New telescopic fork

A telescopic fork, a new type of technology, applied in the direction of lifting devices, etc., can solve problems such as accidents, cargo slipping, complicated operation, etc., and achieve the effect of not easy to collide, large load capacity, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

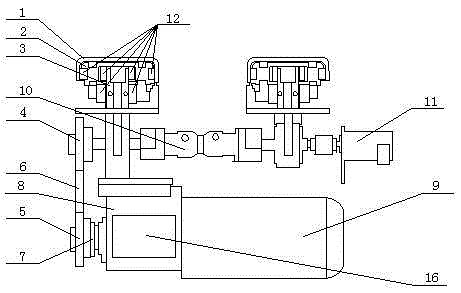

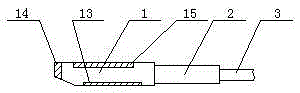

[0009] see Figure 1-2 , the specific embodiment adopts the following technical scheme: it includes the upper fork 1, the middle fork 2, the lower fork 3, the first gear 4, the second gear 5, the chain 6, the clutch 7, the driving device 8, the motor 9, the cardan shaft 10. Rotary encoder 11, bearing 12, the middle fork 2 is set on the inner side of the upper fork 1, several bearings 12 are respectively set on the inner sides of the upper fork 1, the bearings 12 are set in the groove of the middle fork 2, the middle fork 2 The lower fork 3 is arranged on the inner side of the lower fork 3, and several bearings 12 are arranged on both sides of the lower fork 3. The upper fork 1, the middle fork 2, and the lower fork 3 form the first telescopic device, and the first telescopic device is fixed on the driving device 8 through the support seat. Above, the right side of the driving device 8 is connected with the motor 9, the left side of the driving device 8 is connected with the cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com