Profile seamless bending mold and seamless bending method

A technology of bending dies and profiles, which is applied in the field of seamless bending of profiles and seamless bending molds of profiles, which can solve problems such as stacking of ribs, gaps in splicing gaps, etc., and achieve good strength and simple and convenient processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

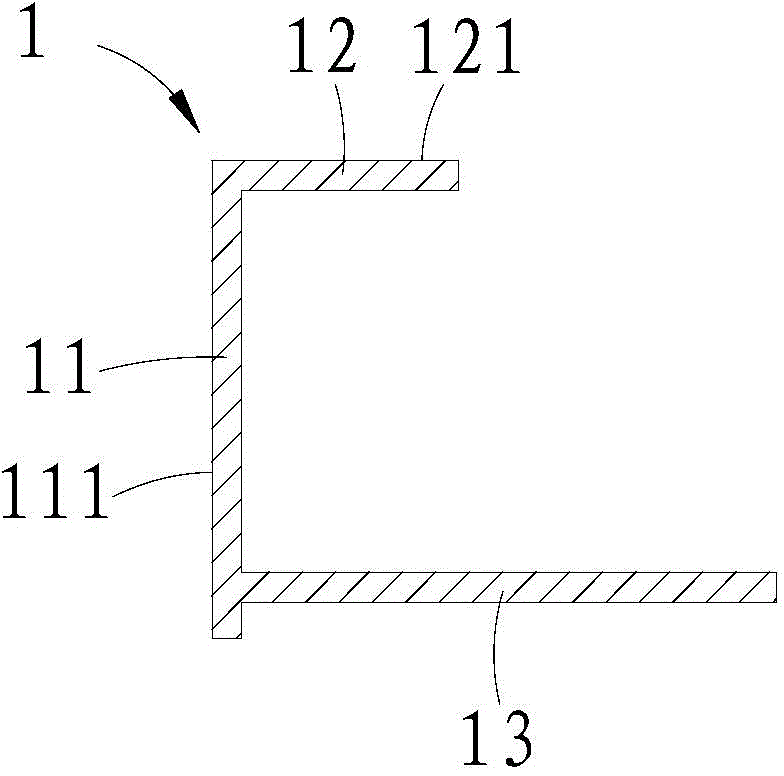

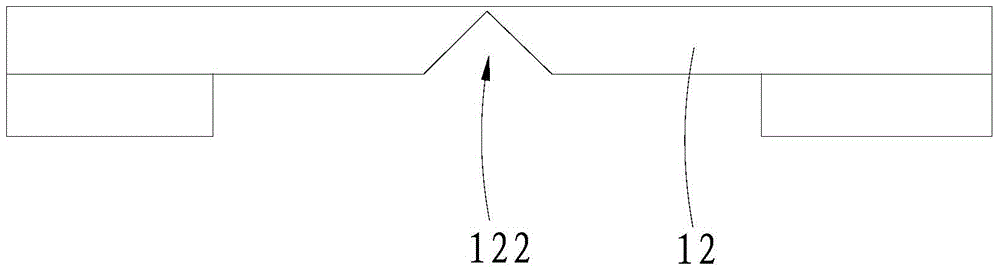

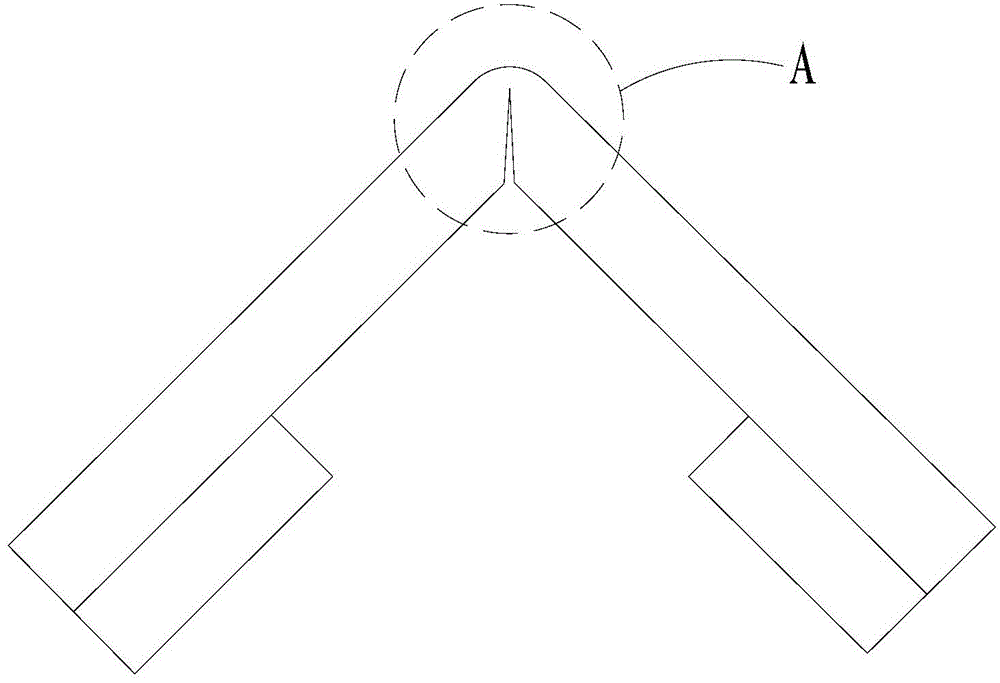

[0024] see figure 1 , Figure 5 with Figure 7 , a profile 1 seamless bending mold 2 provided by an embodiment of the present invention. The profile 1 includes a side panel 11 and a rib 12 extending perpendicular to one side of the side panel 11 . The mold 2 includes a mold base 21 , a die 22 , a punch 23 , a pressing plate 25 , a first driving mechanism (not shown) and a second driving mechanism (not shown). The mold base 21 is used for placing and positioning the profile 1 . The die 22 is installed on the die holder 21 . The convex mold 23 is installed on the mold base 21 and corresponds t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap