Projector optical machine with automatic focusing function

A projector optical-mechanical and auto-focusing technology, applied in the field of optical-mechanical focusing, can solve problems such as excessive size, slight lens shift, and trouble.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

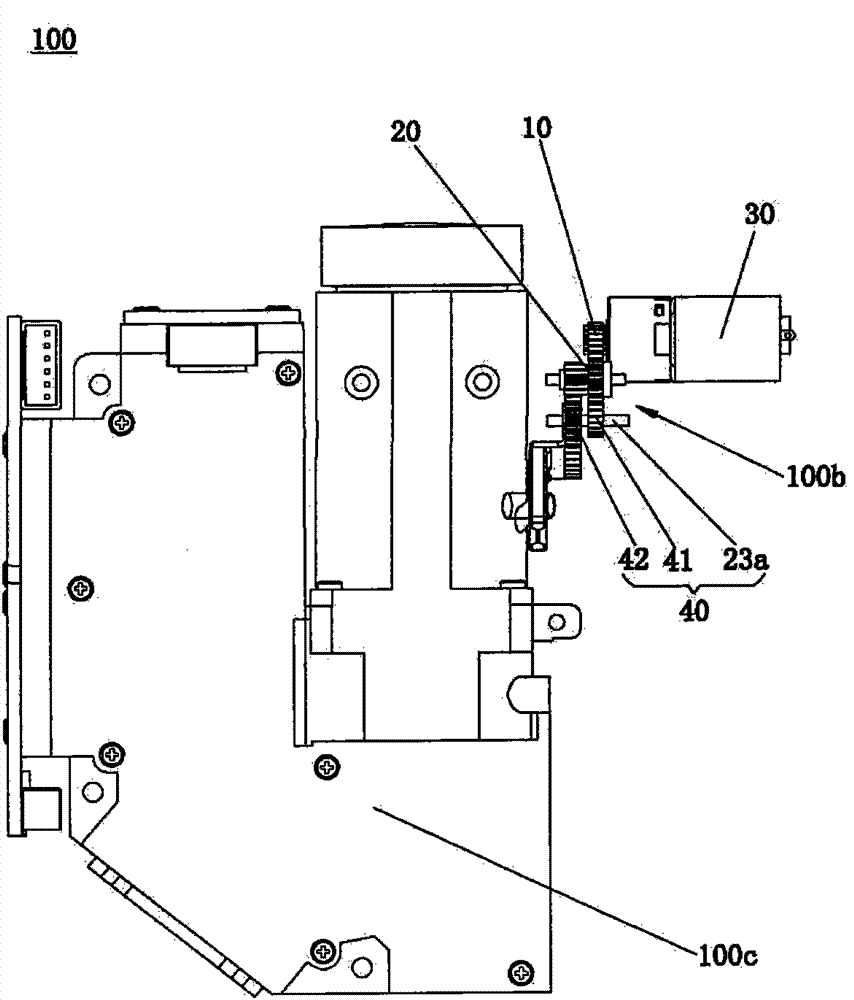

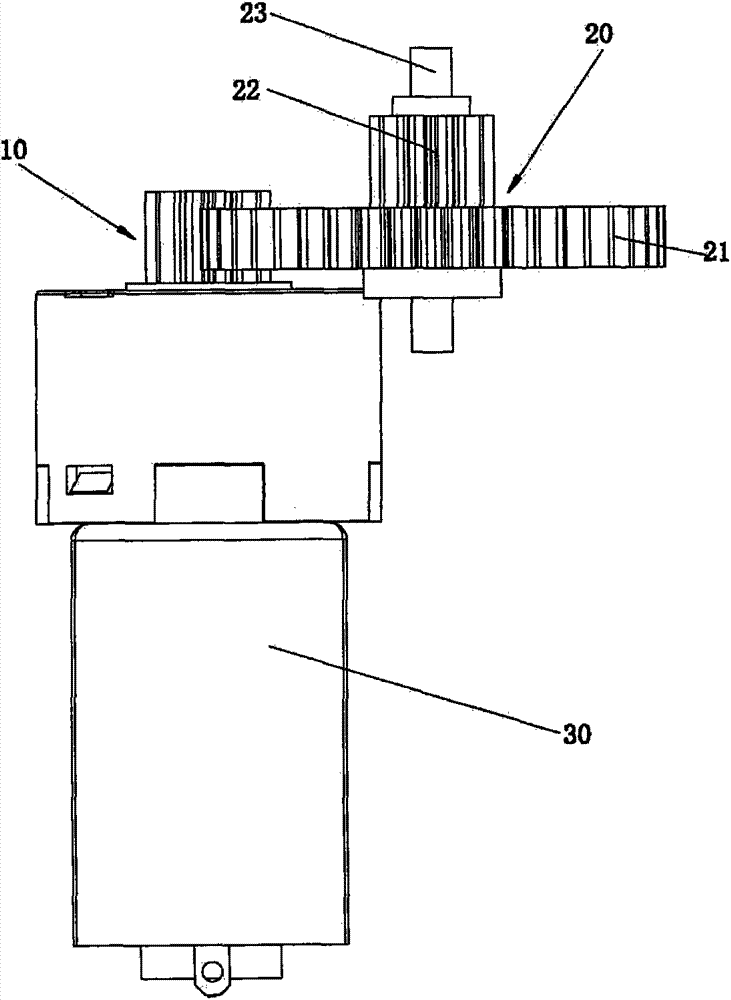

[0018] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements. As mentioned above, such as figure 2 , 3 As shown in , 4, the projector optical machine 100 with automatic focus function provided by the present invention includes a focus motor gear assembly 100b, and the focus motor gear assembly 100b includes: a driving gear 10, a first driven gear assembly 20 and The motor 30 that drives the driving gear 10 to rotate, the driving gear 10 drives the first driven gear assembly 20 to rotate, as Figure 4 As shown, the driving gear 10 includes a first gear tooth portion 11 and a shaft sleeve 12 integrally structured with the first gear tooth portion 11, and the output shaft (not shown) of the motor 30 passes through the shaft sleeve The side where 12 is located penetrates into the shaft hole (not shown in the figure) of the driving gear 10 to be connected and installed with the driving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com