Camera lens mechanism, camera lens cover and camera lens set with camera lens mechanism and camera lens cover

A lens cover and lens group technology, applied in the field of lens groups, can solve the problems of missing the opportunity to capture beautiful scenery, unable to turn on the machine and press the shutter immediately, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

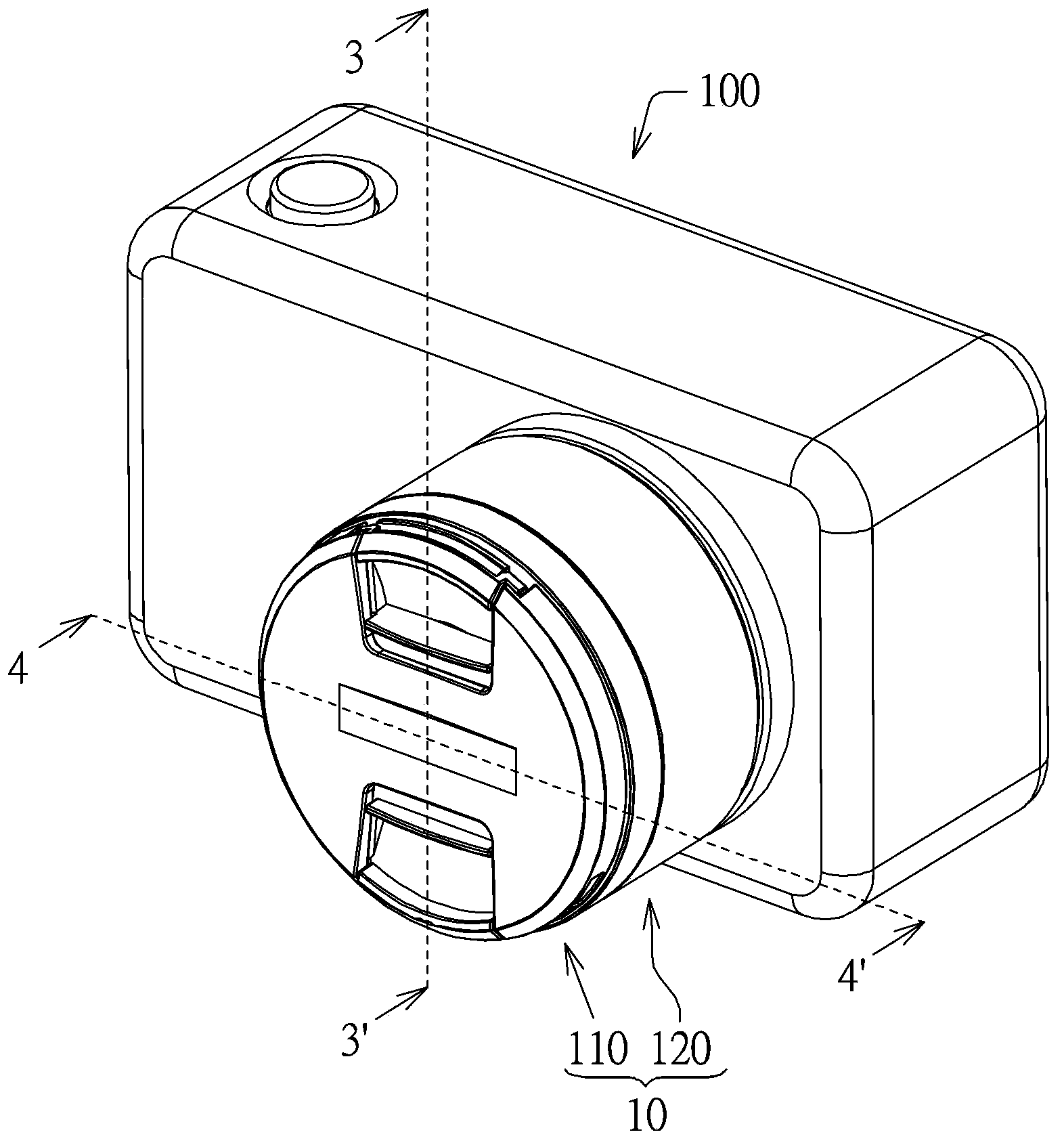

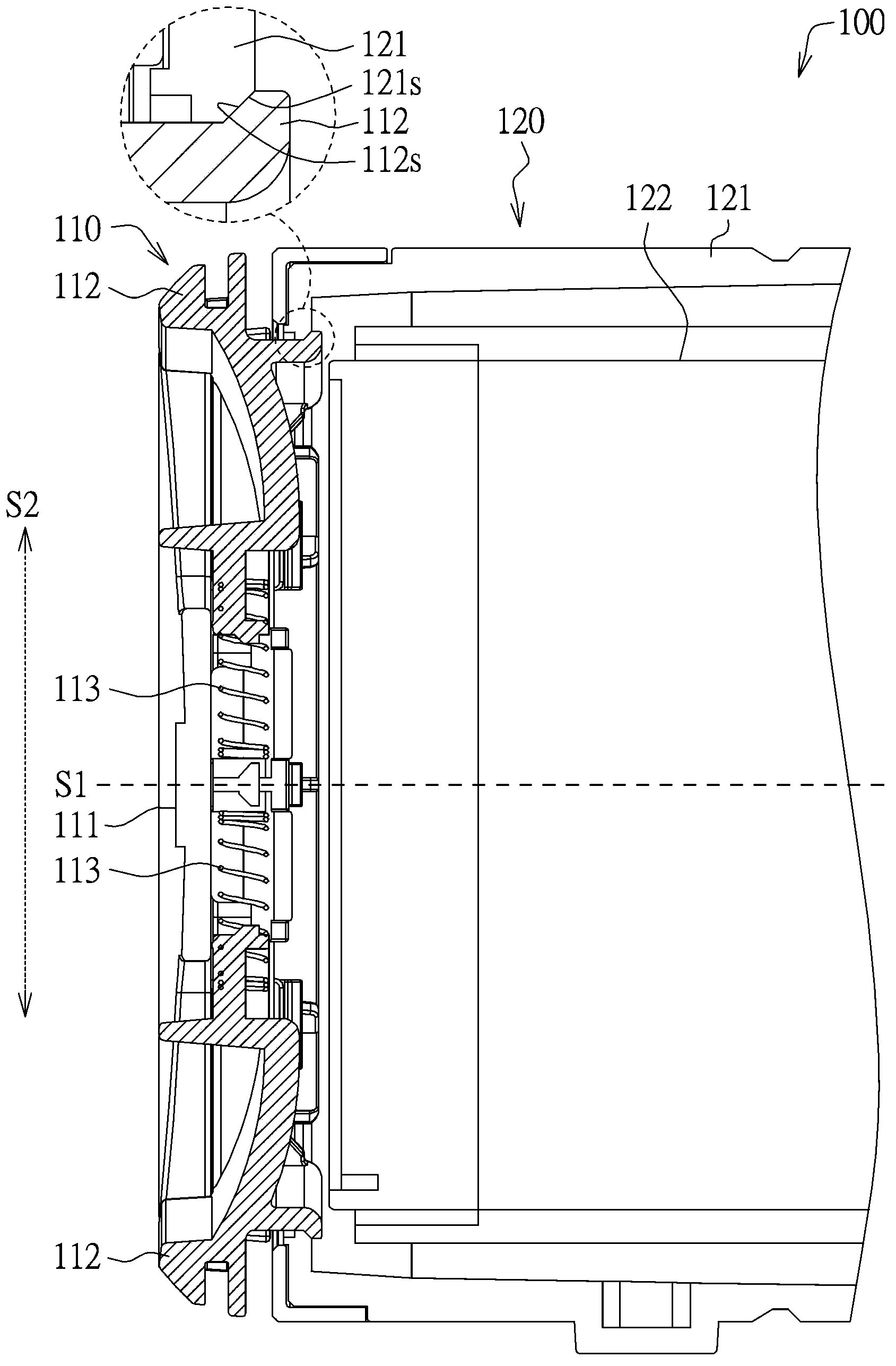

[0018] Please refer to figure 1 , which shows the appearance of an image capture device according to an embodiment of the present invention. The image capture device 100 is, for example, a camera, video camera or other device with image capture function, which at least includes a lens group 10, the lens group 10 has an optical axis and includes a lens cover 110 and a lens mechanism 120, wherein the lens cover 110 can be covered Hold the lens mechanism 120 to protect the optical elements (not shown) in the lens mechanism 120, such as the lens, from accidents such as falling dust, scratches or liquid splashes.

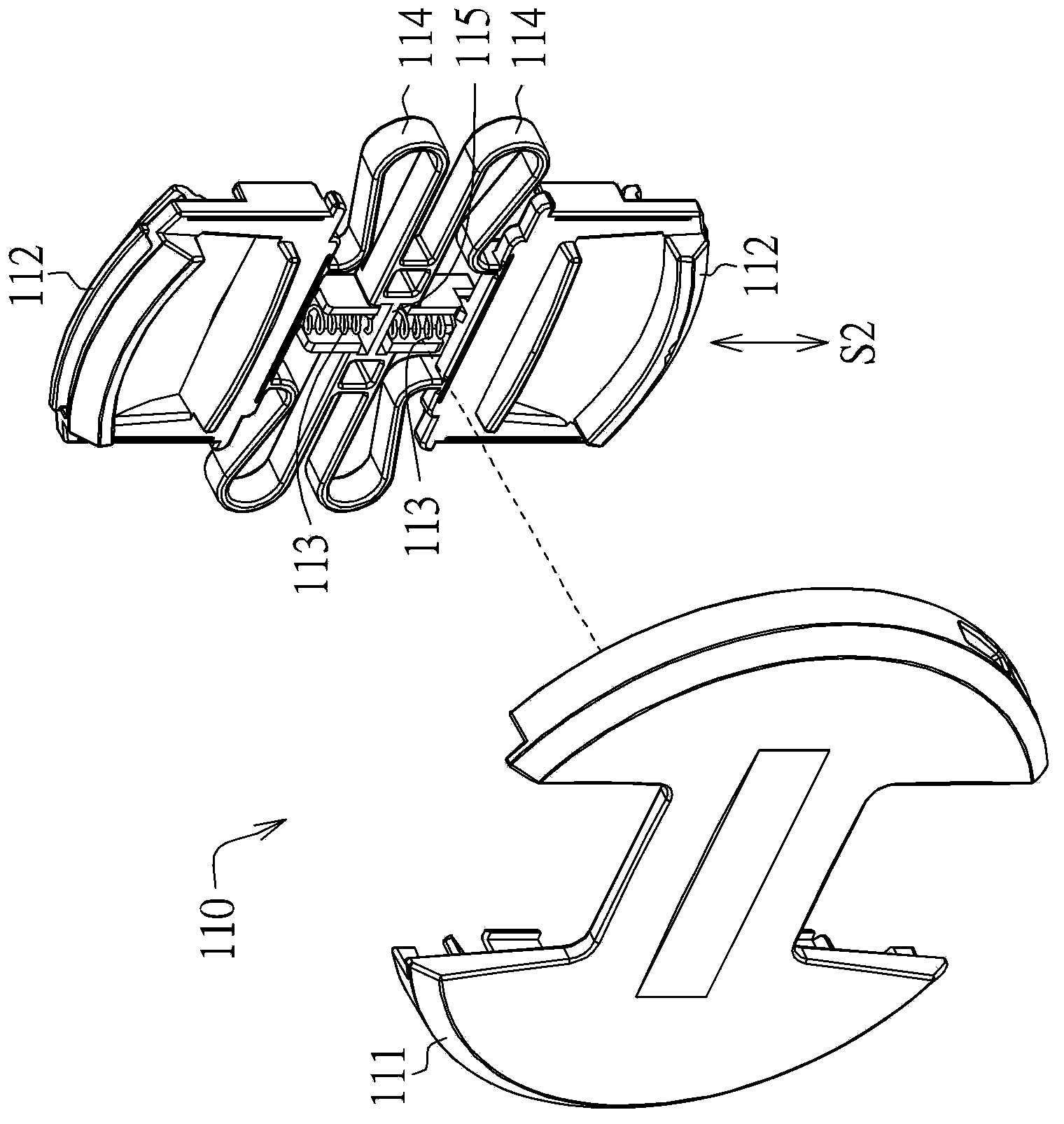

[0019] Please refer to figure 2 , which shows figure 1 An exploded view of the lens cap. The lens cover 110 has a central axis (not shown) and includes a base 111 , two movable elements 112 , two elastic elements 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com