Pitch shaper for hot coiled spring

A technology of hot coil spring and shaper, which is applied in the direction of making springs, other household appliances, household appliances, etc. from wires, can solve the problems of easy damage to the surface of the spring, long time for dressing, affecting the quality of the spring, etc., so as not to damage the surface of the spring. , The effect of improving the efficiency of the whole spring and the high efficiency of the whole spring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

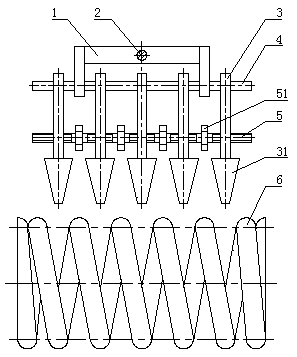

[0007] see figure 1 , the present invention comprises a fixed frame 1, a handle 2, five horizontally distributed plastic knives 3, a bearing rod 4 and a screw shaft 5, the lower end of each of the plastic knives 3 is provided with a cutter head 31, and the screw shaft 5 There are five sections of threads set at intervals from left to right in the order of left-handed threads and right-handed threads. Bolt heads 51 are arranged in the middle of every two adjacent sections of threads on the screw shaft 5. The bearing rod 4 is formed by Made of square steel, the bearing bar 4 is connected to the fixed frame 1 by welding, the upper part of each shaping knife 3 is provided with a square hole, and can slide horizontally along the bearing bar 4, and each shaping knife 3 and The screw shaft 5 is threaded. The cutter head 31 is in the shape of an inverted cone.

[0008] When trimming the spring 6, first rotate the screw shaft 5 by rotating the bolt head 51, adjust each cutter head 31...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com