Bamboo chip squeezing and setting-out machine

A technology of flattening and bamboo chips, applied in wood processing appliances, bark areas/debris/dust/waste removal, manufacturing tools, etc., can solve the problems of reducing the rolling effect of moso bamboo chips, losing rolling flatness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to describe in detail the technical content, structural features, achieved objectives and effects of the present invention, the following is a detailed description in conjunction with the embodiments and accompanying drawings.

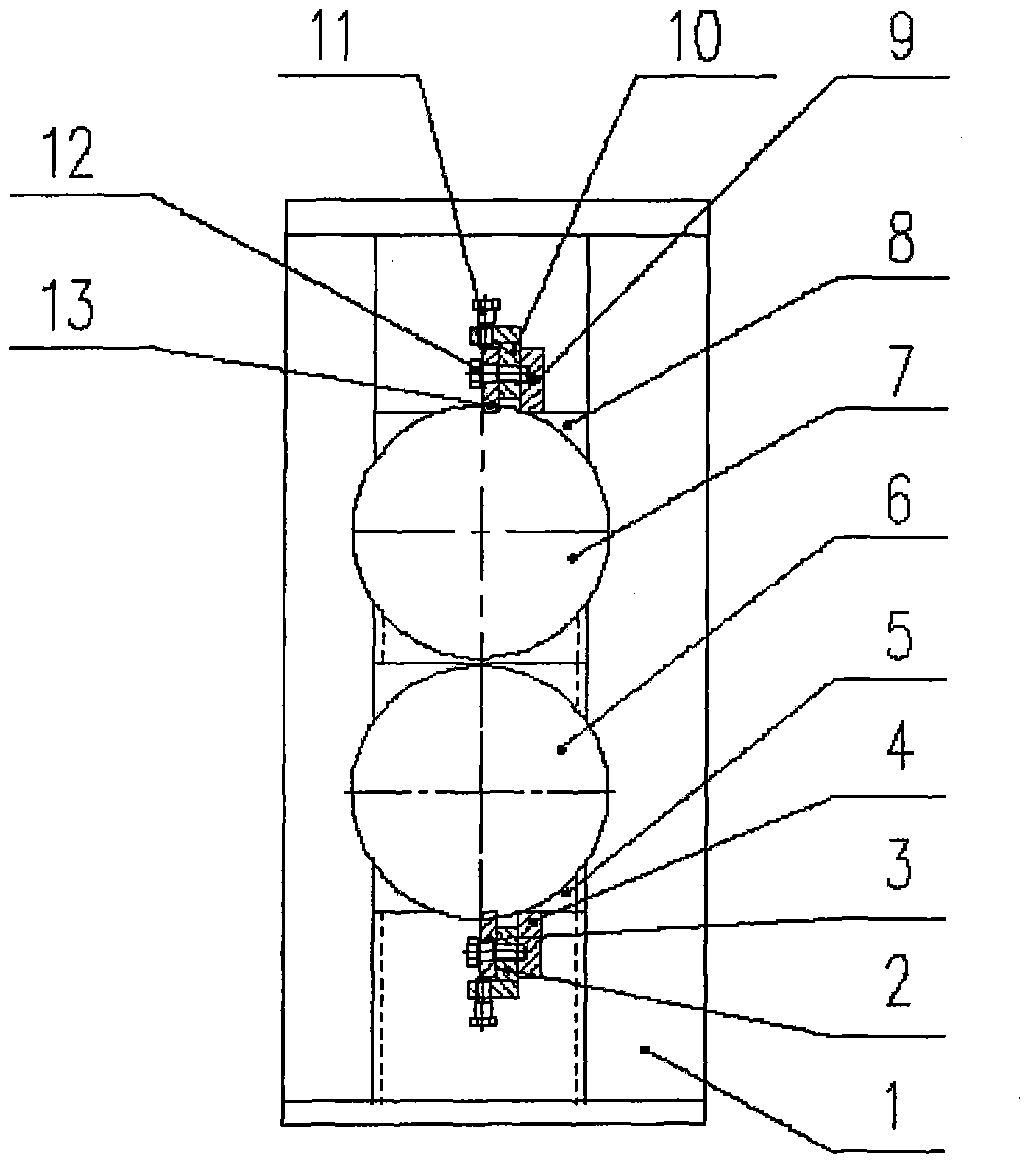

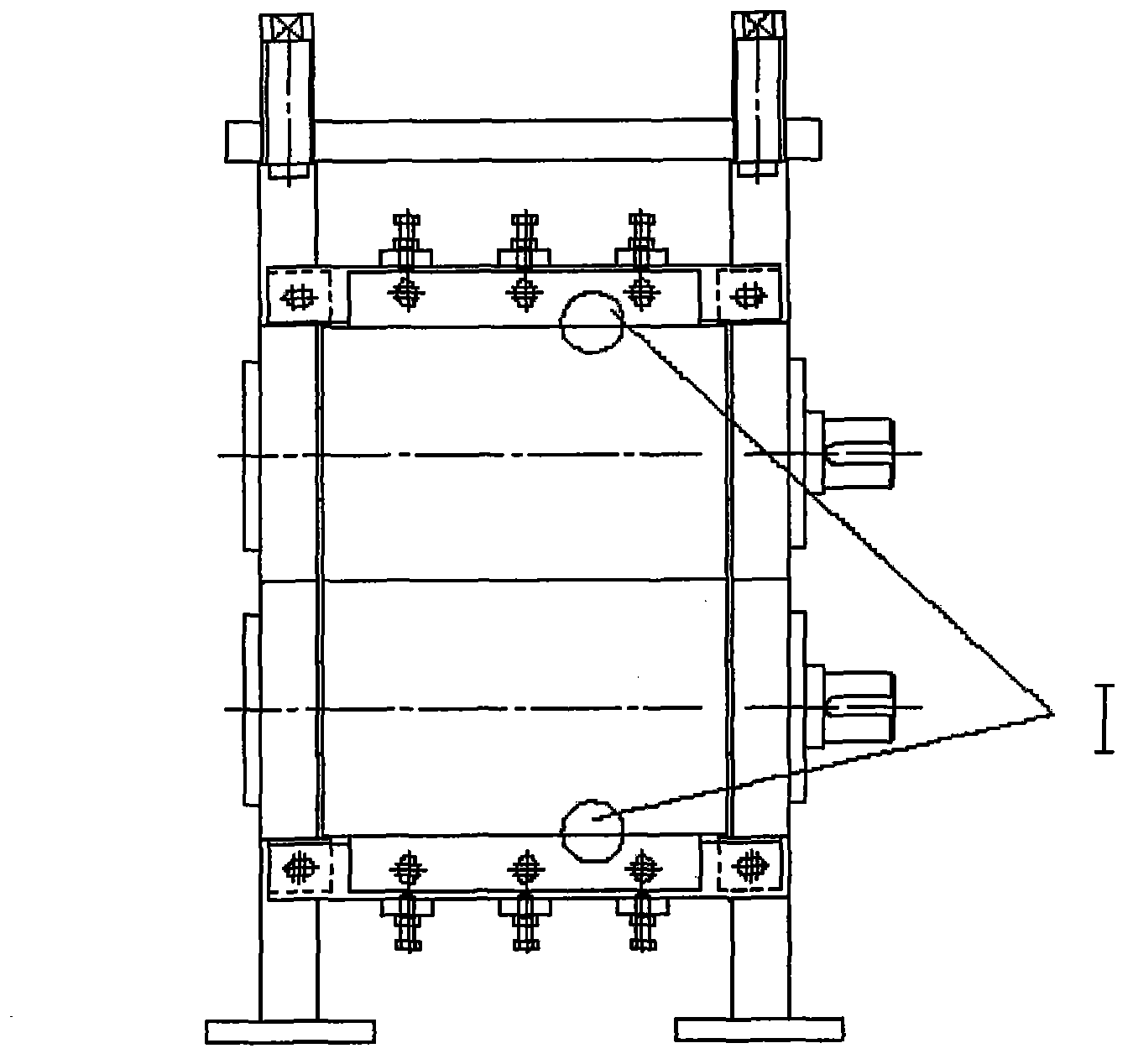

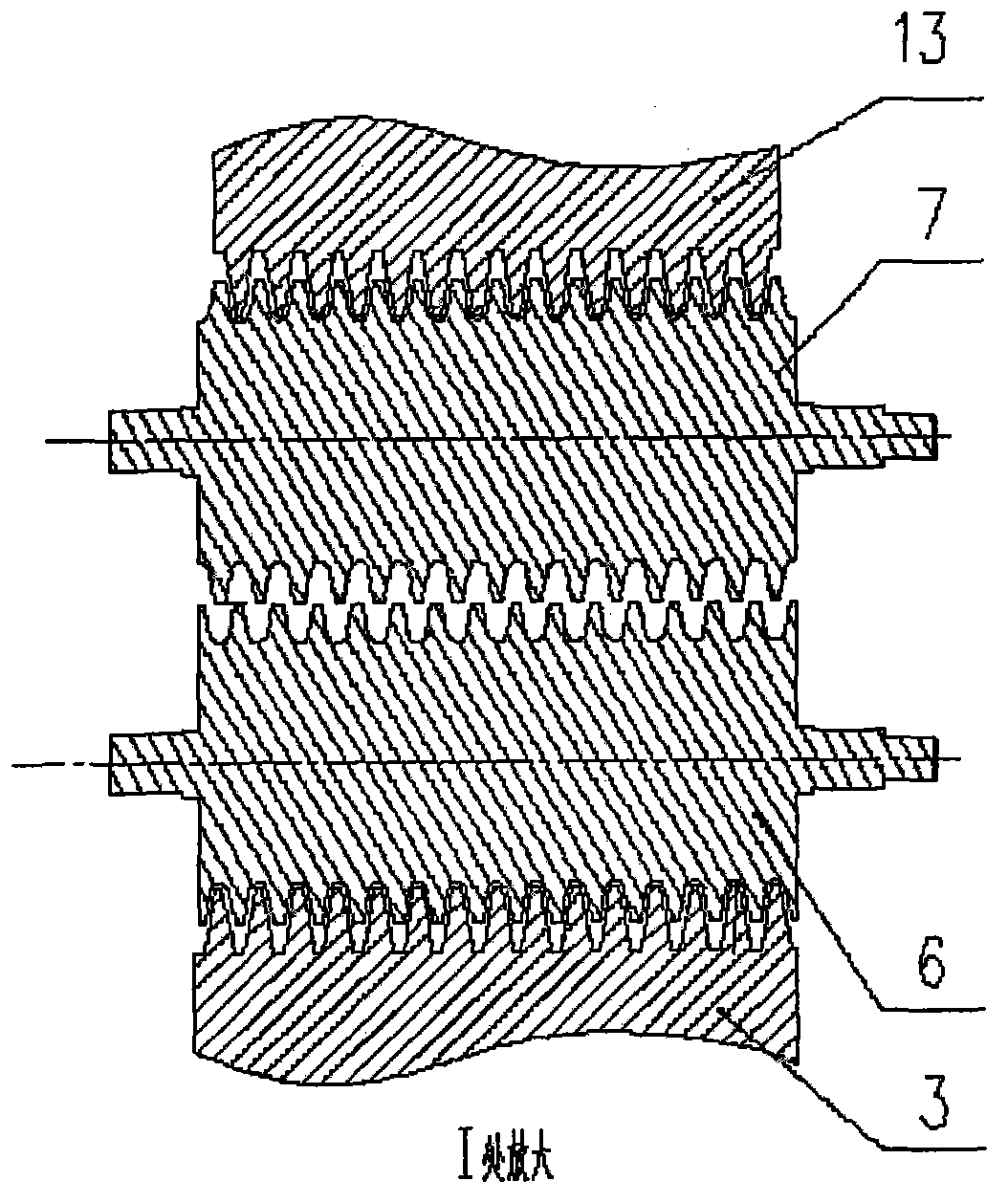

[0017] Reference figure 2 As shown, the bamboo sheet squeezing and flattening machine of the present invention includes a frame 1. The frame 1 is equipped with multiple sets of upper rollers 7 and lower rollers 6, and the upper roller assembly includes upper rollers. The pressure roller 7, the upper sliding seat 8 and the upper sparse plate assembly, the lower rolling roller assembly includes a lower rolling roller 6, a lower seat 5 and a lower sparse plate assembly, the upper sparse plate assembly includes an upper sparse plate 13, an upper The sparse slab fixed cross beam 10 and the upper sparse slab fixed cross beam seat 9. The lower sparse slab assembly includes an upper sparse slab 3, a lower upper sparse slab fixed cross beam 5, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com