Homogenisation device, heat exchanger assembly and method of homogenising a temperature distribution in a fluid stream

A technology for homogenizing equipment and heat exchangers, which is applied in the field of heat exchanger components and the temperature distribution in the homogenizing fluid flow, can solve problems such as hindering and affecting the accuracy of induction temperature measurement, and achieves low pressure loss and improved accuracy. Effects of Sexuality and Reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

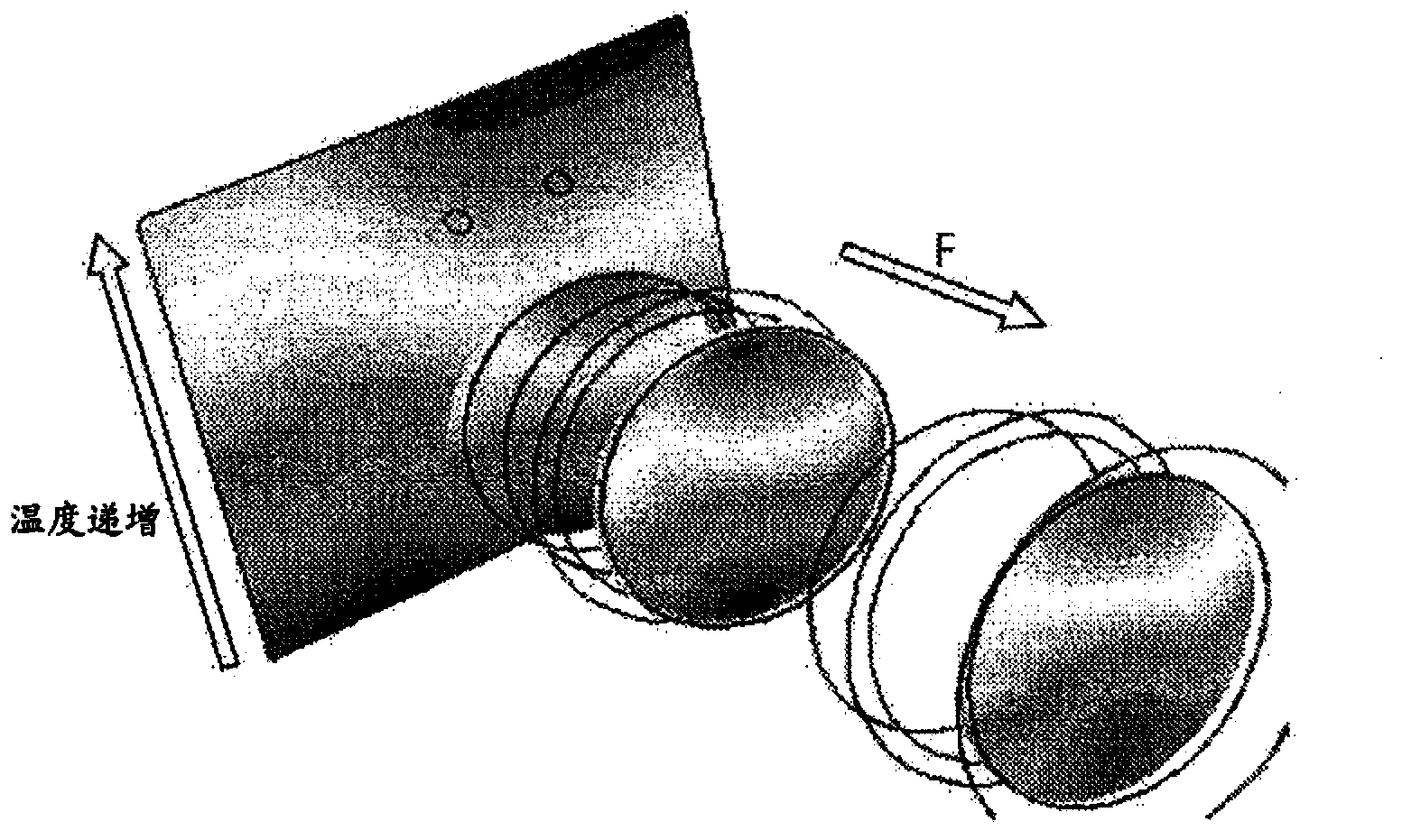

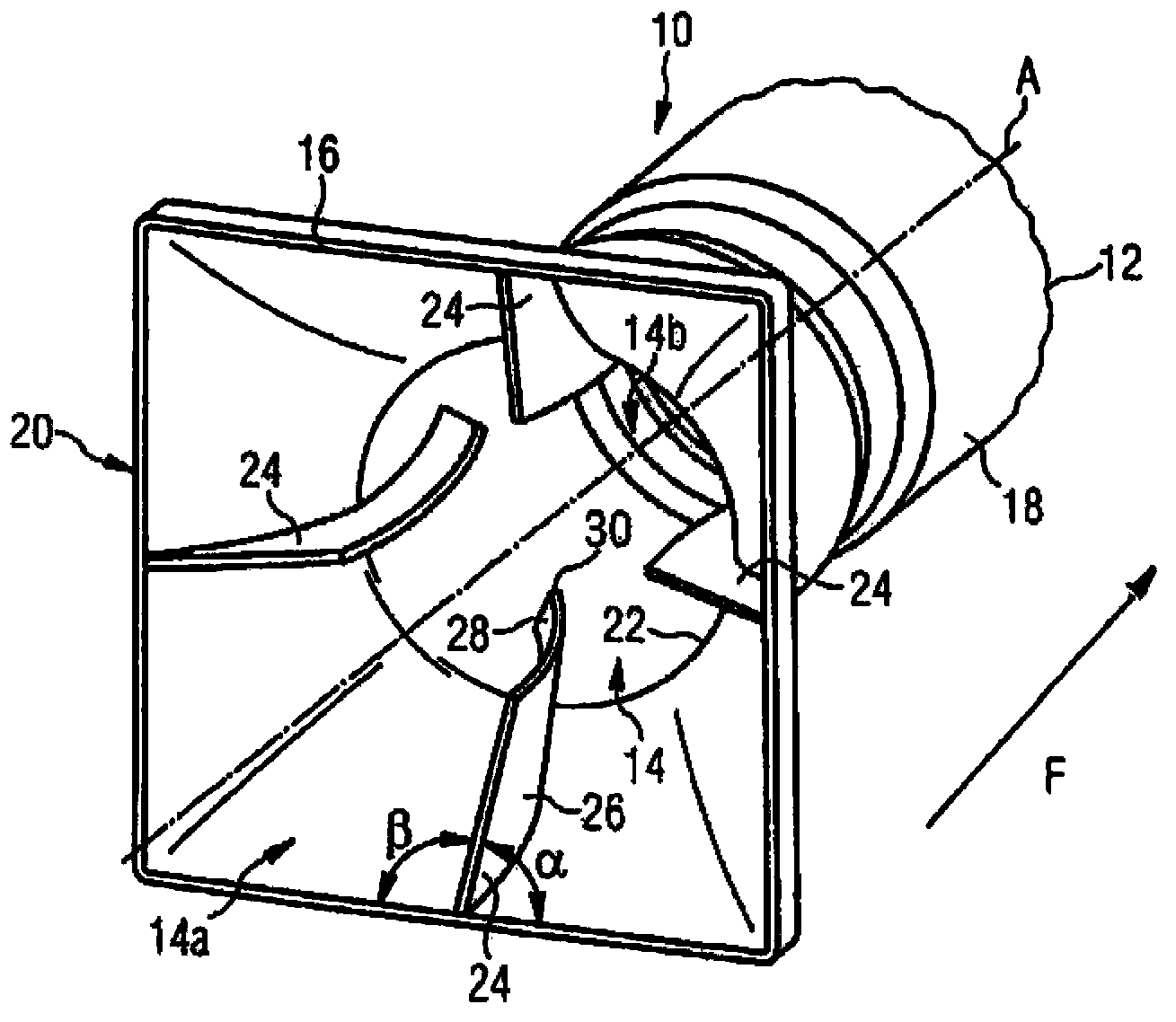

[0036] figure 1 Shown is the temperature distribution in a fluid stream leaving a heat exchanger installed on an aircraft. Depend on figure 1 It becomes apparent that the fluid flow exhibits a side-to-side temperature gradient at the outlet face of the heat exchanger, wherein when the fluid flow leaves a header of the heat exchanger having a first flow cross-section and enters a This temperature gradient is substantially maintained for tubes extending downstream and having a second flow cross-section smaller than the first flow cross-section of the heat exchanger header. In the fluid flow, the cold flow is mainly present in the lower part of the heat exchanger headers and in the lower part of the tubes extending downstream of the heat exchanger. In contrast to this, the warm current is mainly present in the heat exchanger headers and in the upper part of the tubes extending downstream of the heat exchanger. The central region of the fluid flow shows intermediate temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com