An electromagnetic mounting device for aerial bombs

An aerial bomb and mounting technology, which is applied in transportation and packaging, military equipment configuration, aircraft parts, etc., can solve the problems of large aircraft interior space, occupancy, increase radar reflection cross-sectional area, etc., and achieve the goal of reducing aerodynamic and stability performance Influence, simplification of the mounting and delivery structure, and the effect of reducing the reflection cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

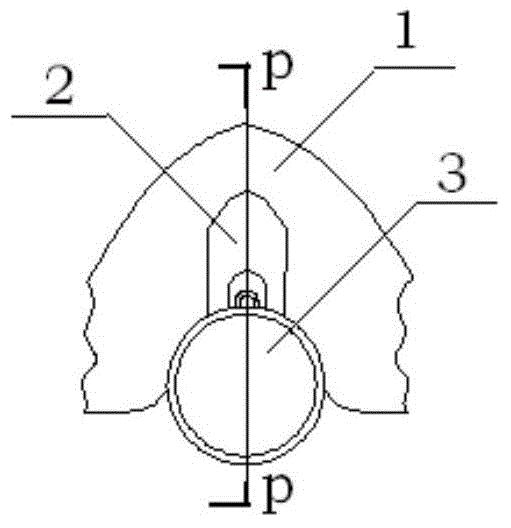

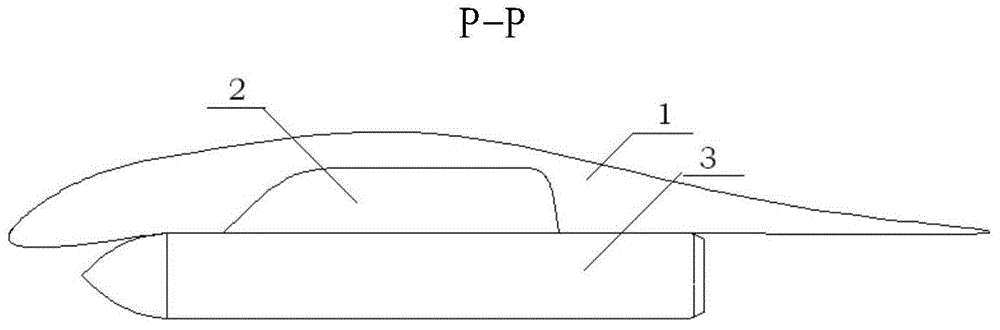

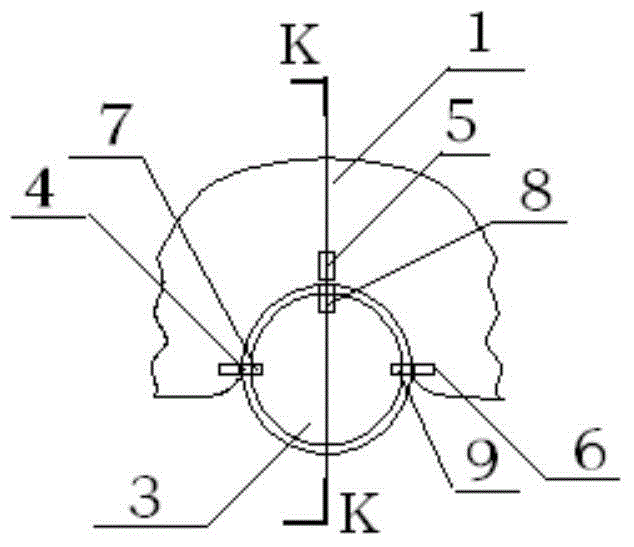

[0010] The present invention will be described in further detail below. see image 3 , 4 , an electromagnetic mounting device for aerial bombs, comprising a wing 1 of a carrier aircraft and a mounted aerial bomb 3, a semi-buried bomb bay is arranged on the lower surface of the wing 1, and the aerial bomb 3 passes through the mounting device Mounted in the semi-buried bomb bay; it is characterized in that: there are two sets of embedded bomb electromagnets on the bomb 3, and each group of bomb electromagnets consists of the first bomb electromagnet 7 and the second bomb electromagnet. The bomb electromagnet 8 and the third bomb electromagnet 9 are composed, two groups of bomb electromagnets are arranged forward and backward along the axis of the bomb 3, and the first bomb electromagnet 7 to the third bomb electromagnet 9 are arranged along the semicircle of the bomb 3 Evenly distributed around the week; there are two groups of bomb electromagnets on the inner surface of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com