Cast-in-situ pile casing and its construction method

A construction method and technology of cast-in-place piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of affecting the quality of the pile body, high resistance of pile sinking, and difficulty of sinking piles, so as to reduce the effect of soil squeezing and pile sinking The effect of small resistance and easy hole formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

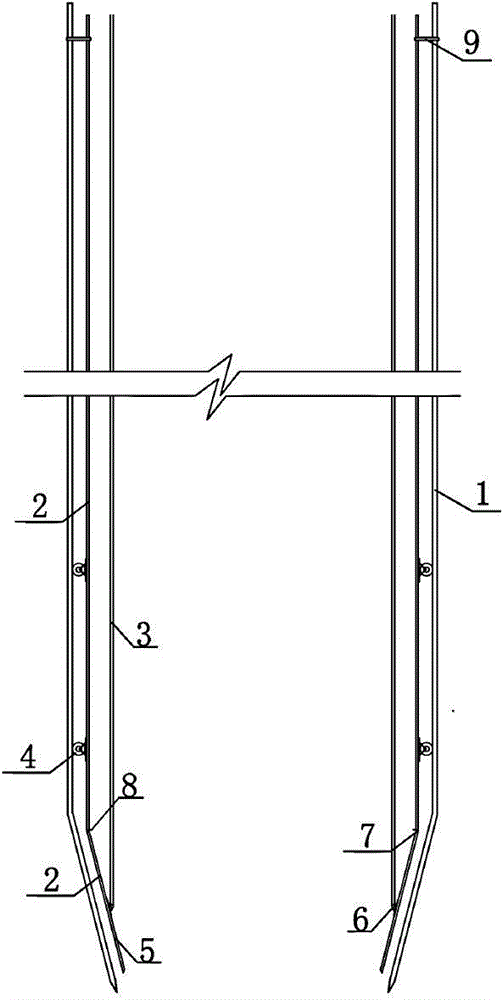

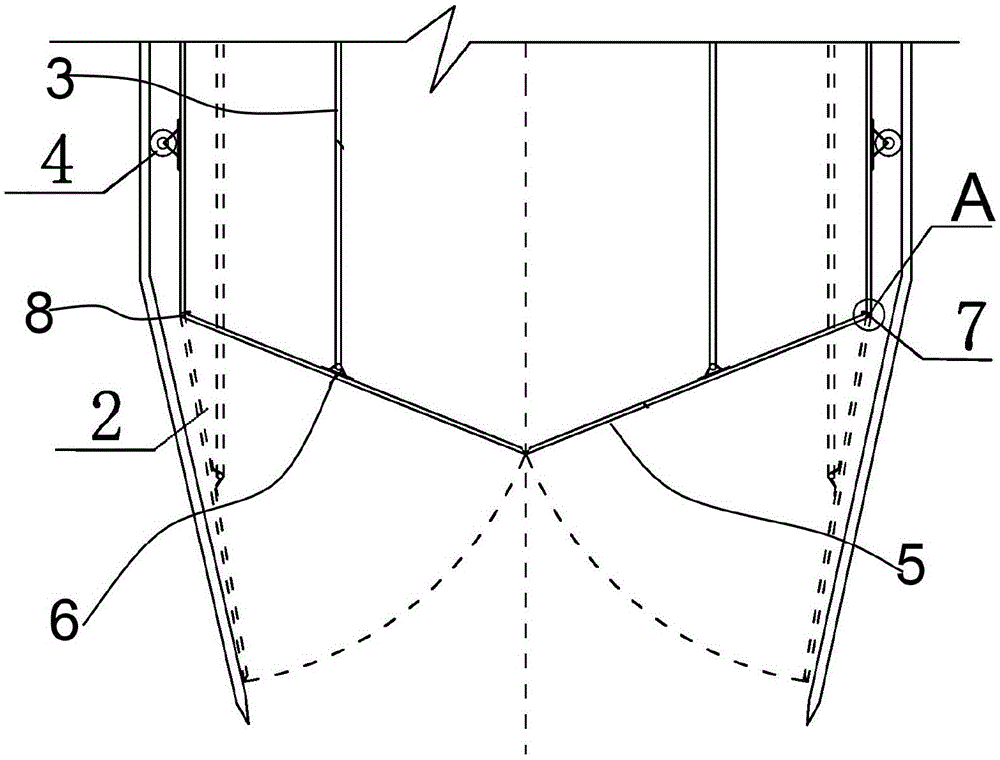

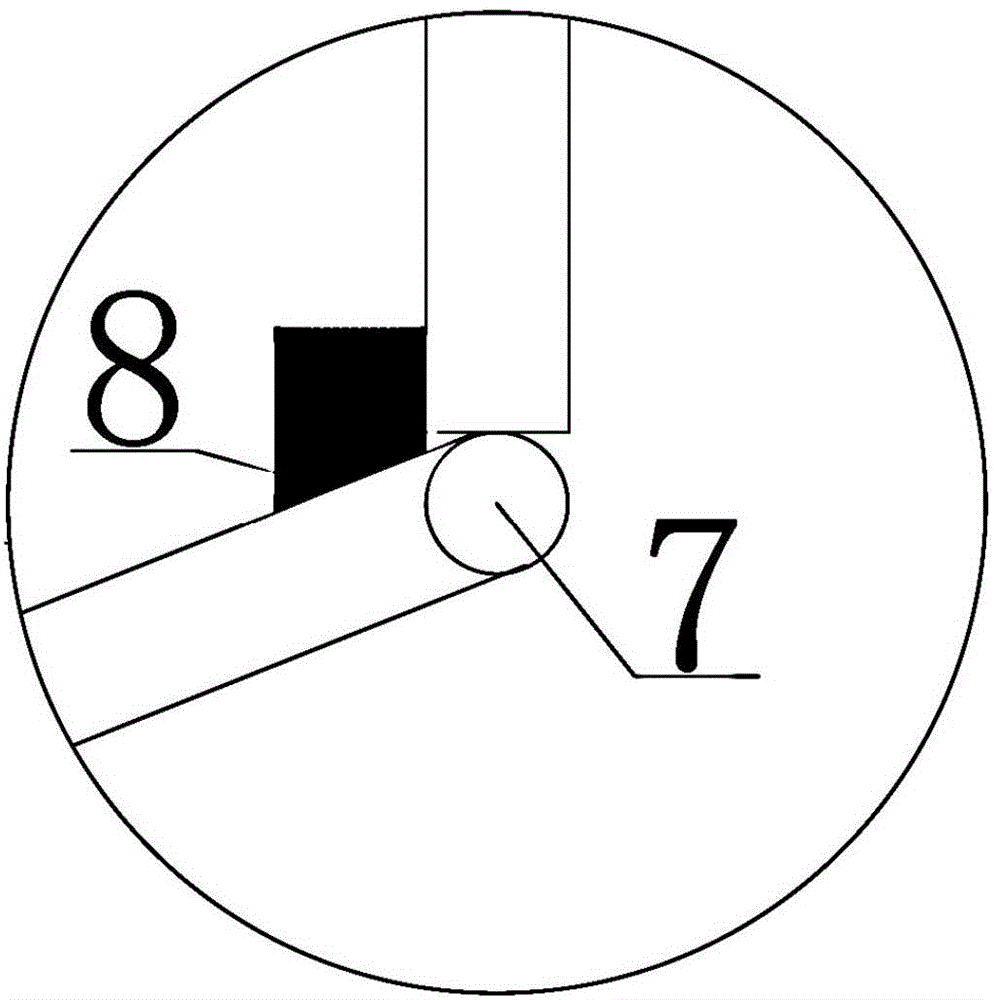

[0018] Such as Figure 1 to Figure 6 As shown, the cast-in-place pile casing 5 of the present invention includes a first tubular body 1 with a hollow interior and openings at both ends, a second tubular body 2 sleeved in the first tubular body 1, and rotatably connected to the lower end of the second tubular body 2 The petal 5, and one end is movably connected to the petal 5 through the first hinge 6, and the other end extends out of the rope body 3 from the upper end of the second tubular body 2. Among them, the petals are multi-petal petals, which are shaped as steel sheets with a certain arc shape, which can completely seal the lower end of the inner casing. The specific shape is determined according to parameters such as the diameter of the inner casing and the inclination angle of the lower end of the casing. It can be rotatably coupled with the second pipe body through, for example, the second hinge 7 .

[0019] The above-mentioned pile casing is composed of an inner ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com