pump 71. A part of the output liquid of the delivery pump is refluxed to the fractionation tower 1, and the other part is condensed through the second condensate. After the device 62 cools down, it enters the storage tank. The rear end of the gas phase outlet 21 is connected with a fractionation pressure regulating device, and the fractionatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com