Pilot large-flow load control valve using displacement and force feedback principle

A technology of load control and force feedback, which is applied in the direction of fluid pressure actuators, servo motor components, mechanical equipment, etc., can solve the problems of load speed jitter, large stability margin of the main valve core, poor load speed control effect, etc., to achieve Stable load speed control, improved stability, and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

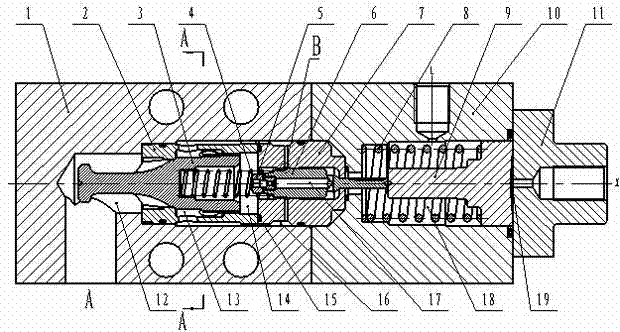

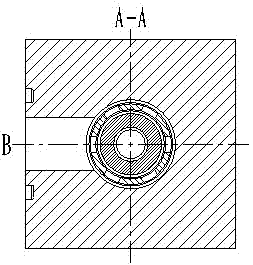

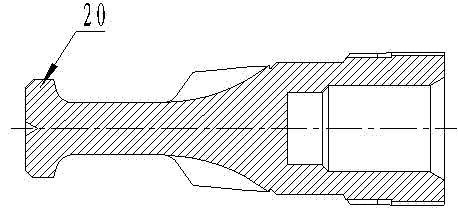

[0022] Such as figure 1 As shown, the present invention includes a main valve body 1, a main valve sleeve 2, a main valve core 3, a feedback spring 4, a load pressure compensation damper 5, a pilot valve core 6, a pilot valve sleeve 7, a control spring 8, a control piston 9 and a pilot Valve body 10 and end cover 11.

[0023] Such as figure 1 As shown, the main valve sleeve 2 is installed in the cylindrical hole of the main valve body 1, the oil return cavity 12 is formed between the bottom of the main valve sleeve 2 and the hole of the main valve body 1, and the small end of the main valve core 3 passes through the main valve sleeve 2 and is located at In the oil return chamber 12, the large end of the main valve core 3 is in sliding fit with the inner hole of the main valve sleeve 2, one end of the pilot valve sleeve 7 is installed in the cylindrical hole of the mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com