Cover to prevent contents from sticking

A content and anti-adhesion technology, applied in the direction of closure, packaging, layered products, etc., can solve the problems of poor surface hydrophobicity and easy deterioration, to maintain fixity, prevent the reduction of anti-adhesion performance, and avoid adhesion Insufficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

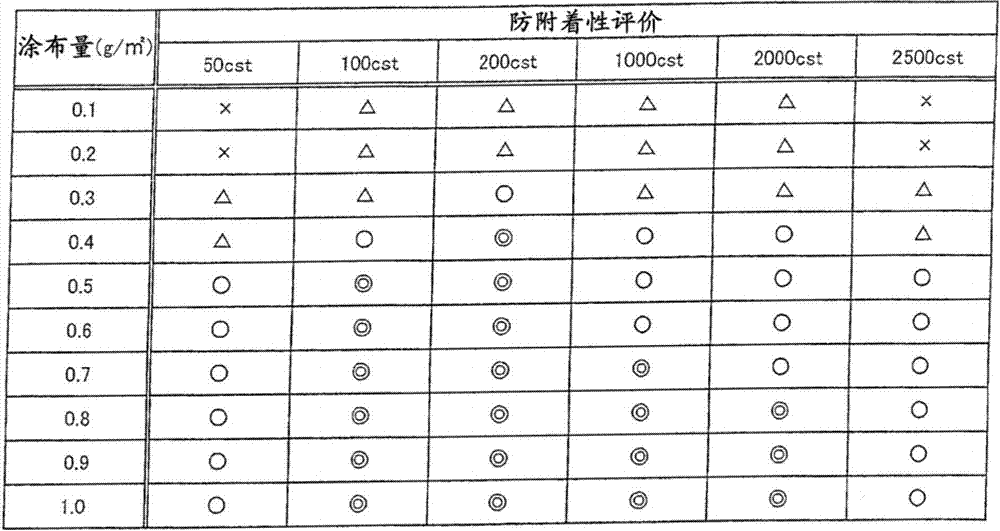

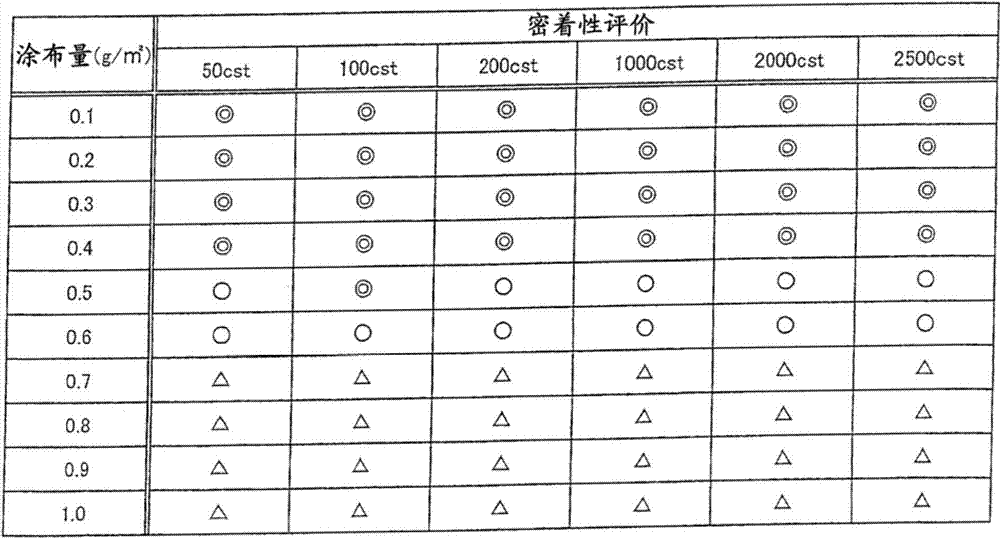

[0129] [Example of the first invention]

[0130] Next, various experimental examples and results thereof are shown to confirm the effects of the first invention.

[0131] (manufacturing of the main body of the cover)

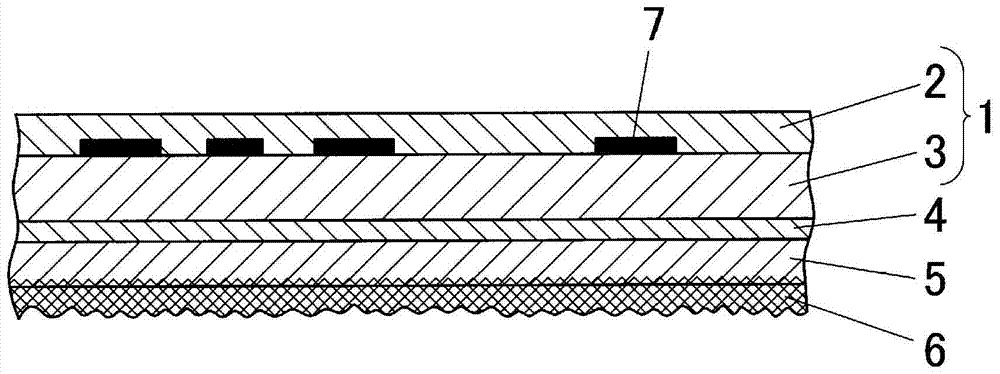

[0132] As the base film (2), a polyethylene terephthalate film with a thickness of 12 μm is used, and an aluminum foil (3) with a thickness of 30 μm is bonded to one side of the film with a polyurethane dry lamination adhesive to form a substrate. material layer (1).

[0133] Next, on the surface of the aluminum foil (3) side of the above-mentioned base material layer (1), a polyethylene film with a thickness of 20 μm is laminated and bonded with the same adhesive as above to form an intermediate resin layer (4), and further on the outside, The heat-seal layer (5) was formed by gravure coating. The thus-obtained laminate of base material layer ( 1 ) / intermediate resin layer ( 4 ) / heat seal layer ( 5 ) was used as a cover body. Here, as the heat-sealing layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com