Pit removing machine

The technology of a pit lifter and a hydraulic motor is applied in vehicle maintenance, shunting equipment, vehicle control devices, etc., which can solve the problems of tires falling into pits and unable to escape, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

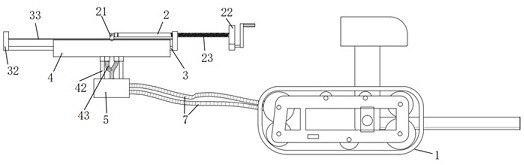

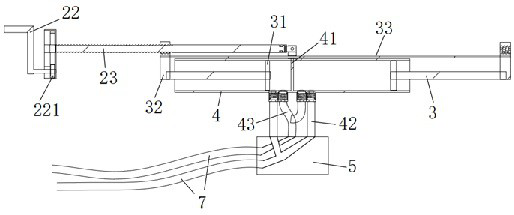

[0026] like figure 1 - As shown in 5, a pit remover includes a base 1, a push rod 2, a piston rod 3, a hydraulic pipe 4, a confluence valve 5, a hydraulic motor 6 and two oil pipes 7,

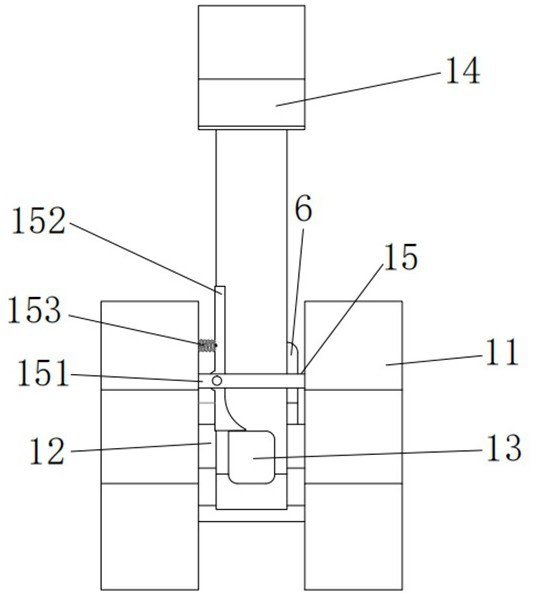

[0027] The base 1 includes two crawler belts 11, several connecting rods 12 connecting the two crawler belts 11 together, a crowbar 13, a top seat 14 and a limit assembly 15, and the crowbar 13 and one of the connecting rods 12 connection; the top seat 14 is connected to the connection between the pry bar 13 and the connecting rod 12; the limit assembly 15 includes a support plate 151, a top plate 152 and a spring, and the two ends of the support plate 151 are respectively connected to two crawlers 11, the top plate 152 is connected to the support plate 151, the top plate 152 is an L-shaped structure, and the middle part of the top plate 152 is overlapped with one side of the crowbar 13; the two ends of the spring are respectively connected to the track 11 and the top of the top plate 152; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com