Method for rapidly representing activity of catalytic cracking catalyst

A catalytic cracking and catalyst technology, which is applied in the preparation of test samples, measuring devices, instruments, etc., can solve the problems that the catalyst activity value cannot be truly and accurately measured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

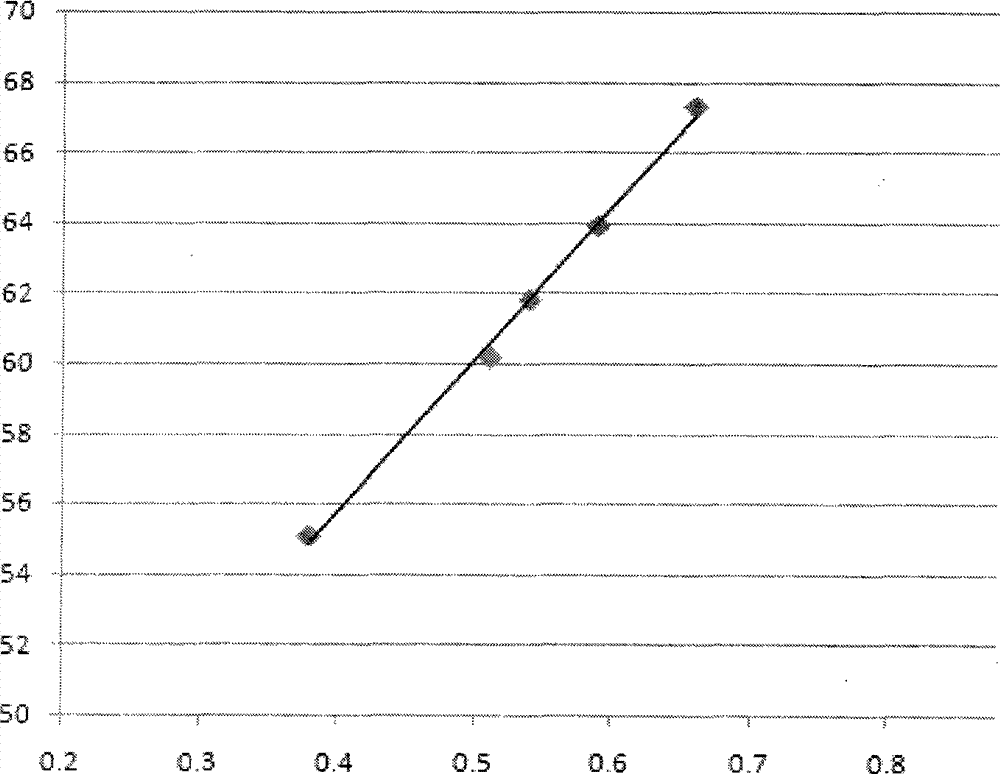

Image

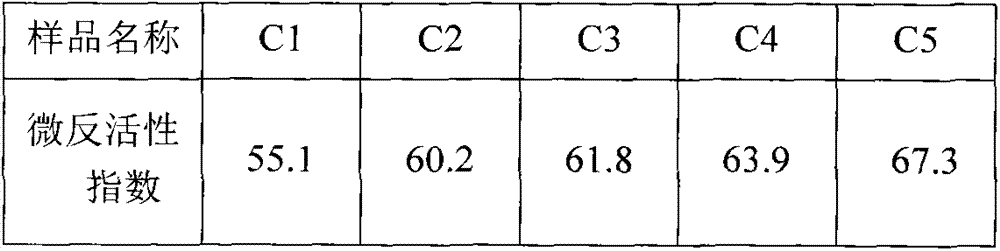

Examples

Embodiment 1

[0039] (1) Measure the value of the sample:

[0040] a. Selection of sample catalyst:

[0041] Select the balancer as the sample catalyst, the total amount of metals (Fe, Ni, V, Ca, Na) is between 10000-40000ppm, and the specific surface area is greater than 1100m 2 / g, the apparent bulk density is between 0.79-0.85g / mL.

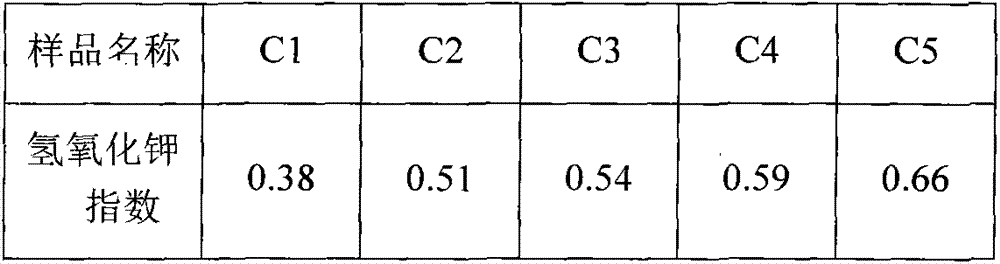

[0042] b. Determination of sample potassium hydroxide index:

[0043]Weigh five sample catalysts Ci, where i is a positive number; pour them into an evaporating dish, bake them in a high-temperature resistance furnace at 650°C for 1 hour, take them out and cool them in air for 5 minutes, then cool them to room temperature in a desiccator, and weigh After cooling, put 2.0-2.5g of the sample into a 250ml conical flask with stopper, inject 100ml of potassium hydroxide solution of known concentration into the conical flask containing the sample with a pipette, shake the conical flask for 3 minutes, and let it stand for 1 minute. Then tilt the bottle, turn the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com