Upper disk and lower disk knitting mechanism for double-sided automatic underwear machine

An underwear machine, automatic technology, applied in the direction of weft knitting, knitting, textiles and papermaking, etc., can solve the problems of affecting production efficiency and poor effect, and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

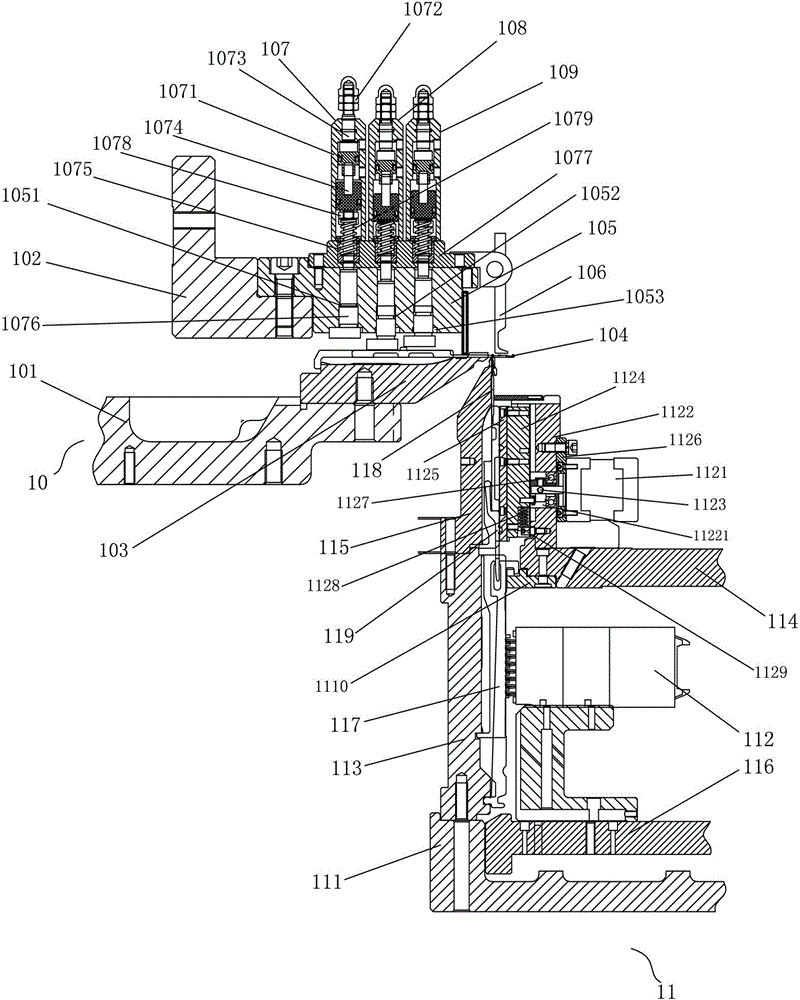

[0013] Such as figure 1 As shown, a double-sided automatic underwear machine upper and lower disc knitting mechanism includes an upper disc knitting mechanism 10 and a lower disc knitting mechanism 11; the upper disc knitting mechanism 10 includes a dial base 101 and a cutting disc base 102. Located below the cutting disc base 102; the dial base 101 is connected with a dial 103, and the dial 103 is connected with several upper needles 104 with high and low stitches; the cutting disc base 102 is connected with a cutting disc 105 The cutting disc 105 is located above the dial 103; the right end of the cutting disc 105 is connected with a yarn feeder 106; the tongue-opening end of the yarn feeder 106 is connected with the latch of the upper needle 104 with high and low stitches; The cutting disk 105 is connected with a cylinder needle selection device; the cutting disk 105 is provided with a first needle selection groove 1051, a second needle selection groove 1052, and a third ne...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap