Construction method of building ceramic thin plate hanging structure

A technology of architectural ceramics and construction methods, applied in building construction, construction, covering/lining, etc., can solve problems such as high cost, unsuitable energy conservation and environmental protection, pollution, etc., and achieve low cost, improved utilization rate, and low space occupancy rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

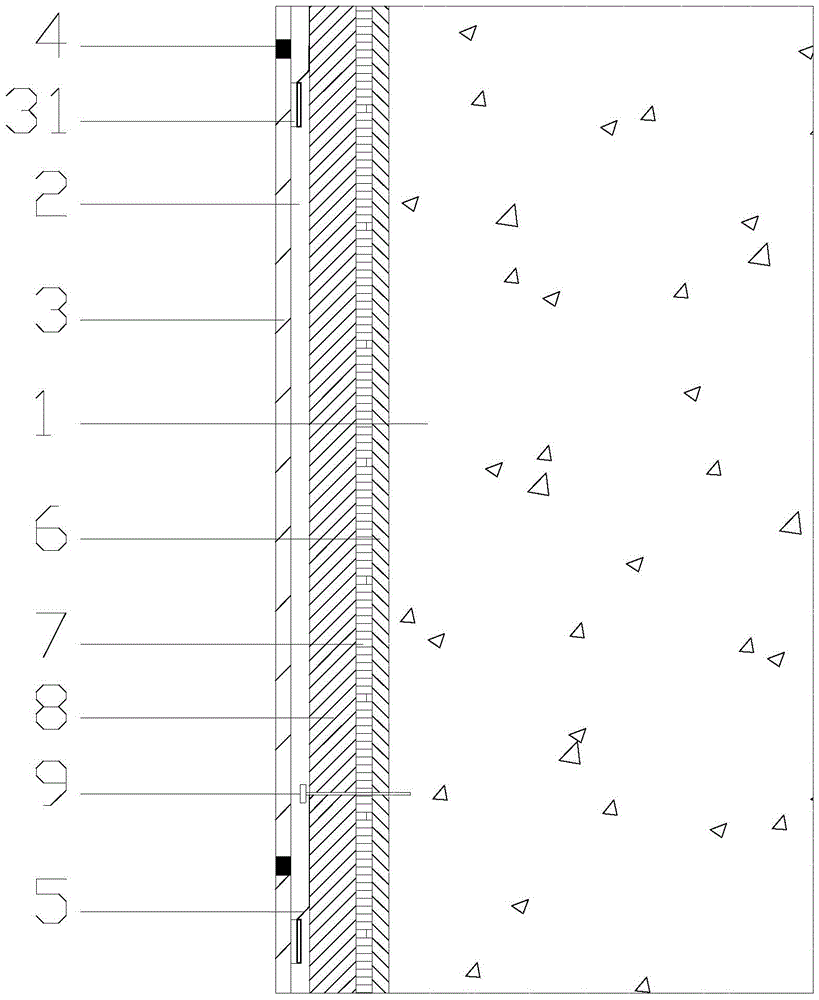

[0039] Such as figure 1 As shown, the building ceramic sheet hanging paste structure includes a wall 1, an adhesive 2, a building ceramic sheet 3, a pendant 31, a peg 9 and a connector 5;

[0040] The building ceramic sheet 3 is bonded to the wall 1 using the adhesive 2;

[0041] A caulking agent 4 is provided between the building ceramic sheets 3;

[0042] The pendant 31 is fixed on the back of the thin building ceramic plate 3, the peg 9 is located above the thin building ceramic plate 3 and embedded in the wall 1, the pendant 31 and the peg 9 are formed by the The connecting piece 5 is connected.

[0043] Further, the pendant 31 is a stainless steel sheet with holes, the pendant 31 is fixed on the back of the building ceramic sheet 3 by epoxy adhesive 2, the size of the sticking surface is gre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com