Patents

Literature

31results about How to "With auto focus function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

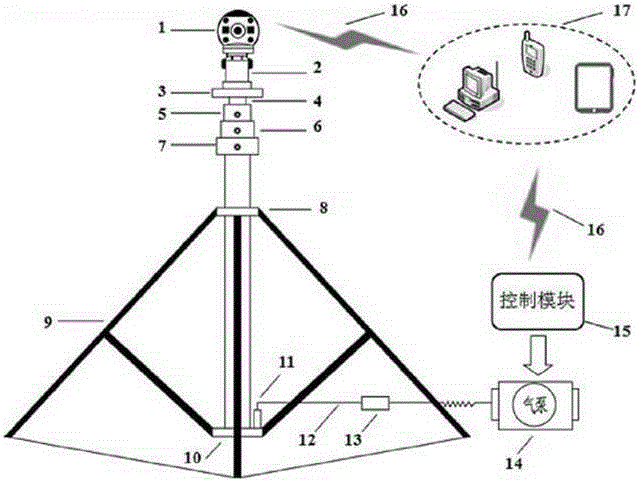

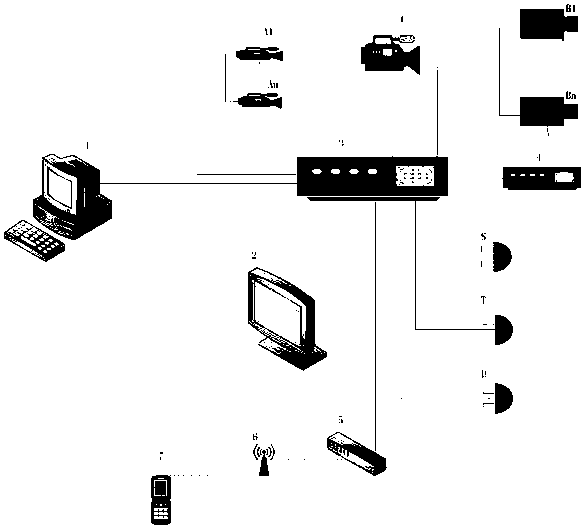

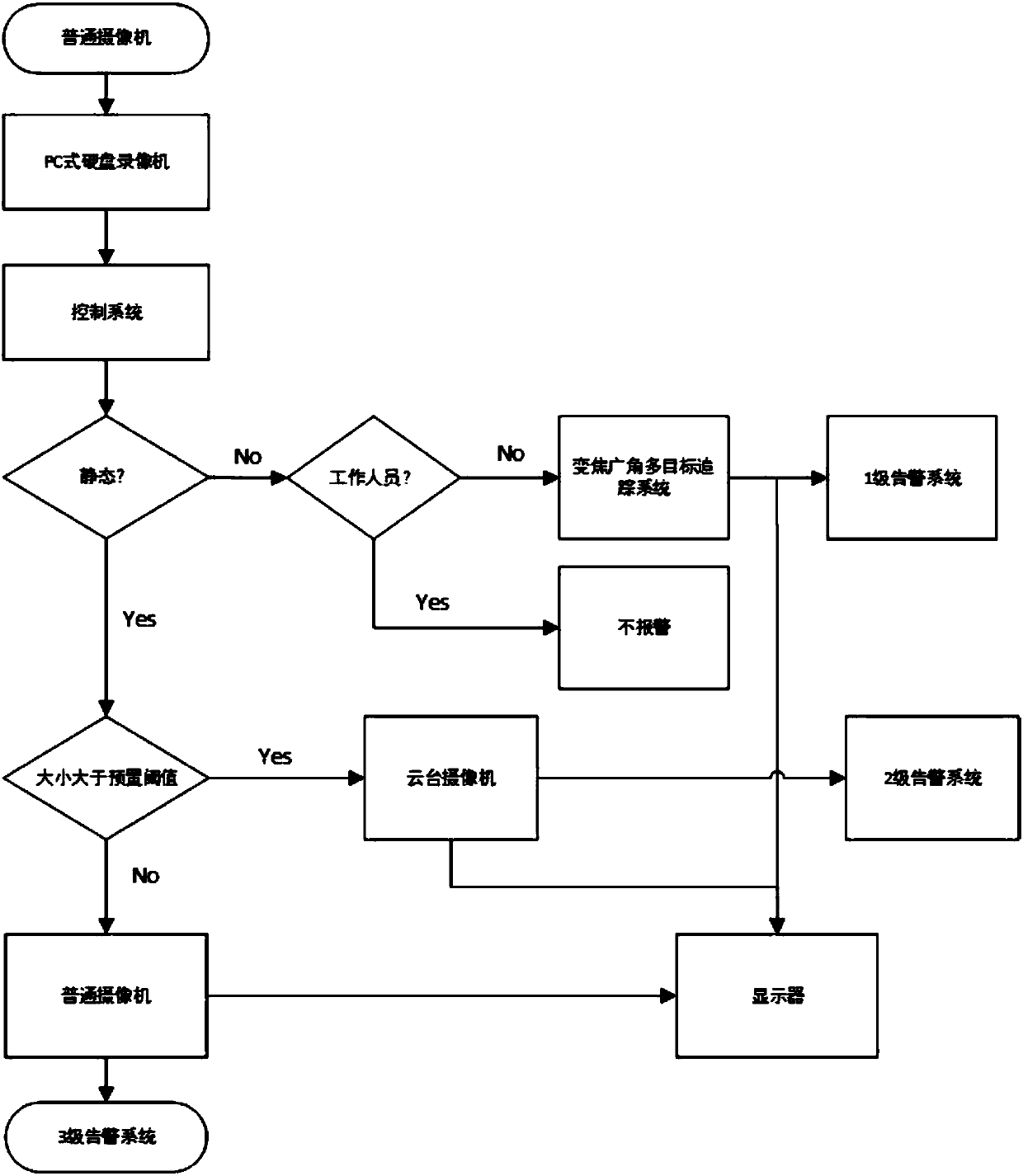

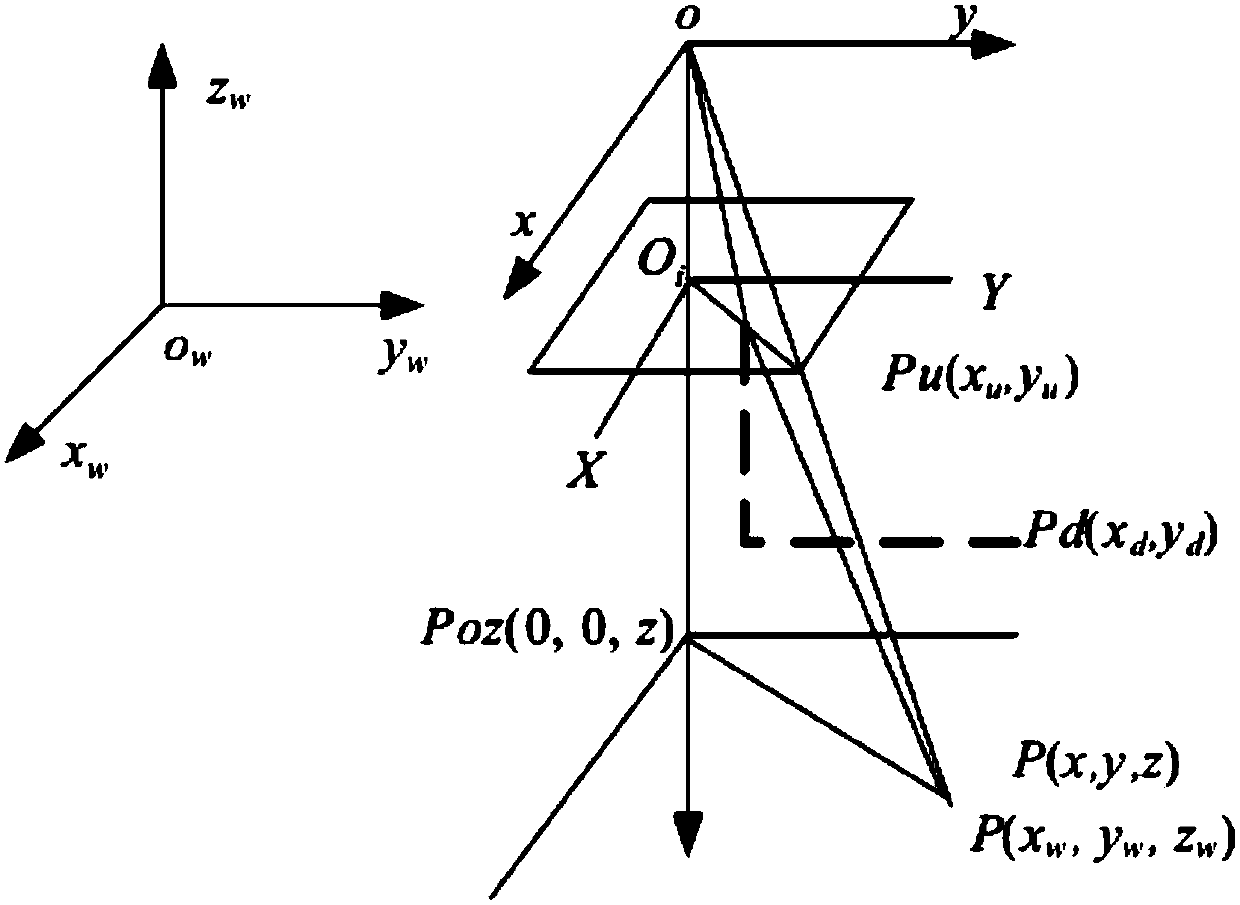

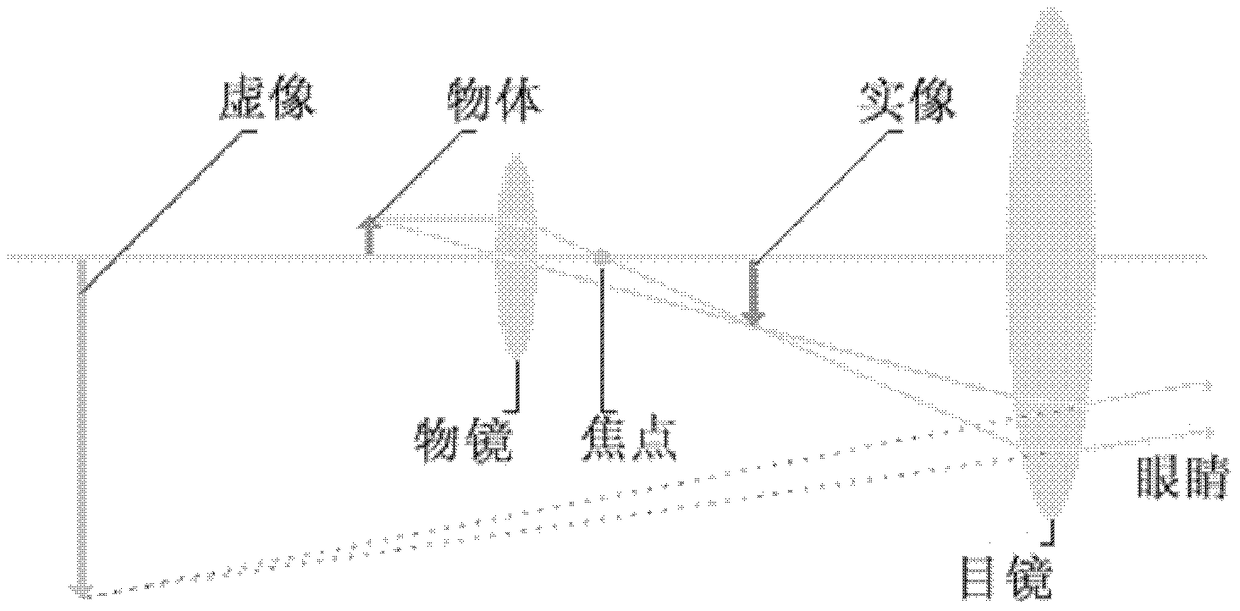

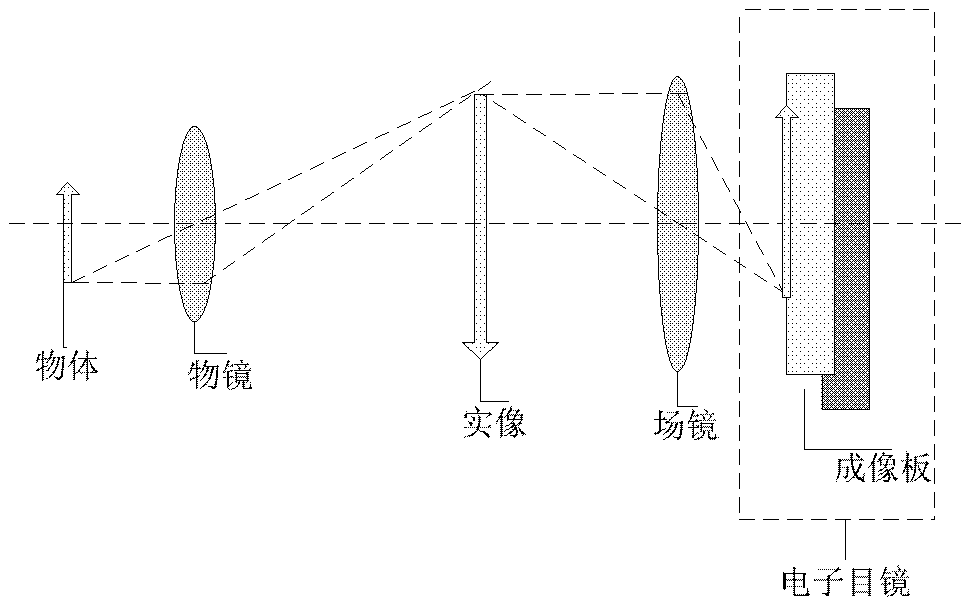

Invasion detecting alarming system based on multi-camera data combination and detecting method thereof

InactiveCN105894702AWith auto focus functionHigh degree of intelligenceClosed circuit television systemsBurglar alarmVideocassette recorderVideo monitoring

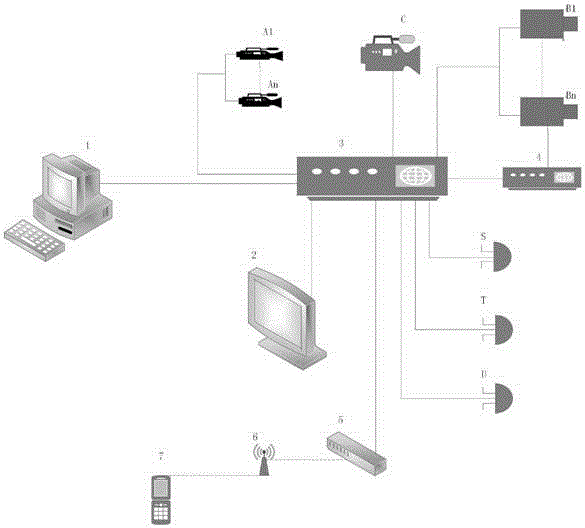

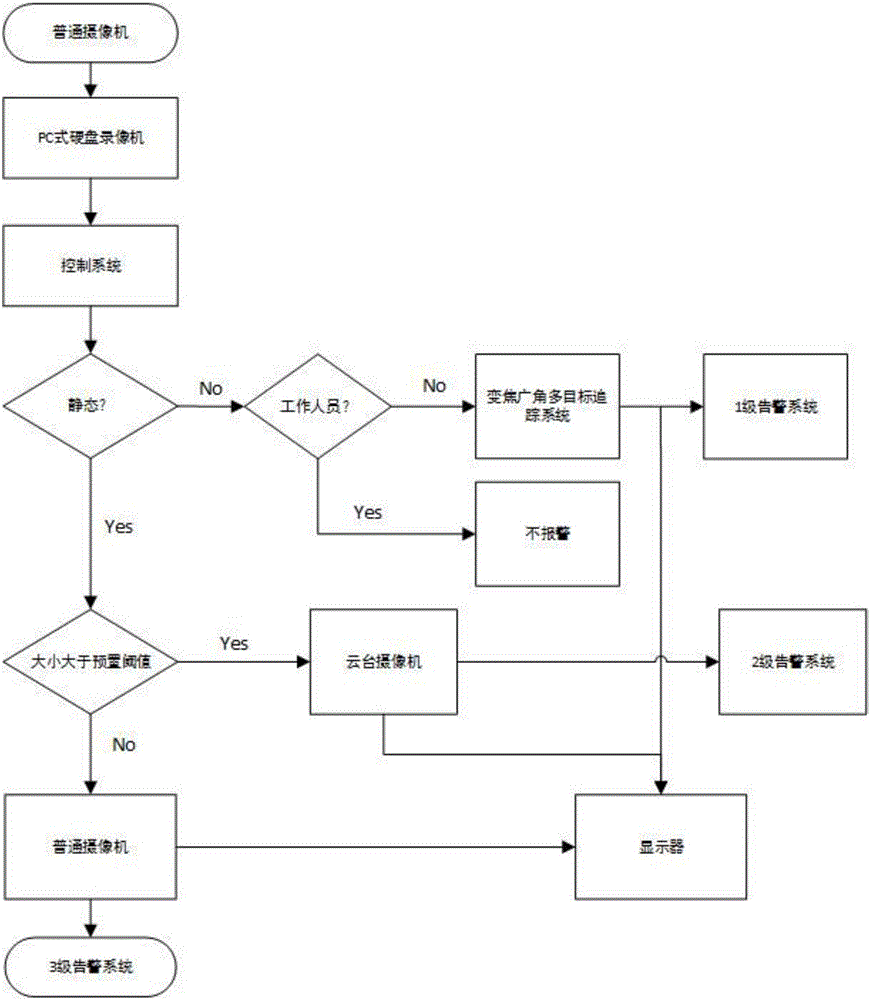

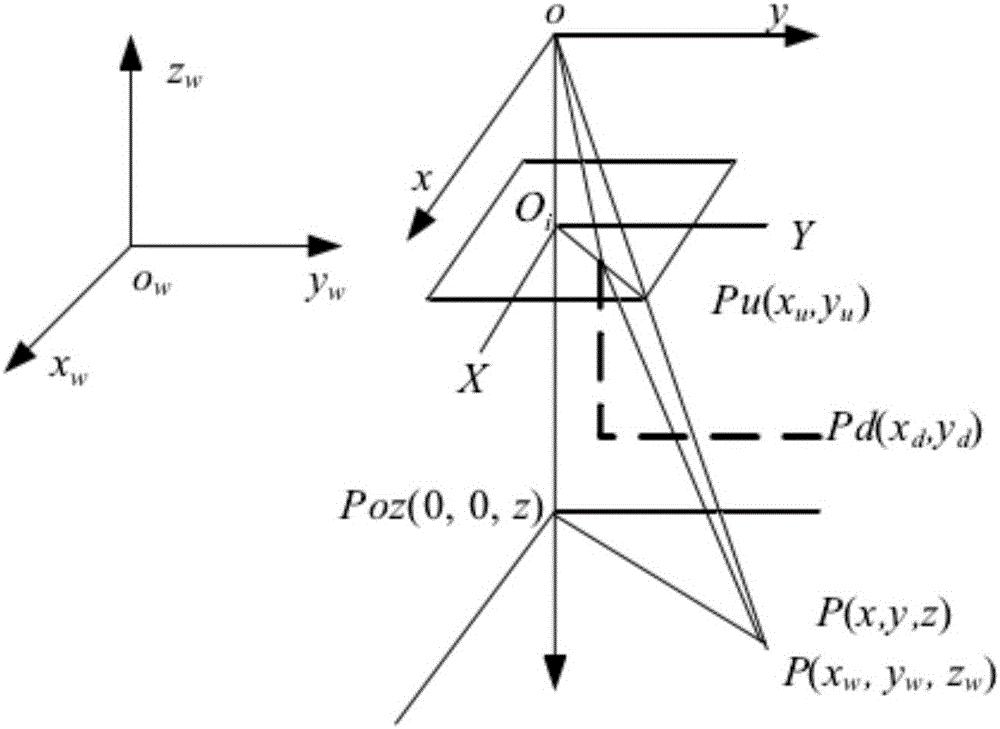

The invention discloses an invasion detecting alarming system based on multi-camera data combination and a detecting method thereof, and belongs to the technical field of video monitoring. The system comprises a common camera, a cloud camera, a zooming wide-angle multi-target tracking system, a PC type hard disk recorder, a control system, a display, a multi-stage alarming processing module and an invader recognizing and treating module. According to the system, an area to be monitored is completely covered with a plurality of cameras; the shot video signals can be digitized and compressed and then transmitted to the control system to recognize an invader and respond to the corresponding alarming level. The system is applicable to scenes or channels with high requirement on safety production, such as a factory area, a tunnel, a warehouse and an airport; the system can perform monitoring and alarming at different conditions.

Owner:NANJING UNIV OF TECH +1

Optical die set, camera and mobile terminal equipment

InactiveCN101251706ASharpness effectWith auto focus functionTelevision system detailsPrintersCamera lensOptical Module

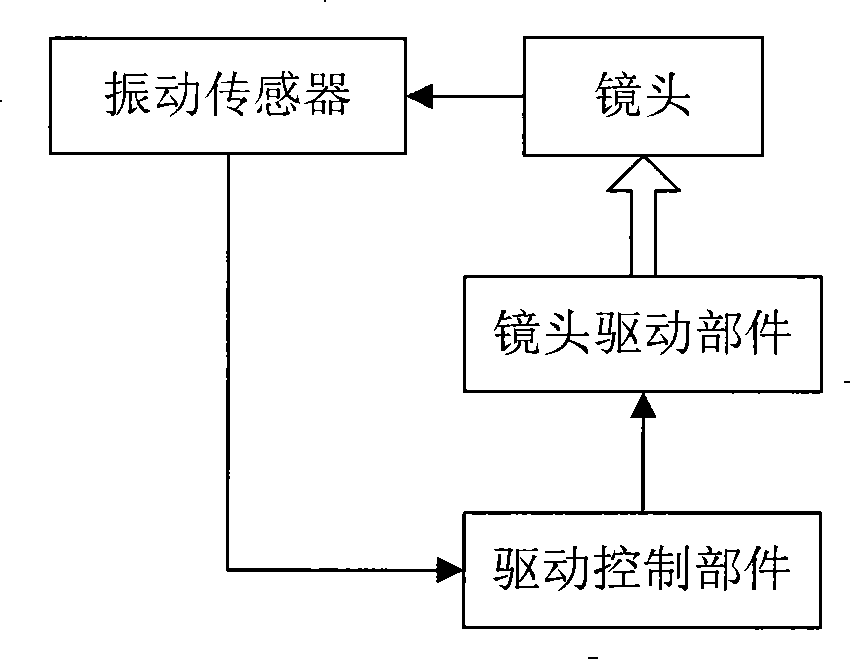

The invention discloses an optical module, a camera and a mobile terminal device. The optical module comprises a lens, a lens driving component, a driving control component and a vibration transducer, wherein, the vibration transducer is used for detecting vibration / jitter of the optical module, the camera or the mobile terminal device and transmitting detected signals to the driving control component; the driving control component generates corresponding vibration / jitter compensation signals according to the detection signals of the vibration transducer and drives the lens to perform vibration / jitter compensation motion through the lens driving component. The camera and the mobile terminal device apply the optical module. The optical module, the camera and the mobile terminal device not only have autofocus function but also increase shock-proof function and overcome the defect that the image resolution is affected by vibration / jitter of the optical module, the camera or the mobile terminal device.

Owner:HONG KONG APPLIED SCI & TECH RES INST

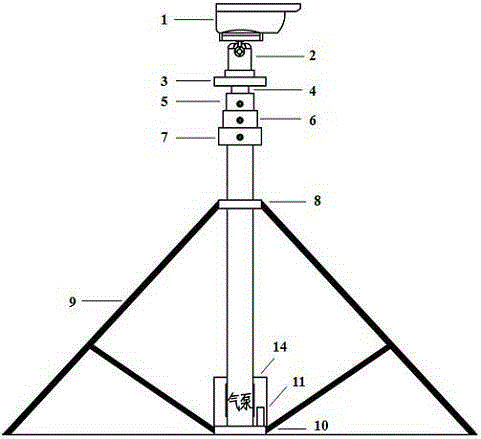

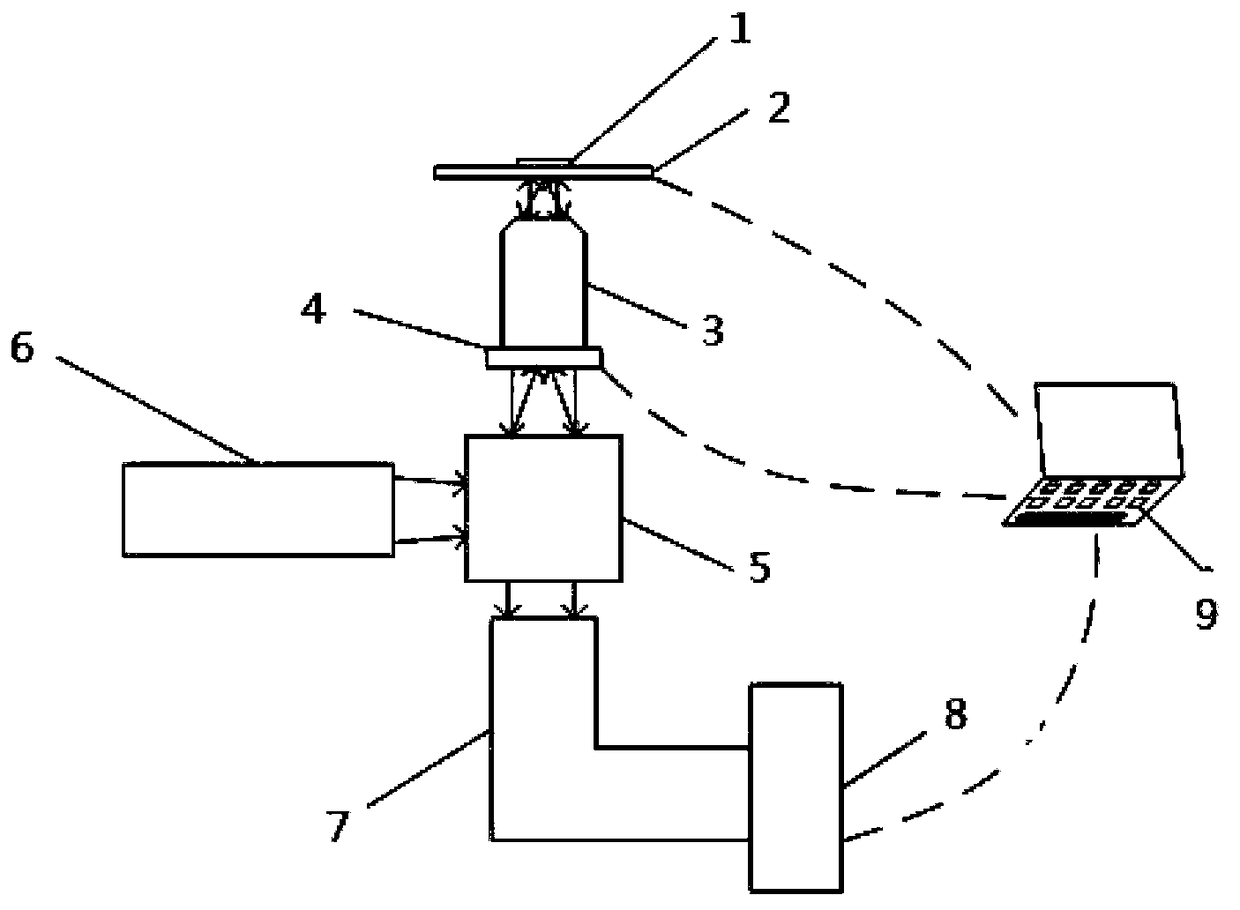

Pneumatic type vertical lift remote monitoring system for crop image

InactiveCN105187780AWith auto focus functionMeet the needs of observation from different anglesClosed circuit television systemsStands/trestlesAuto regulationMarine engineering

The invention discloses a pneumatic type vertical lift remote monitoring system for a crop image. The remote monitoring system comprises three parts including a pneumatic type lifting rod, a cradle head camera and an Internet of Things remote control system. The Internet of Things remote control system comprises a lifting rod state remote control module and a crop imaging remote control module. The lifting rod is arranged in a proper position in the field, the cradle head camera is fixed at a camera saddle at the top end of the lifting rod, and height adjustment of the lifting rod and camera imaging are both completed by the remote control system. The remote monitoring system has the advantages that the structure is simple, the height of the lifting rod and the shooting angle of the camera can be remotely and automatically adjusted, the crop shooting can be carried out from different lateral surfaces and orientations, the crop imaging from different lateral surfaces can be obtained, and the remote monitoring system is convenient for a user to master the crop growth situation more accurately and for a crop specialist to carry out remote diagnosis. Through the Internet of Things remote control system, the remote monitoring system supports snapshot and uploading of a field image and can utilize information, such as crop growth, color and texture, from the image.

Owner:北京恺琳科技发展有限公司

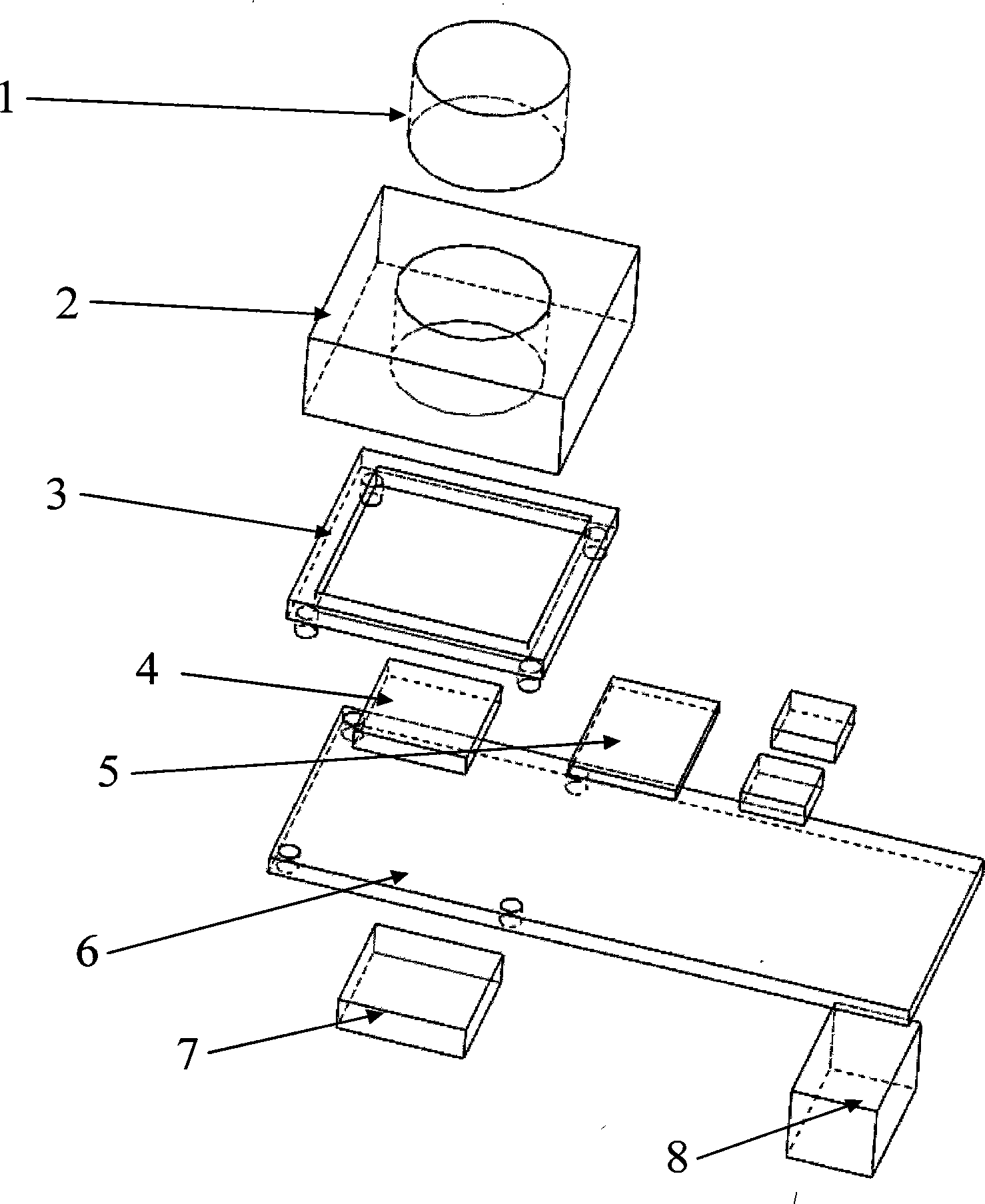

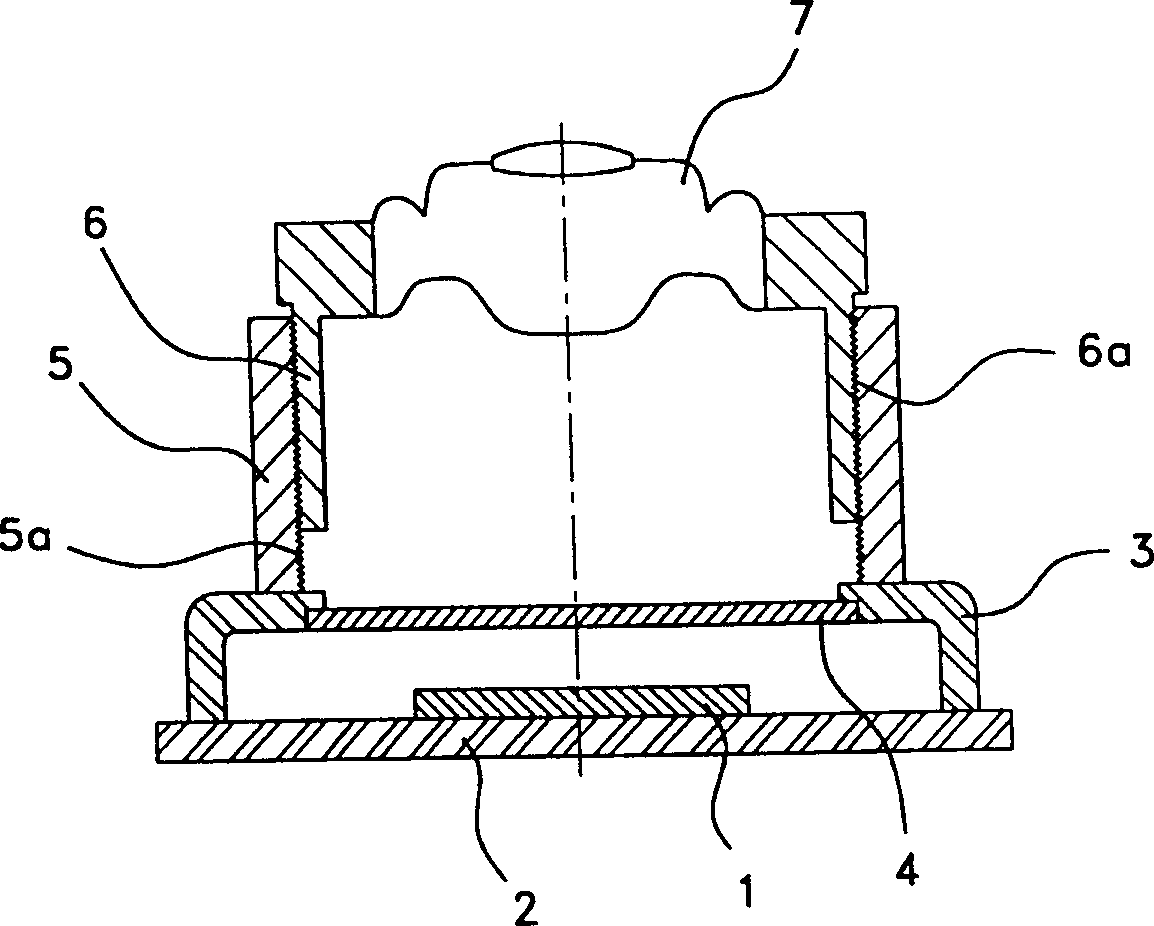

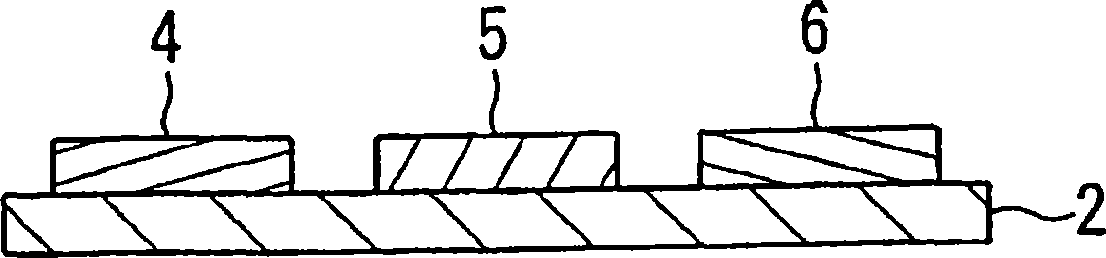

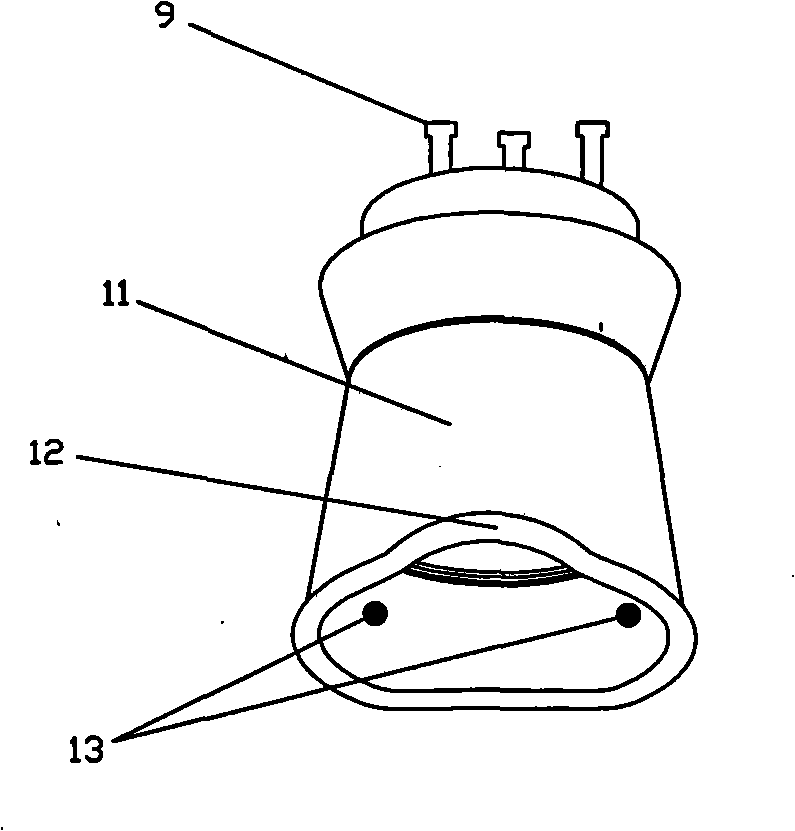

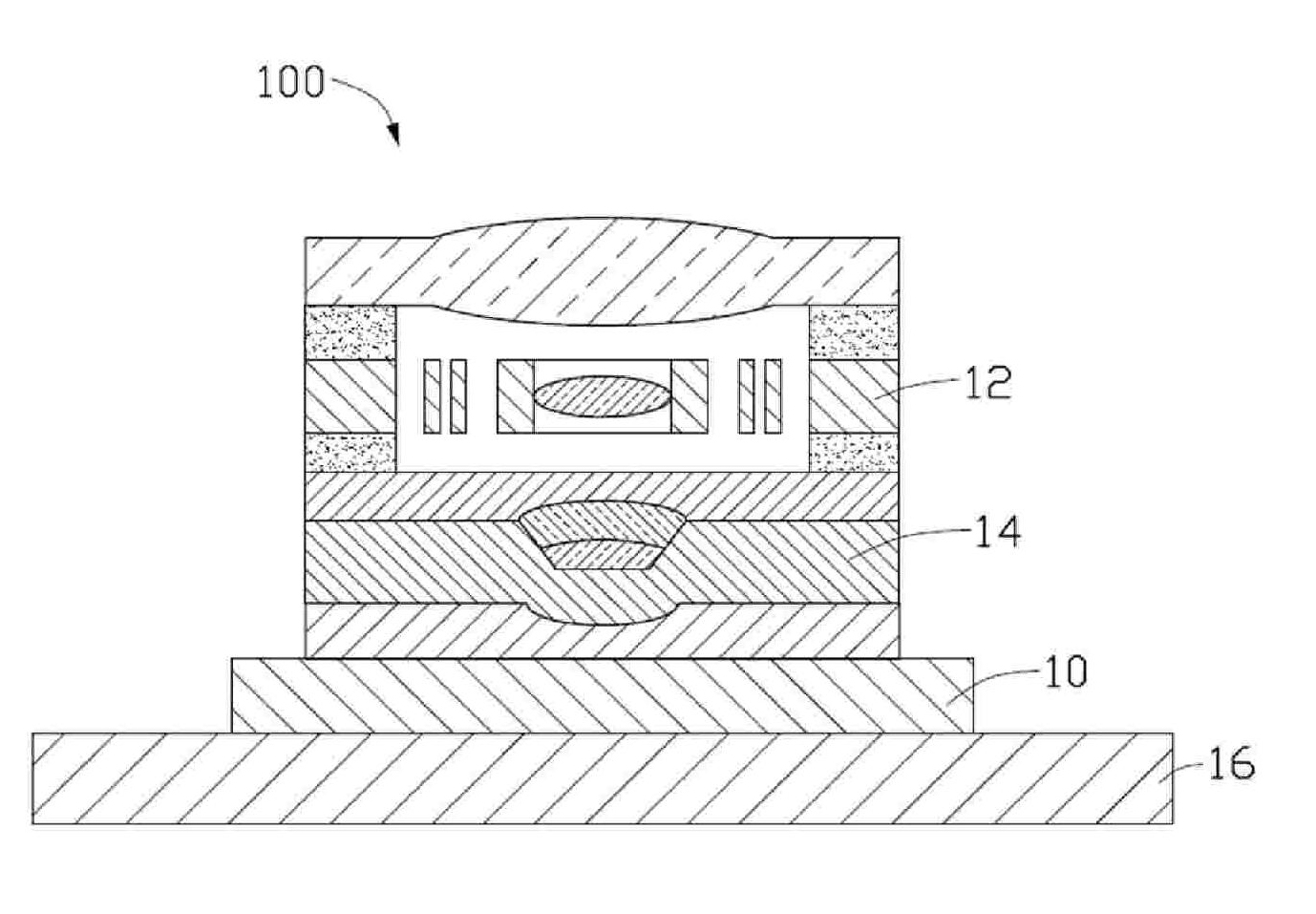

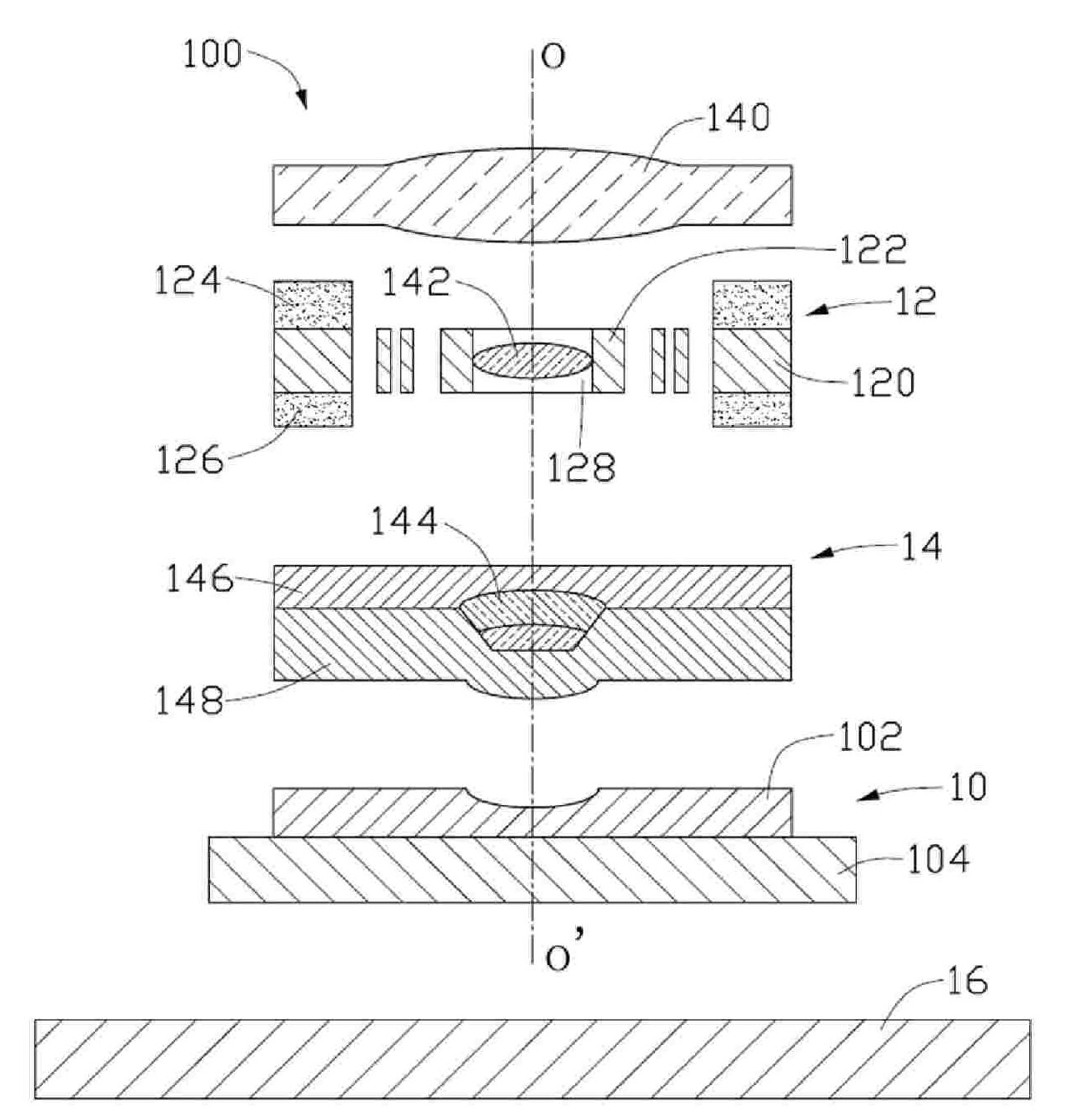

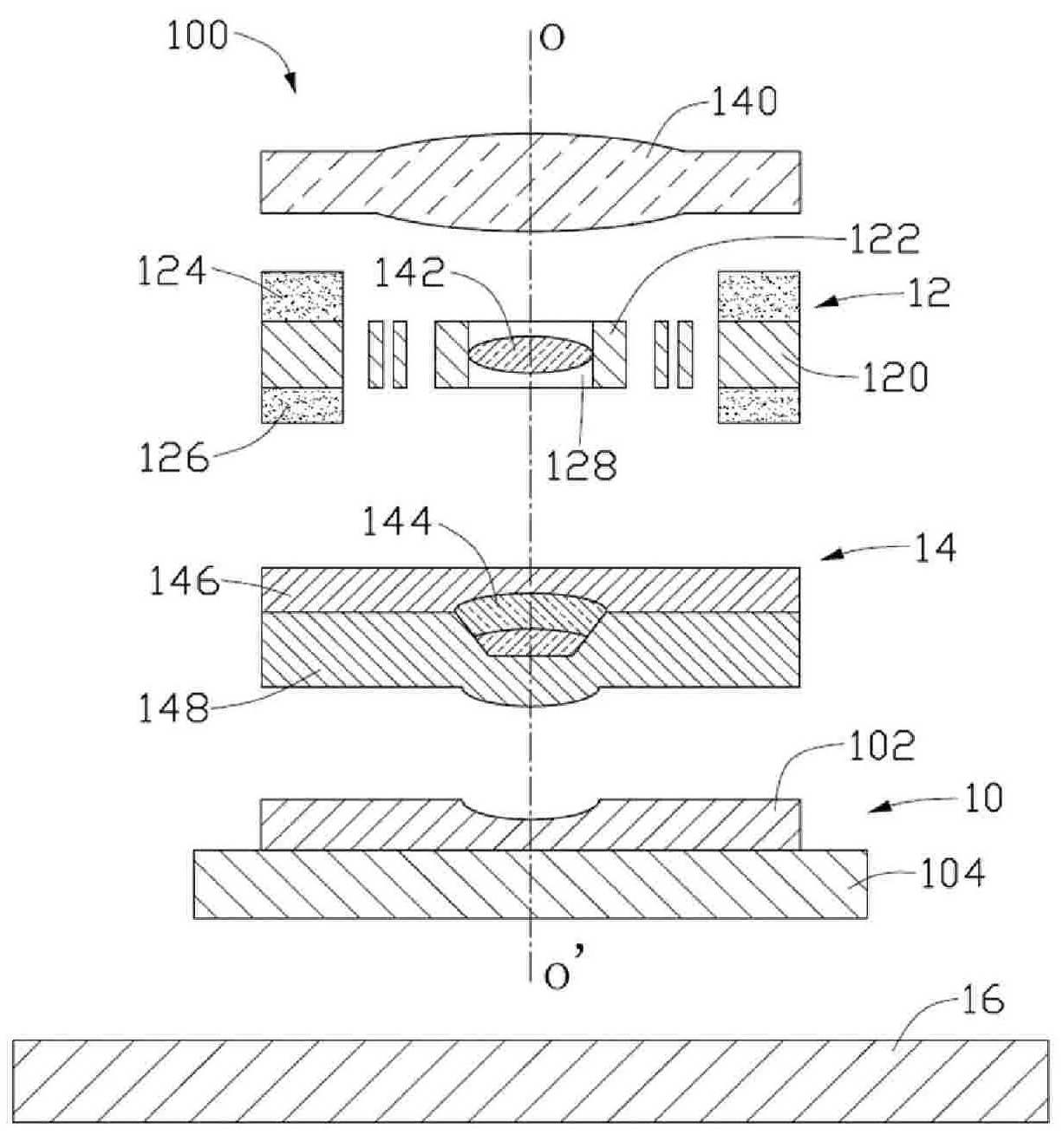

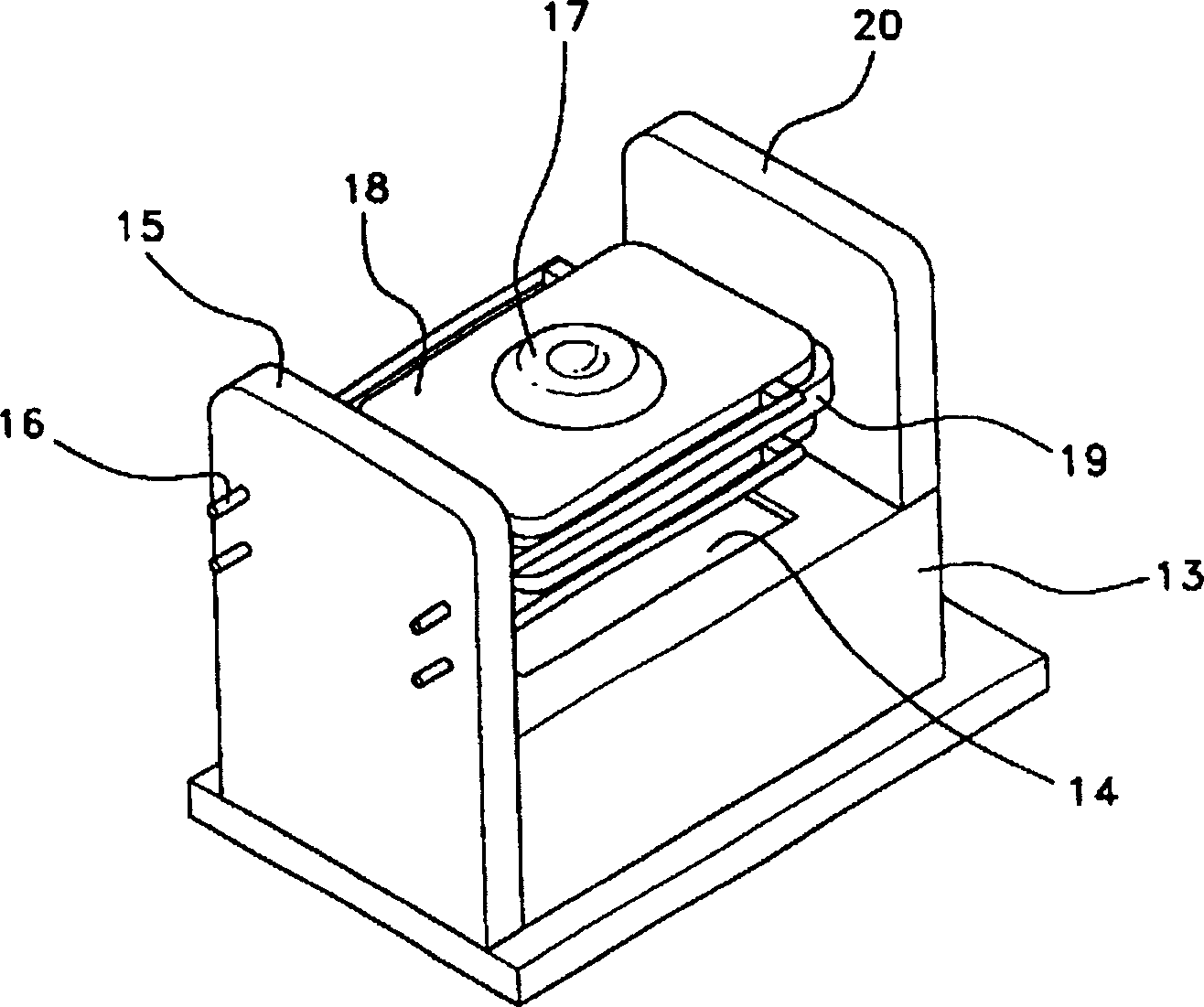

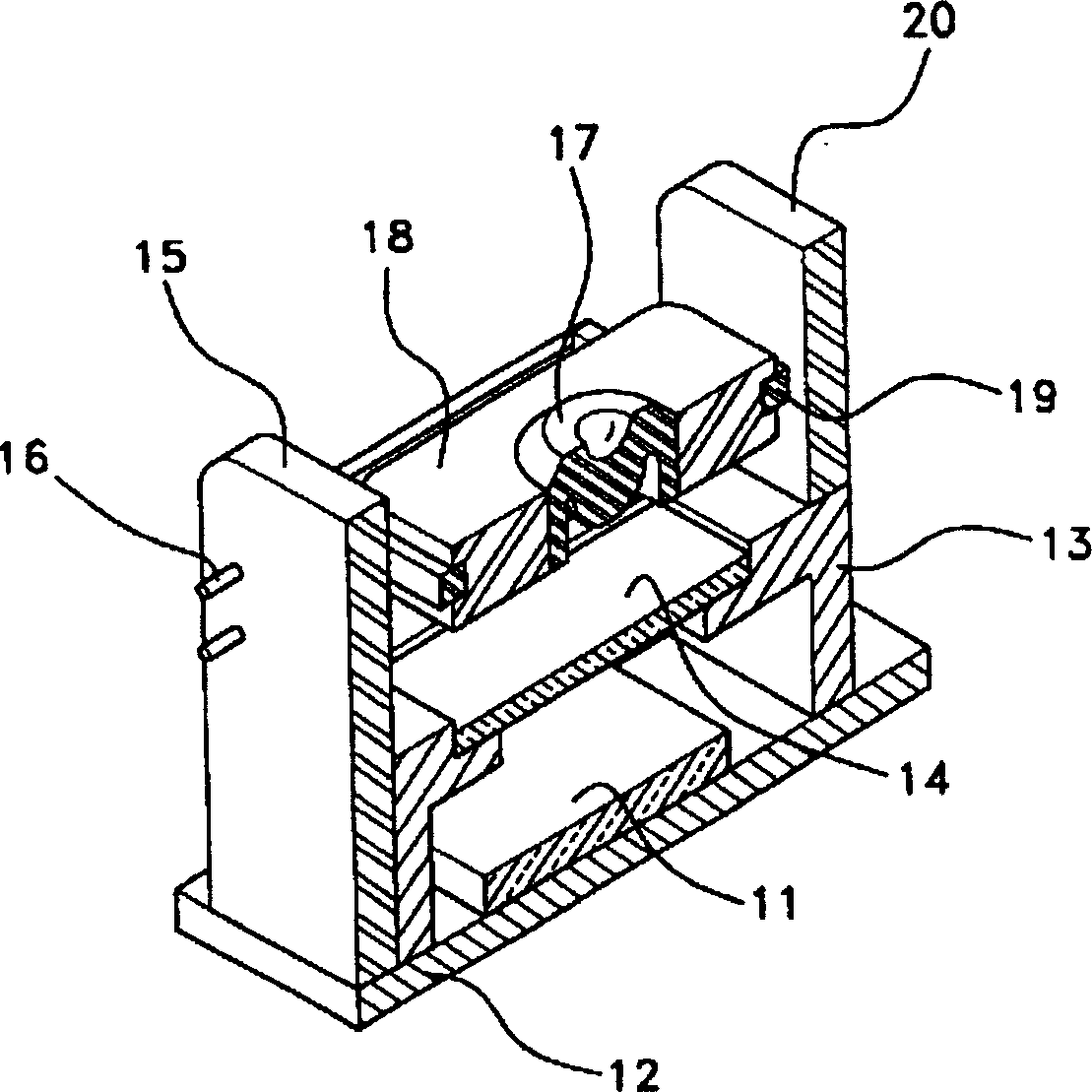

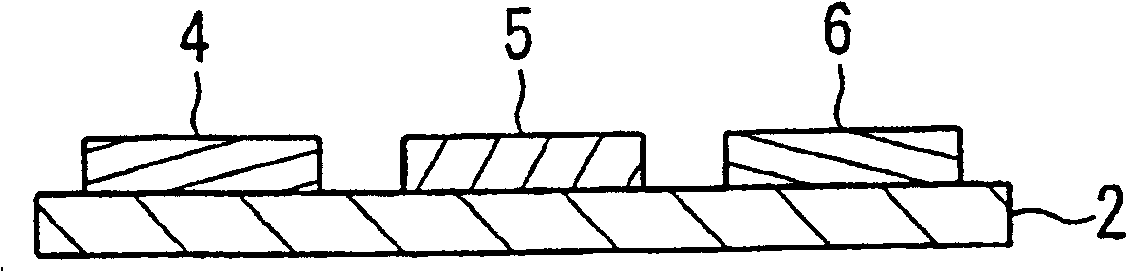

Picture module

InactiveCN1402036AWith auto focus functionTelevision system detailsSolid-state devicesComputer moduleMiniaturization

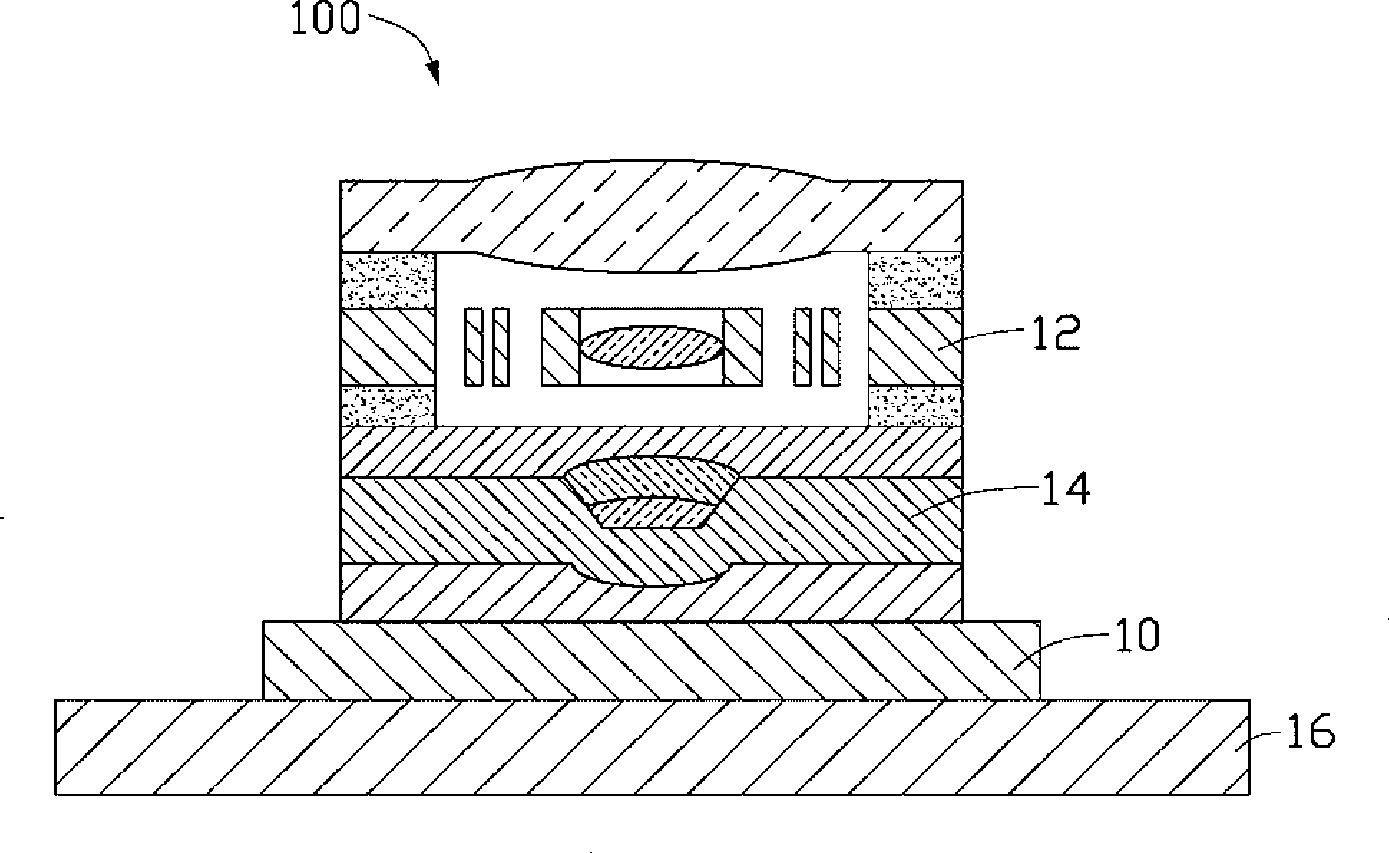

Disclosded an image module having a function of an automatic focus adjustment based on a COB system for miniaturization and unification. The image module includes an image packaging unit, which comprises a sensor for sensing a picture image, a substrate including the sensor, a sensor cover for covering the sensor and the substrate at the outside and a sensor filter for blocking an outer environment and passing light between the sensor cover and the sensor only; and a lens blade unit, which comprises a lens blade having a lens to transmit the light at a center and a driving coil on a surface thereof, an elastic means for supplying a current to the driving coil of the lens blade and supporting the lens blade, and a magnet for forming a magnetic field to enable the lens blade to shift up and down due an electromagnetic force, and thereby lowering power consumption and production cost and improving reliability on a product thereof.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

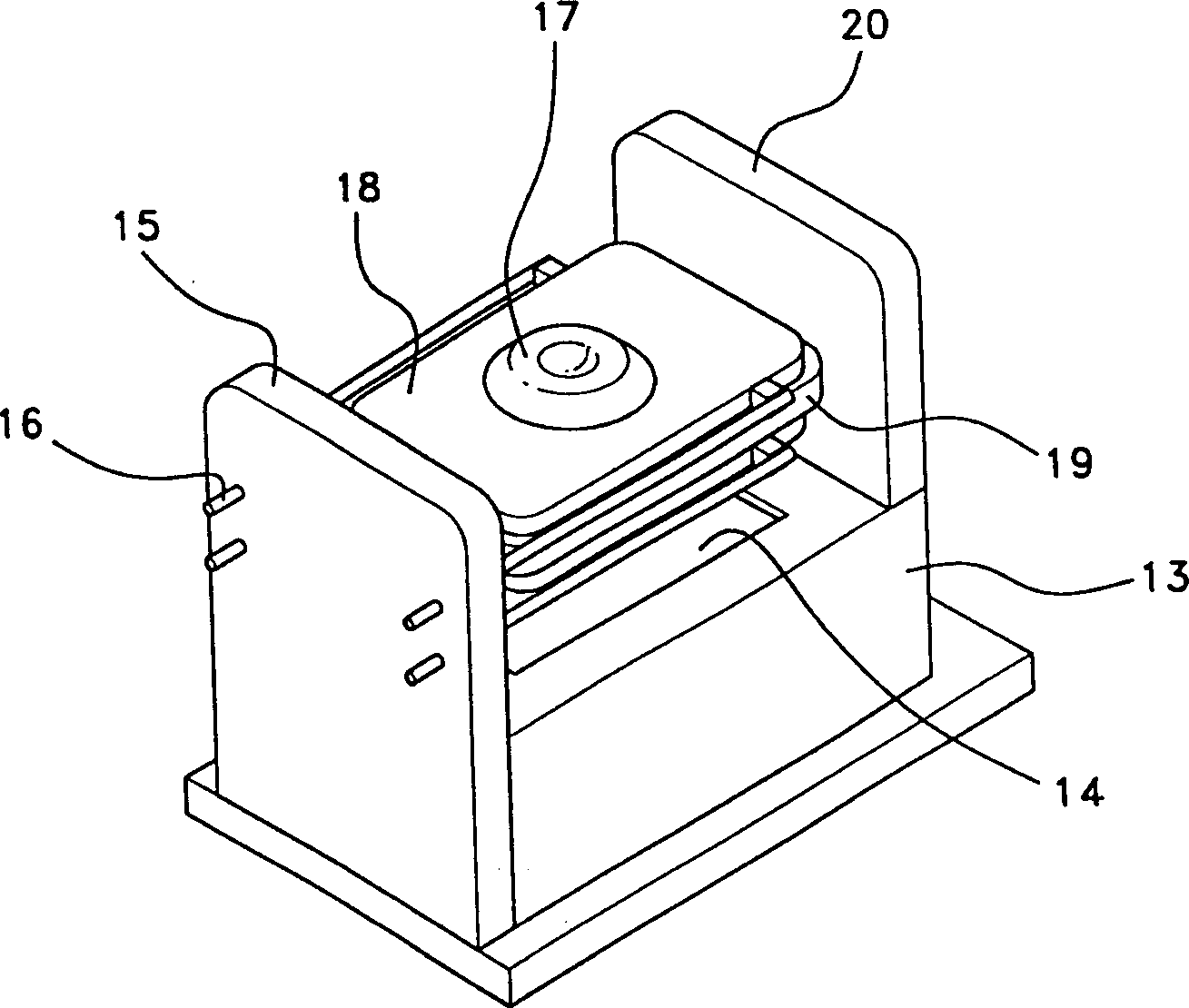

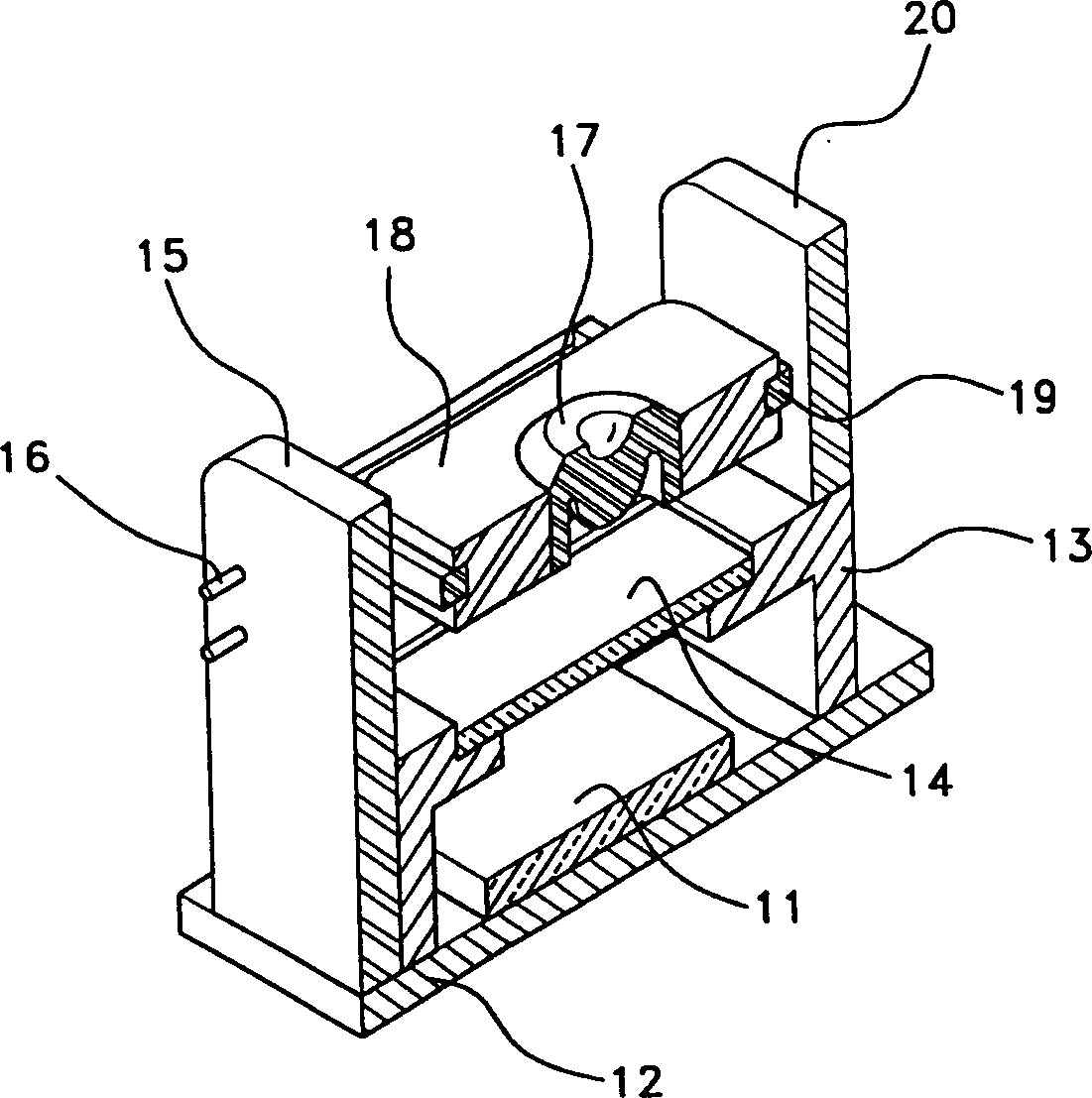

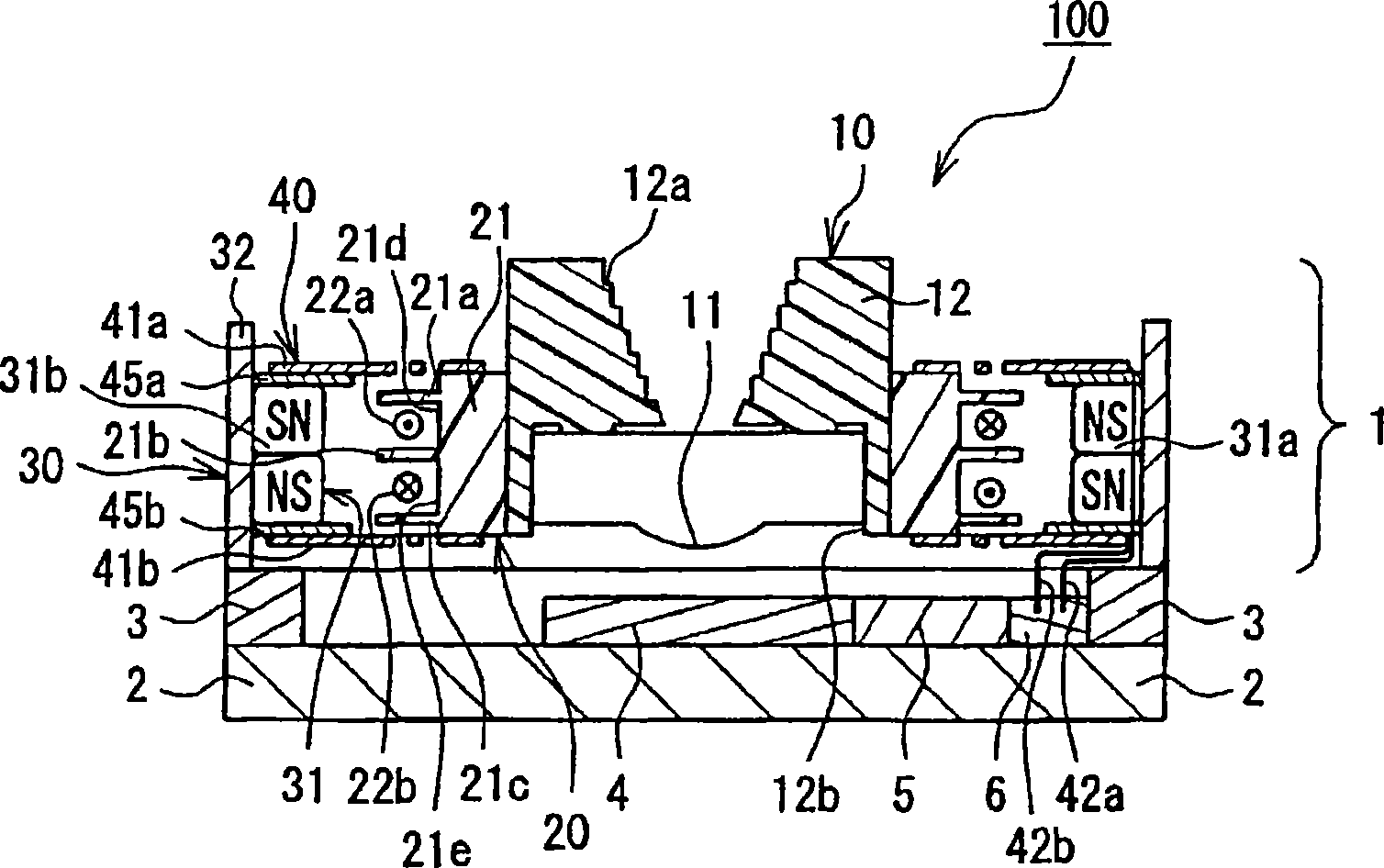

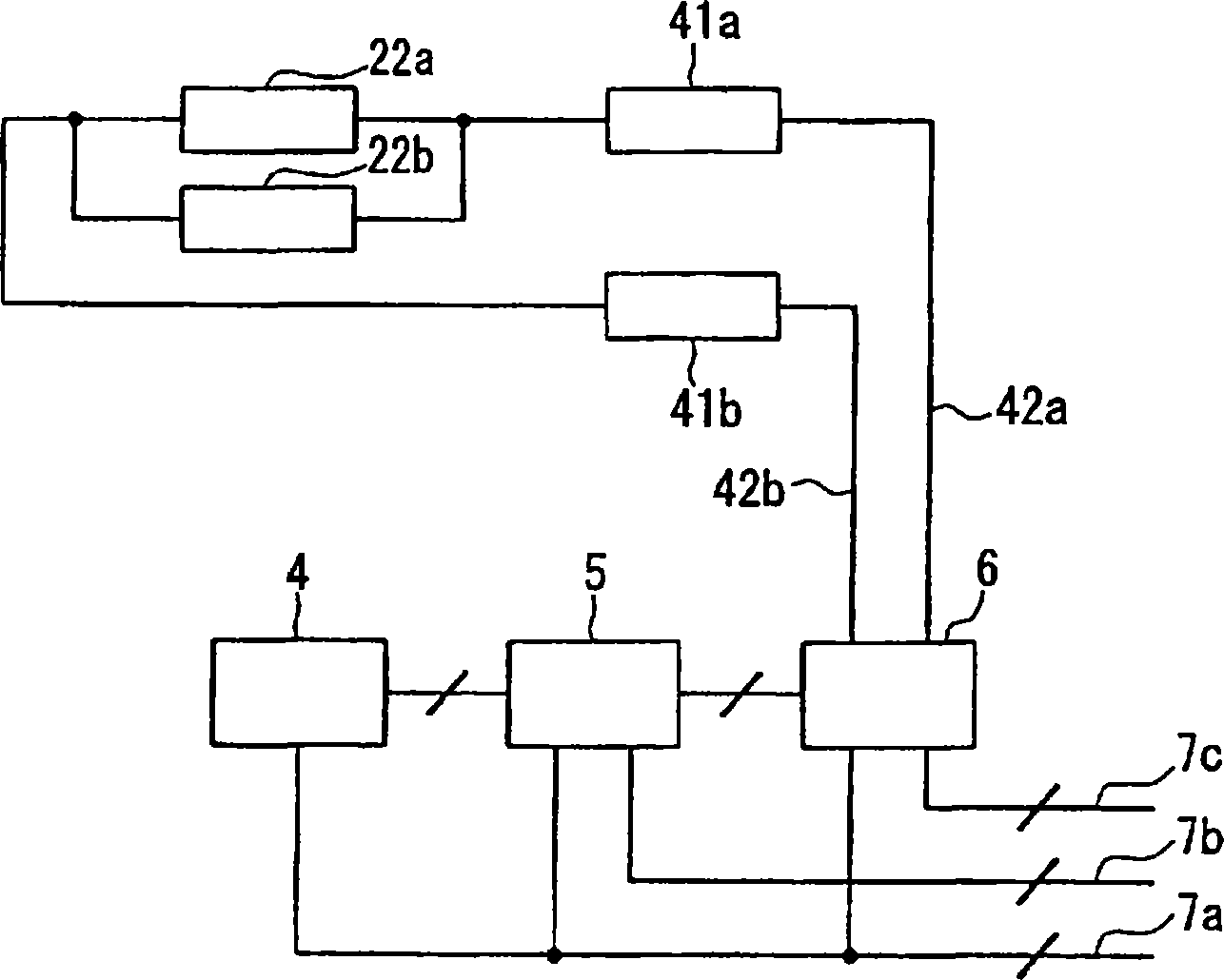

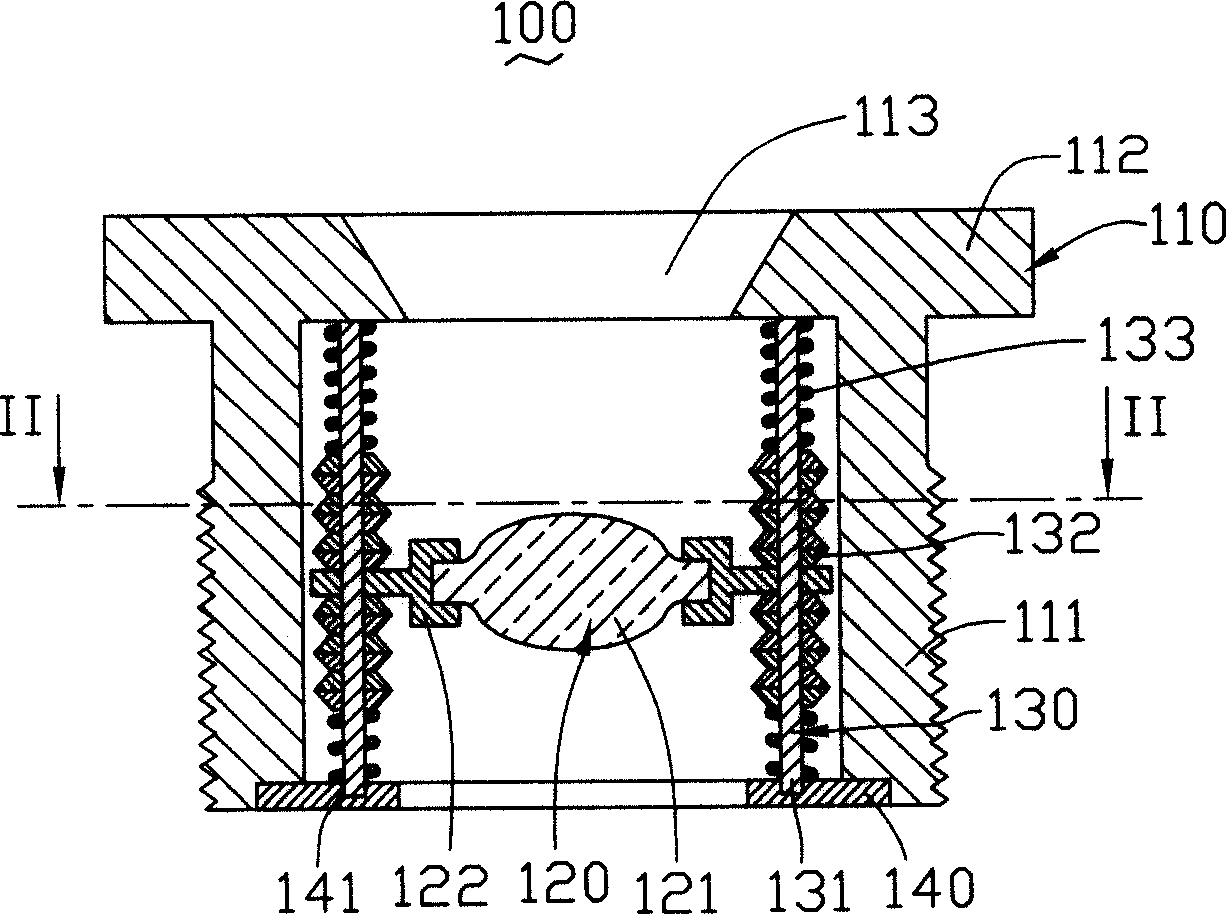

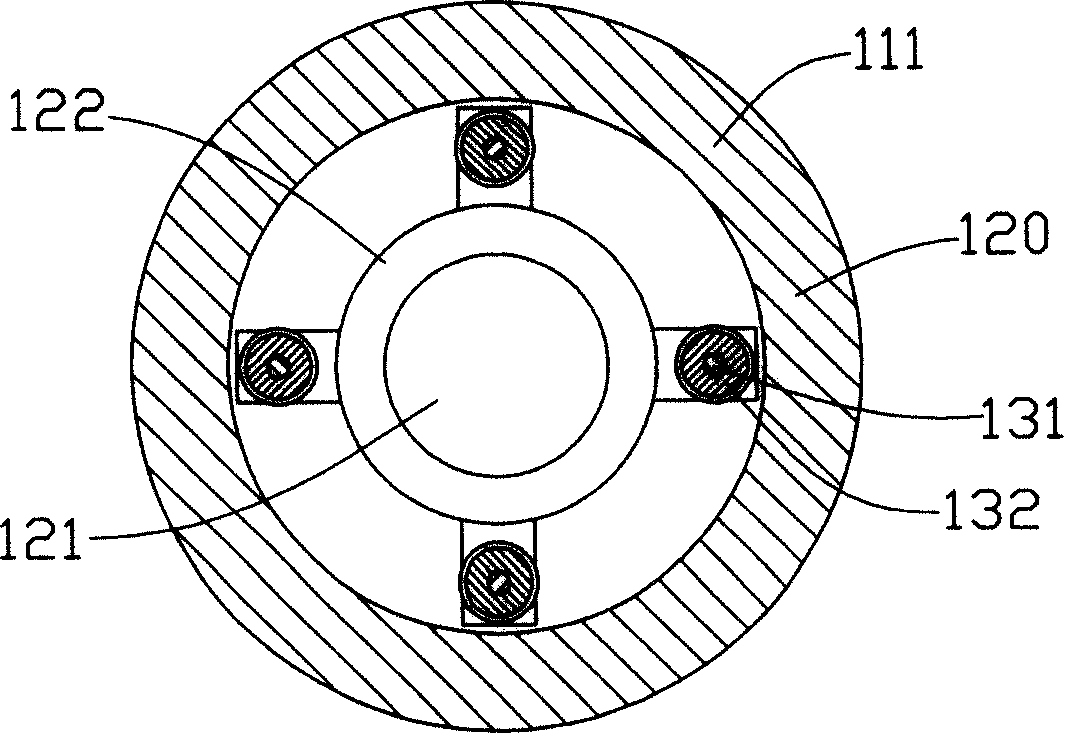

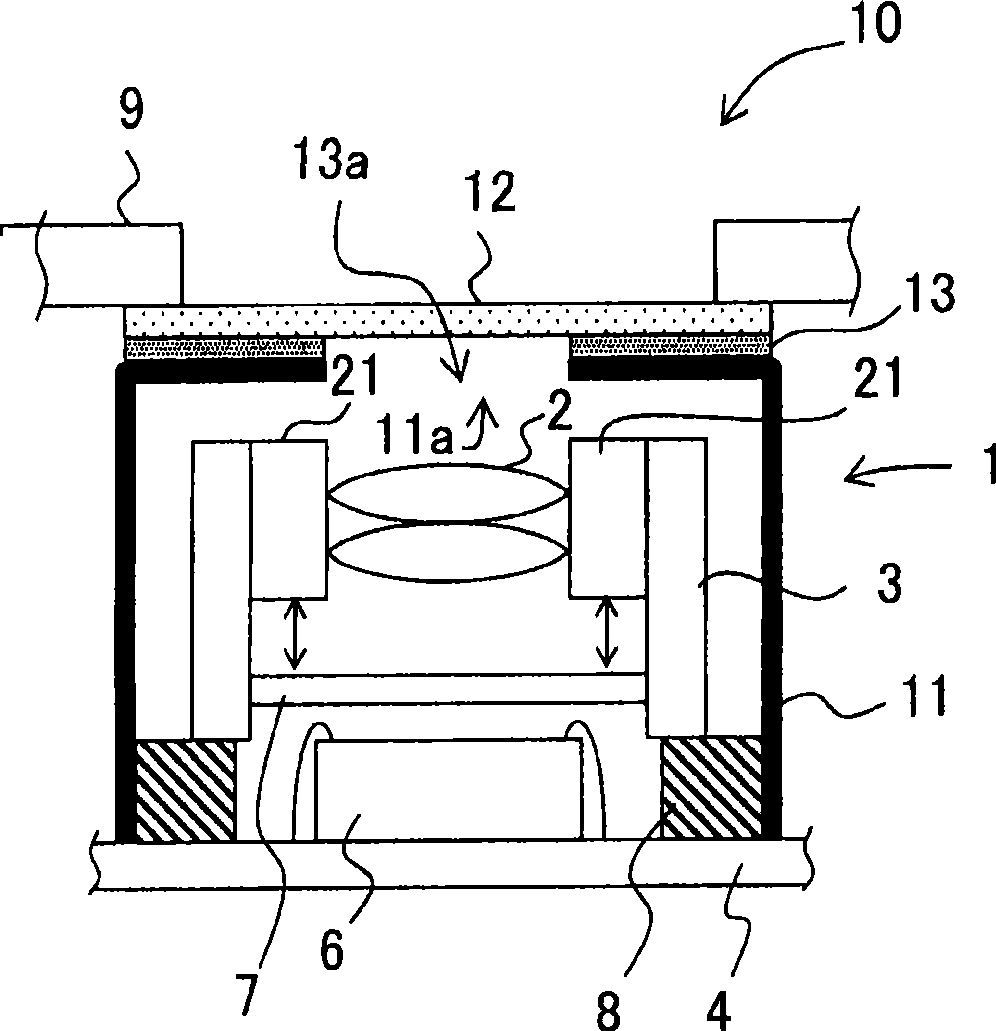

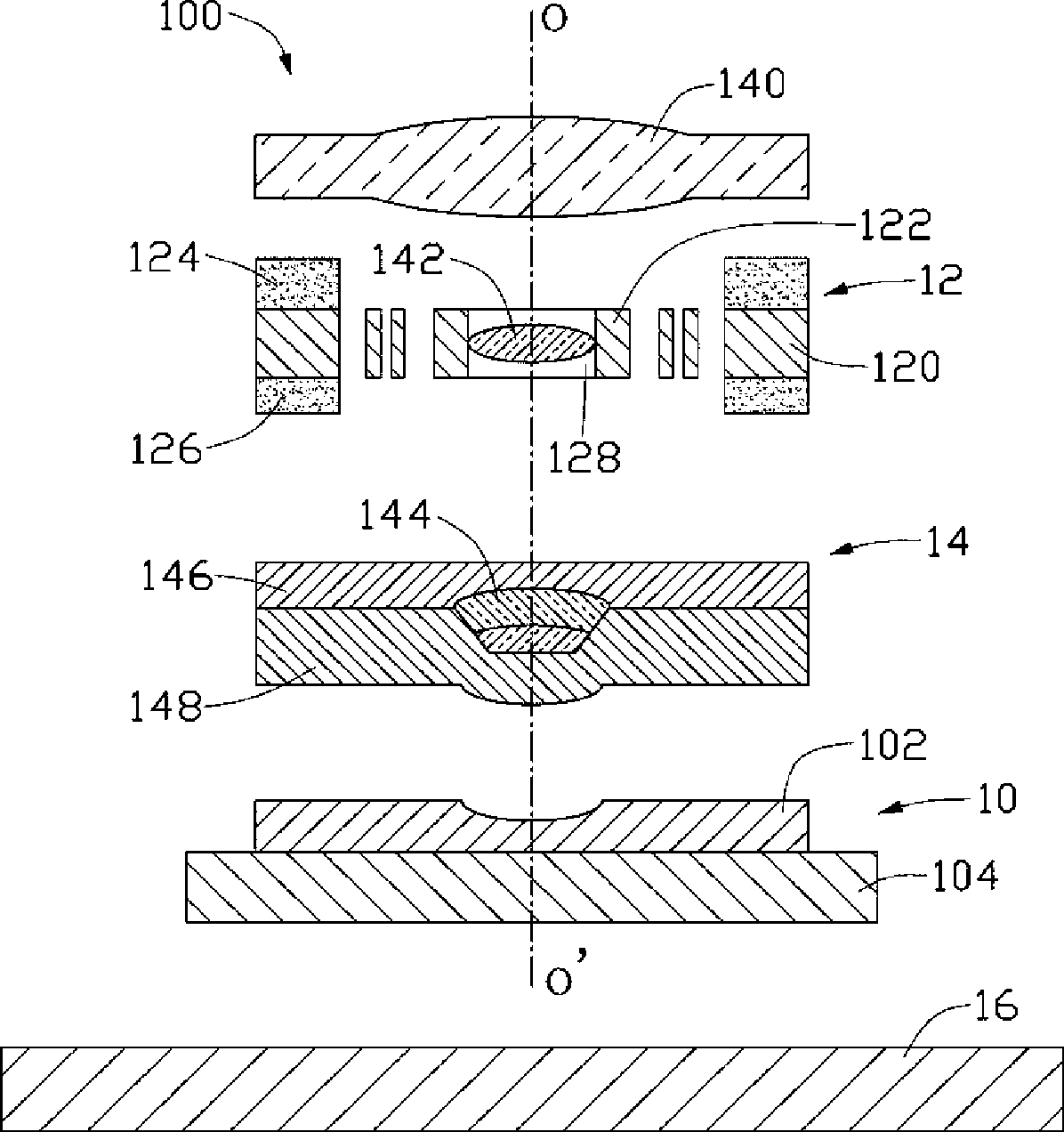

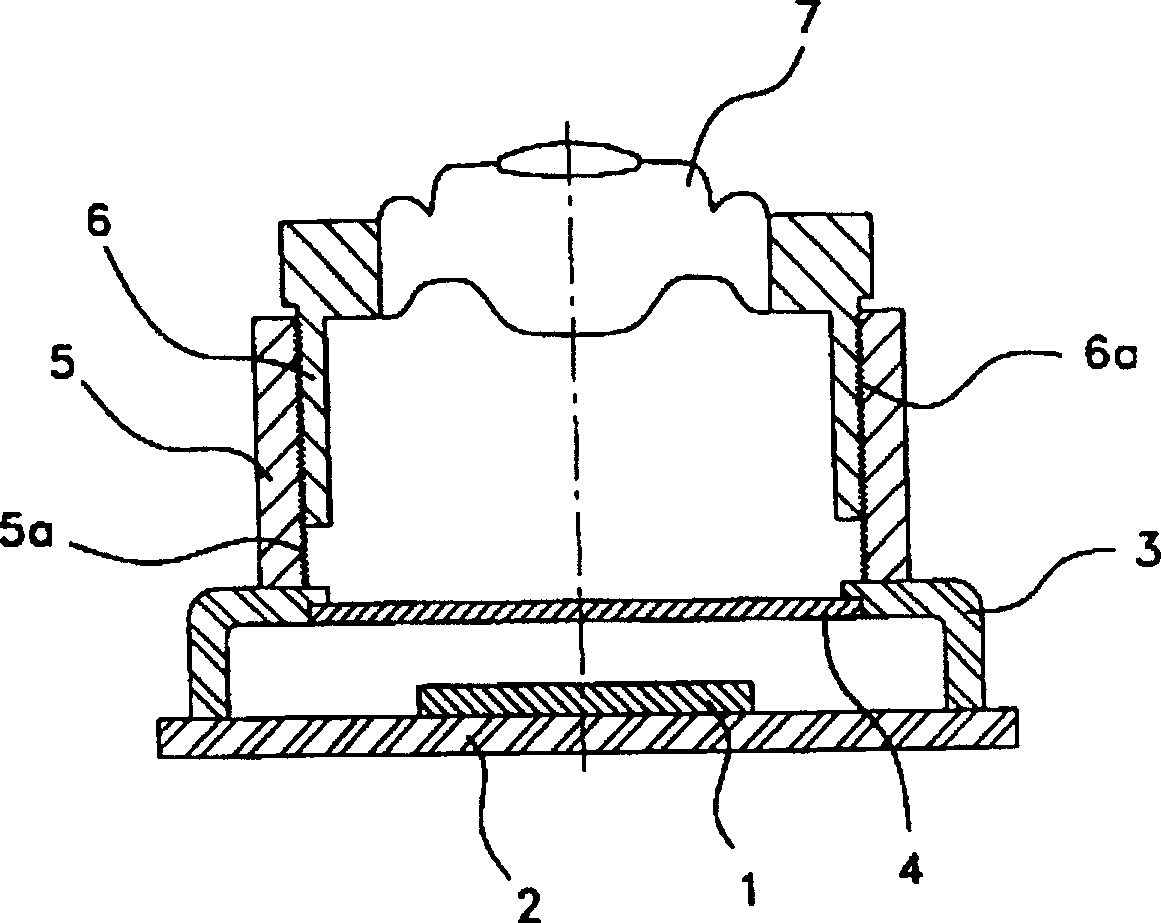

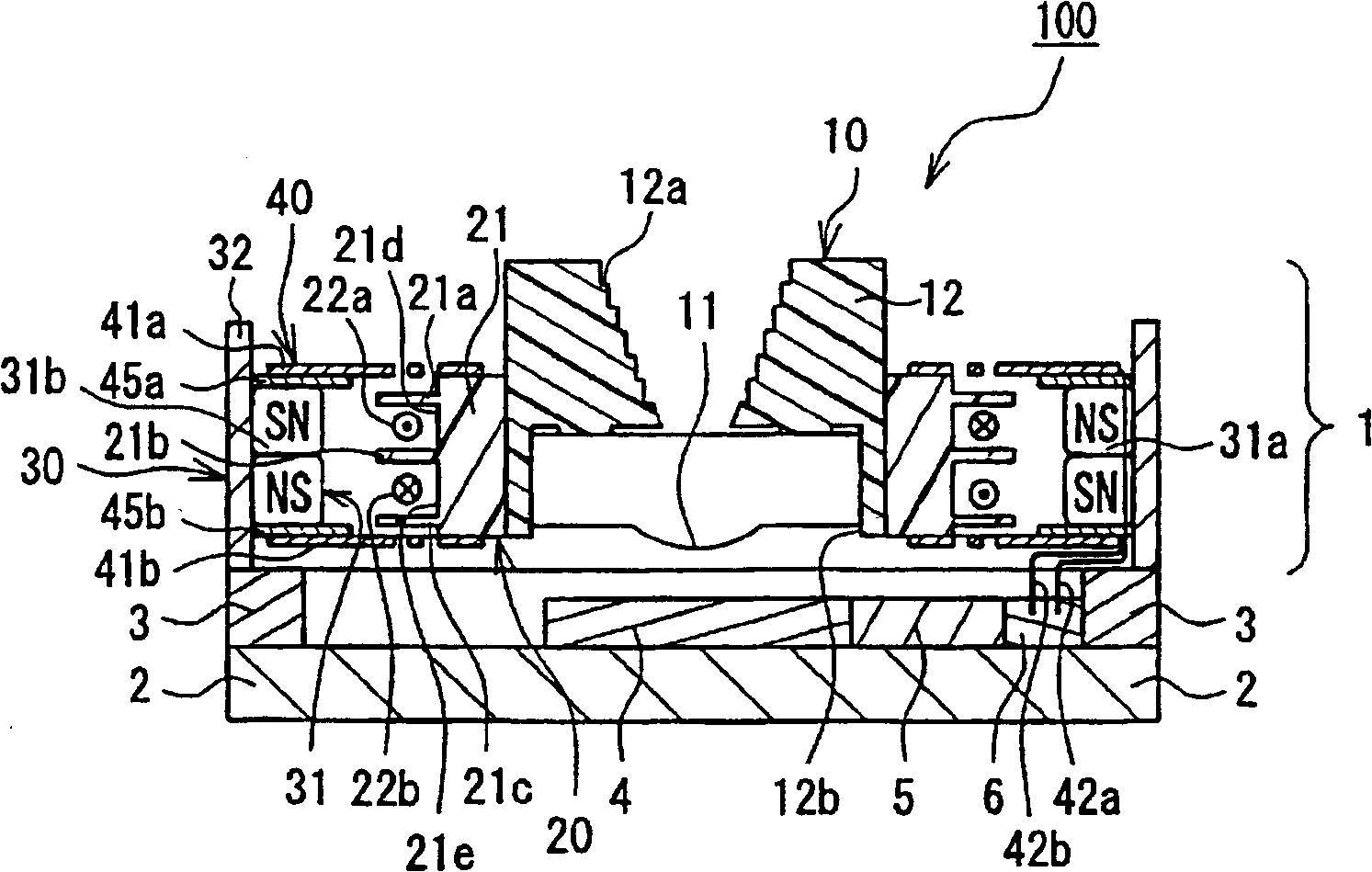

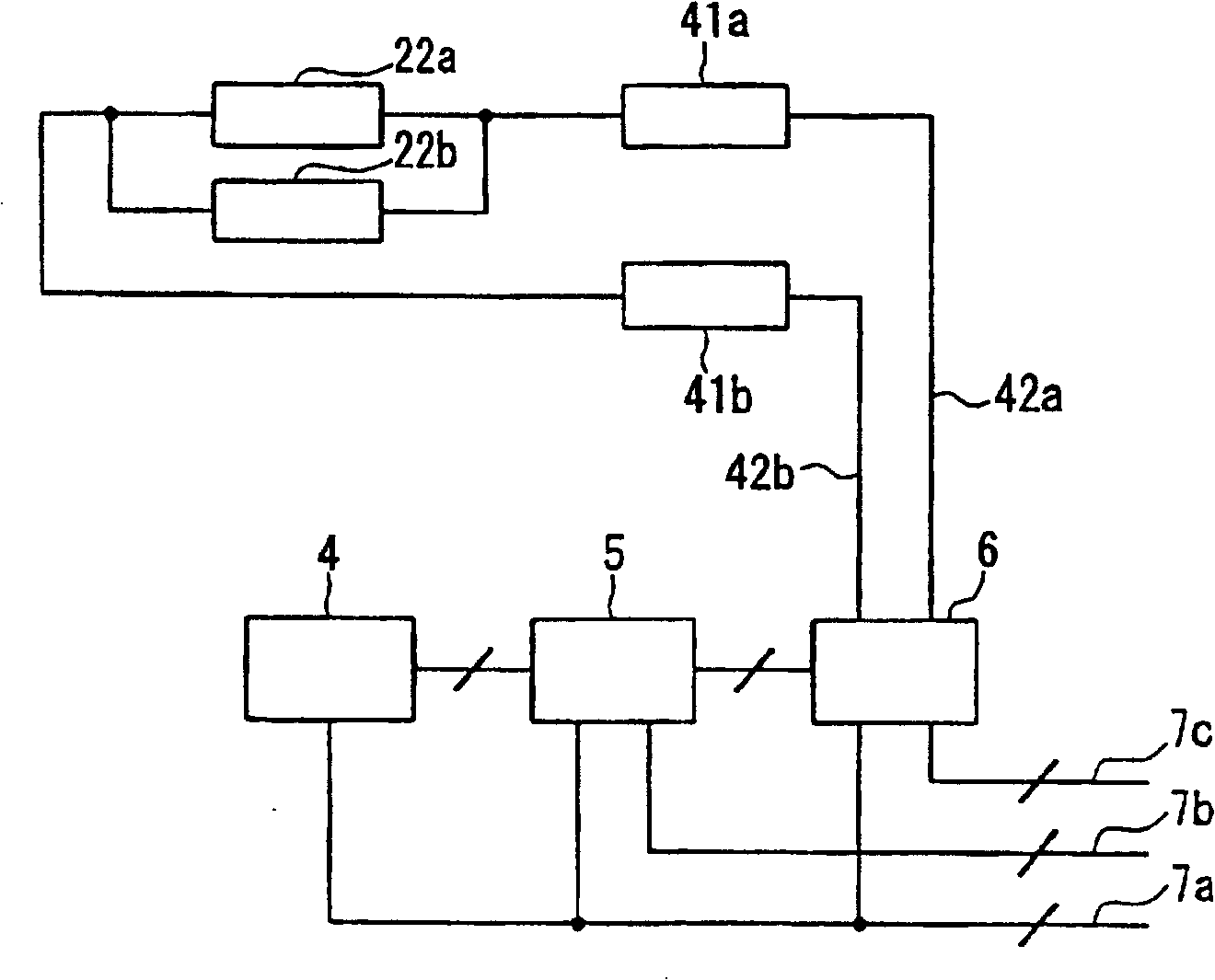

Camera module

InactiveCN1910492AReduce power consumptionWith auto focus functionTelevision system detailsColor television detailsOptical axisComputer module

A camera module has a lens section (10) including at least one lens (11), an imaging element (4) having a light receiving surface substantially perpendicular to the optical axis direction of the lens (11), a fixed section (30) provided on the outer periphery side of the lens section (10), a first elastic body (41a) provided on the opposite side of the imaging element (4) relative to the lens (11) and connecting the lens section (10) and the fixed section (30), and a second elastic body (41b) provided on the imaging element (4) side relative to the lens (11) and connecting the lens section (10) and the fixed section (30). The first elastic body (41a) and the second elastic body (41b) have the same shape, the first elastic body (41a) and the second elastic body (41b) are arranged so as to be opposed to each other with their center axes aligned, and the second elastic body (41b) is placed such that its shape is different from that shape of the first elastic body (41a) which is projected in the optical axis direction of the lens (11).

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

Lens module and digital camera with automatic focusing function

InactiveCN101196600AReduce the use volumeReduce volumeMountingsPiezoelectric/electrostrictive devicesCamera lensOptical axis

The invention relates to a lens module with automatic focus function and digital camera. The lens module comprises a drawtube, a focusing lens system set in the drawtube, at least one actuator mechanical linking with the focusing lens system. Wherein, the at least one actuator comprises at least one electric conduction polymer film with electrostrictive effect, one guide post and two springs on the guide post. The focusing lens system is in slip connection with the guide post and the two springs are set on both sides of the focusing lens system to give two acting force to the focusing lens system in opposite direction. The at least one electric conduction polymer film with electrostrictive effect is equipped on the guide post and between the two springs, the shape of which is changeable after being electrified to drive the focusing lens system move along the direction of the axis. The lens module and the camera is characterized by small volume, light weight and low energy consumption, which can be used in portable electronic equipments like cellphone.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

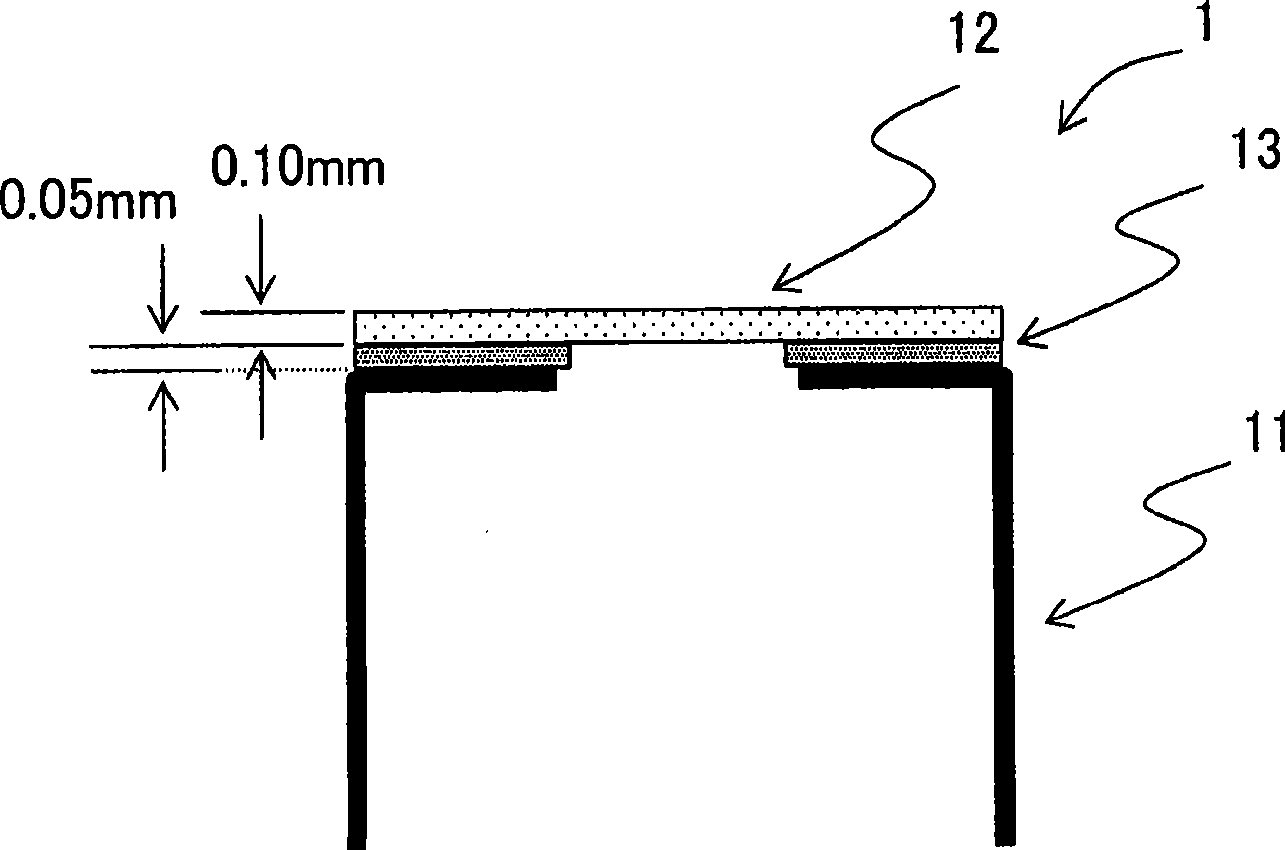

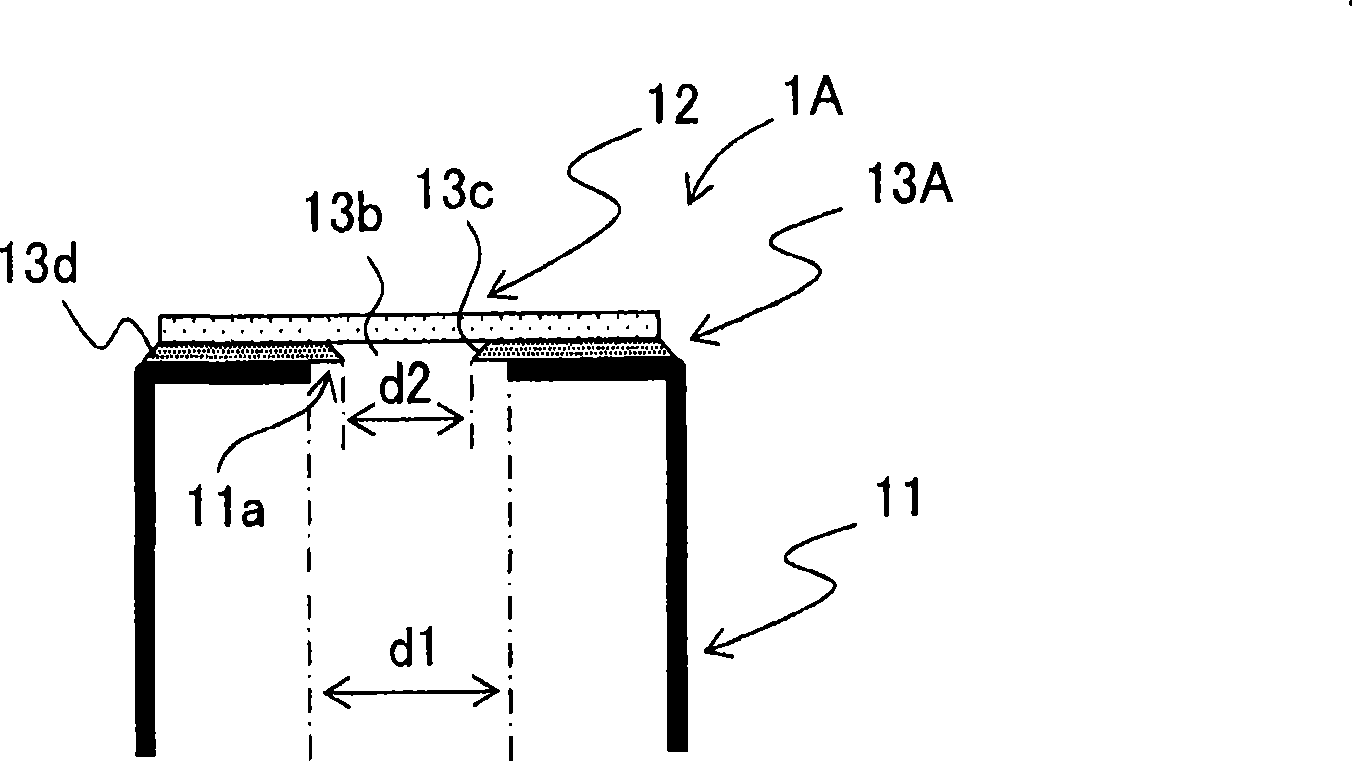

Case member, sensor module, and electronic information device

InactiveCN101419327AAvoid reflectionsWith auto focus functionTelevision system detailsDiffusing elementsComputer moduleOptoelectronics

A case member has a predetermined surface and a sealable inside, where a first circular area for passing light is provided at the center portion of the predetermined surface, a double-sided light shielding sheet, which is provided with a second circular area for passing light at the center, is adhered to the predetermined surface such that the second circular area is positioned in a concentric circle manner to the first circular area, the second circular area having a diameter smaller than the diameter of the first circular area, a transparent dustproof film is adhered on the light shielding sheet.

Owner:SHARP KK

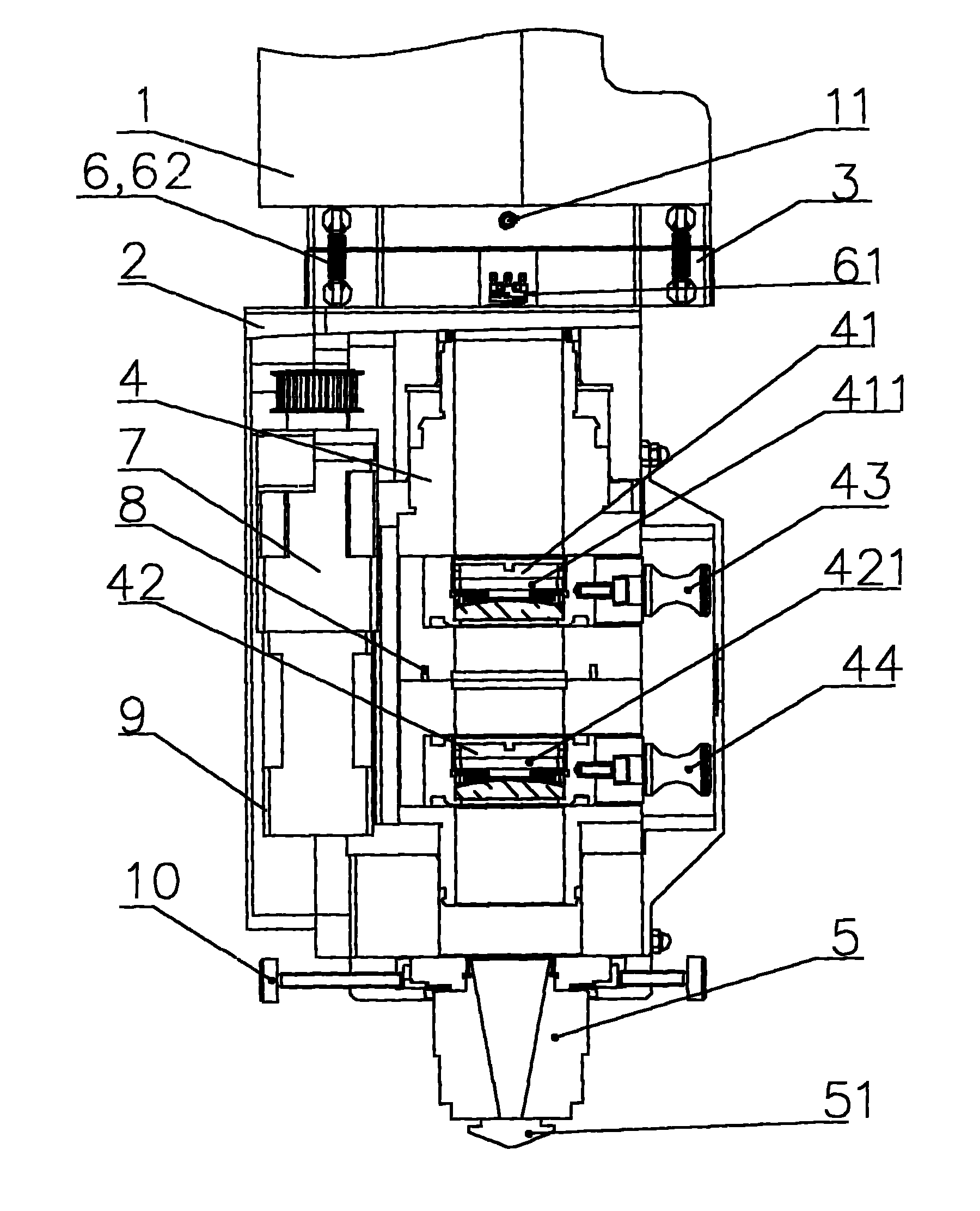

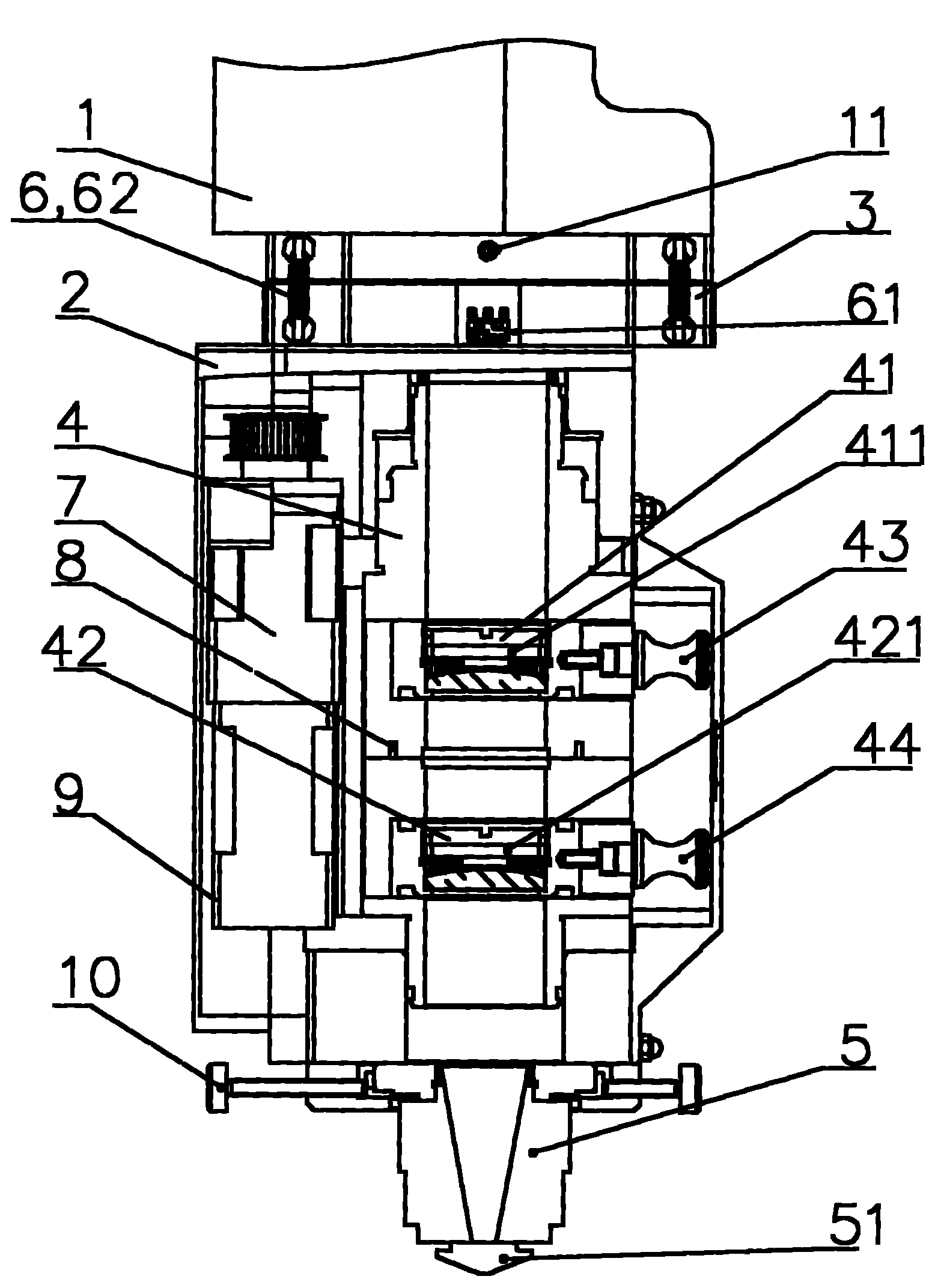

Automatic focusing double-mirror cavity laser cutting head

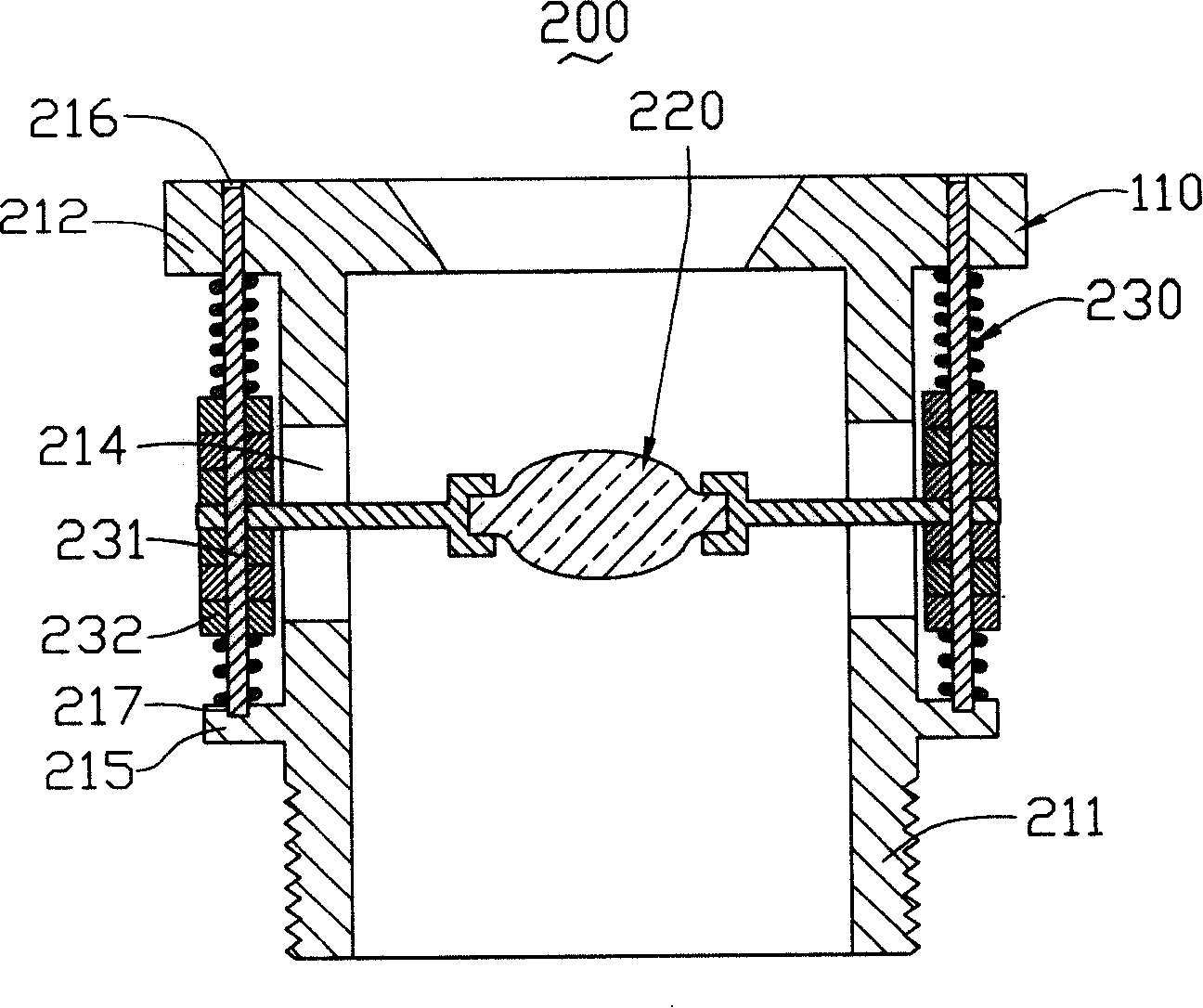

InactiveCN102039490AWith auto focus functionReduce focus adjustment timeLaser beam welding apparatusCapacitanceRadial plane

The invention provides an automatic focusing double-mirror cavity laser cutting head which comprises a base, a connector, a focusing mirror member, a capacitor head and a spray nozzle, and further comprises an anti-bumping mechanism, an automatic focus adjustment mechanism and a water cooling ring. The focusing mirror member comprises a first mirror cavity and a second mirror cavity; the first mirror cavity is internally provided with a first drawer-type mirror base; the second mirror cavity is internally provided with a second drawer-type mirror base; the first drawer-type mirror base is internally provided with a 7.5-inch focusing mirror; and the second drawer-type mirror base is internally provided with a 5-inch focusing mirror. The cutting head is provided with double mirror bases, and the 5-inch focusing mirror or the 7.5-inch focusing mirror can be installed manually. The cutting head has the automatic focusing function, and can program to adjust the position of the focus. The cutting head also has the anti-bumping function, and collision at any angle in a radial plane can be detected, so that halt is executed at once so as to protect the cutting head; after collision is eliminated, the cutting head can automatically return to the original work position to cut continuously; and a water cooling manner is adopted for a lens, thereby effectively prolonging the service life of the lens.

Owner:上海团结普瑞玛激光设备有限公司

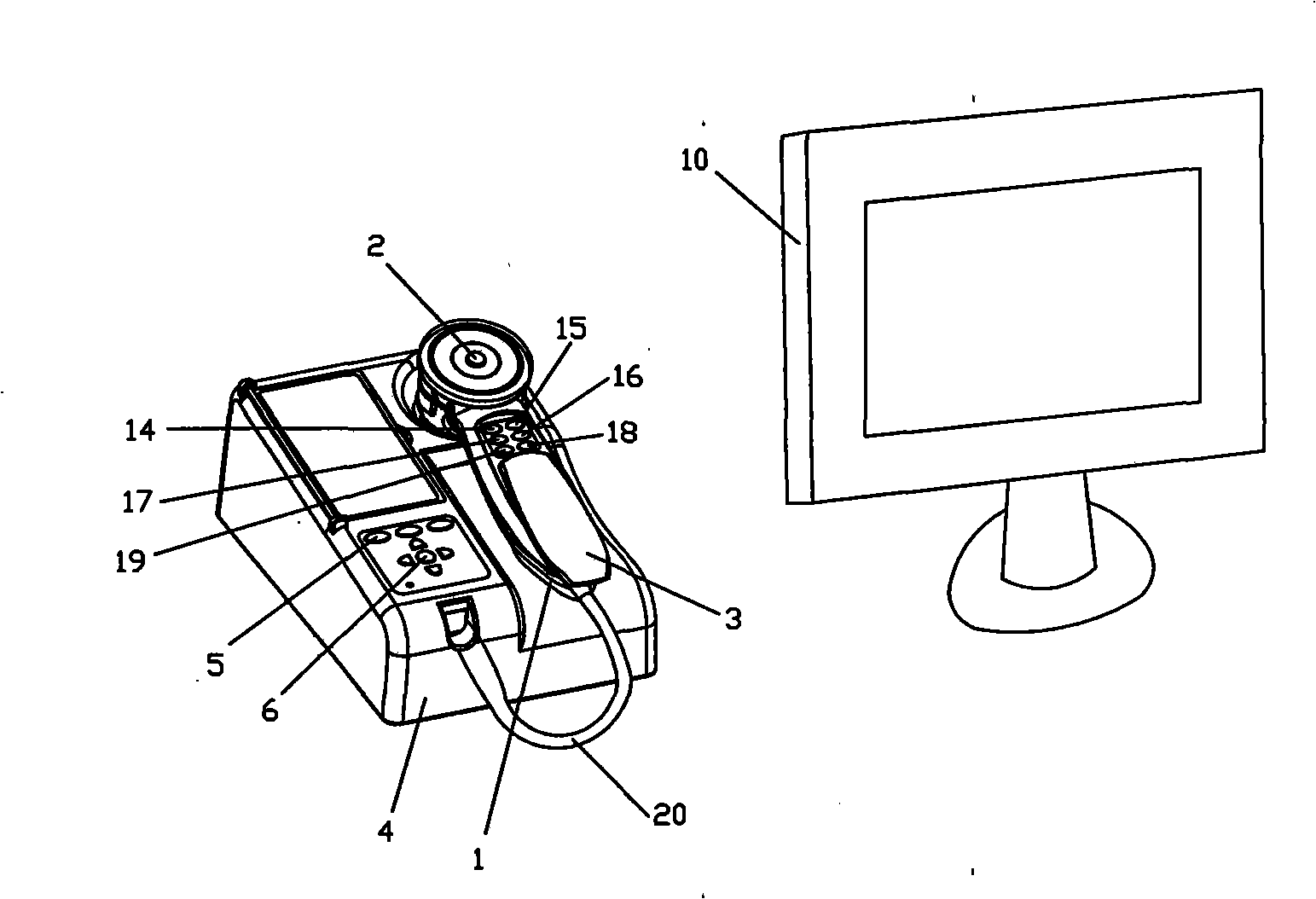

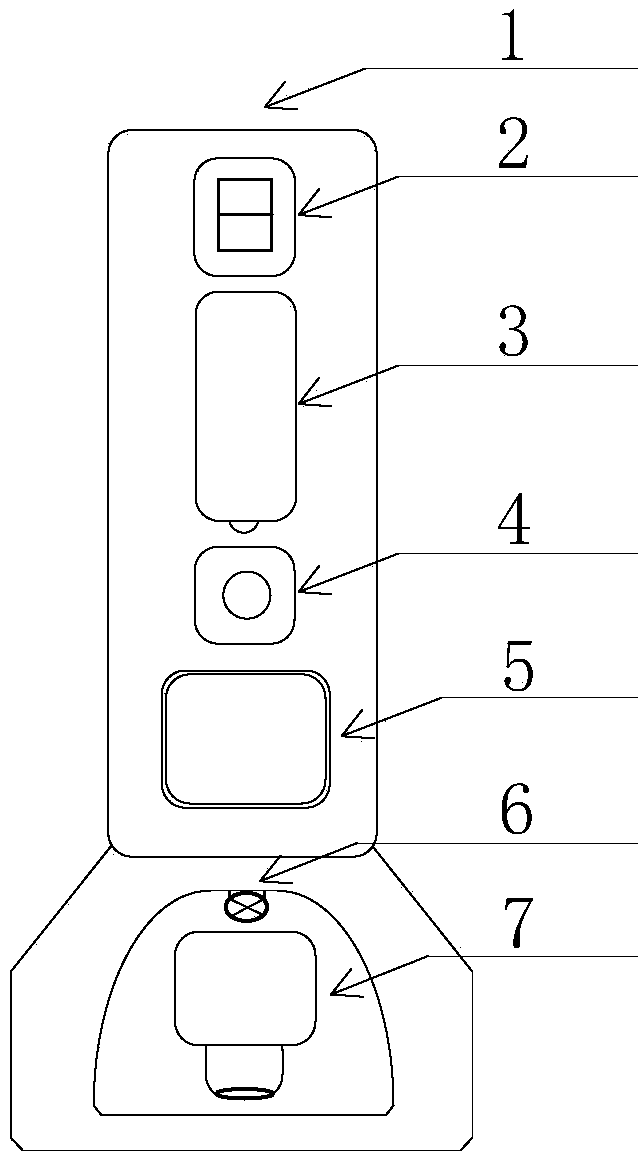

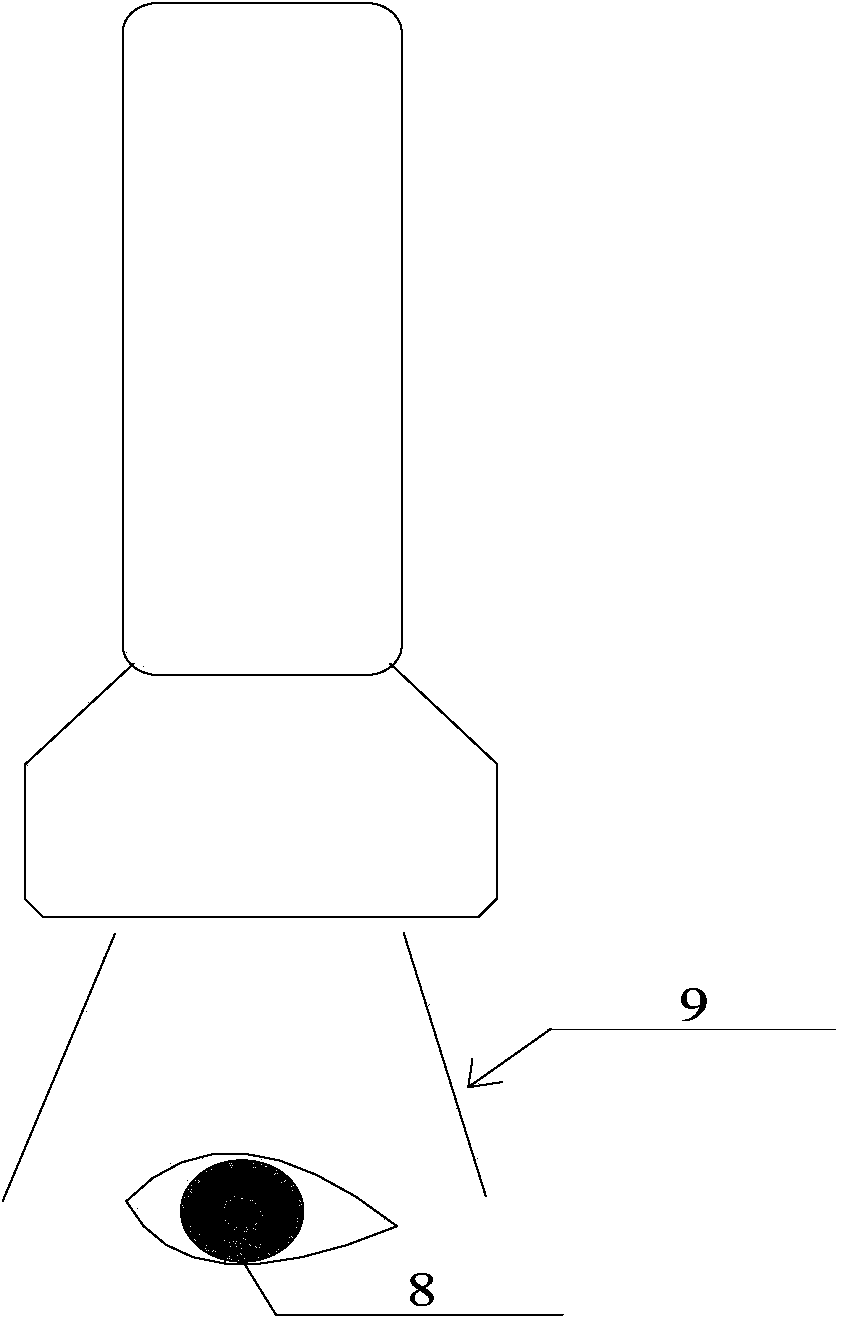

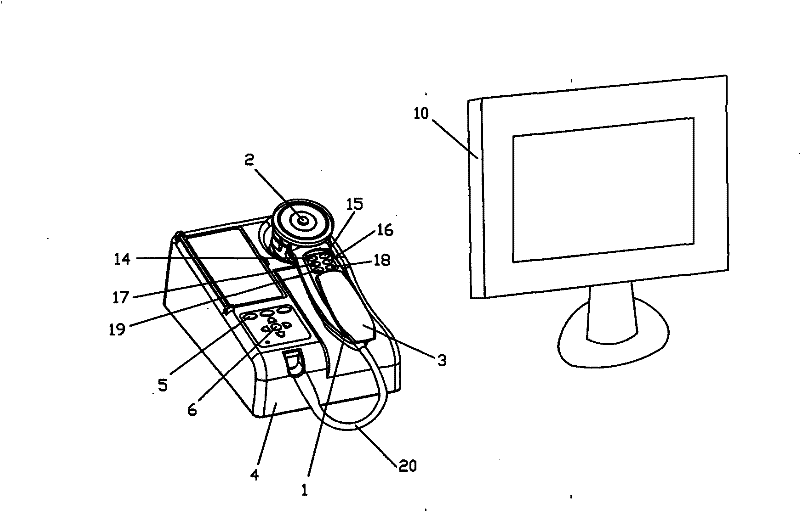

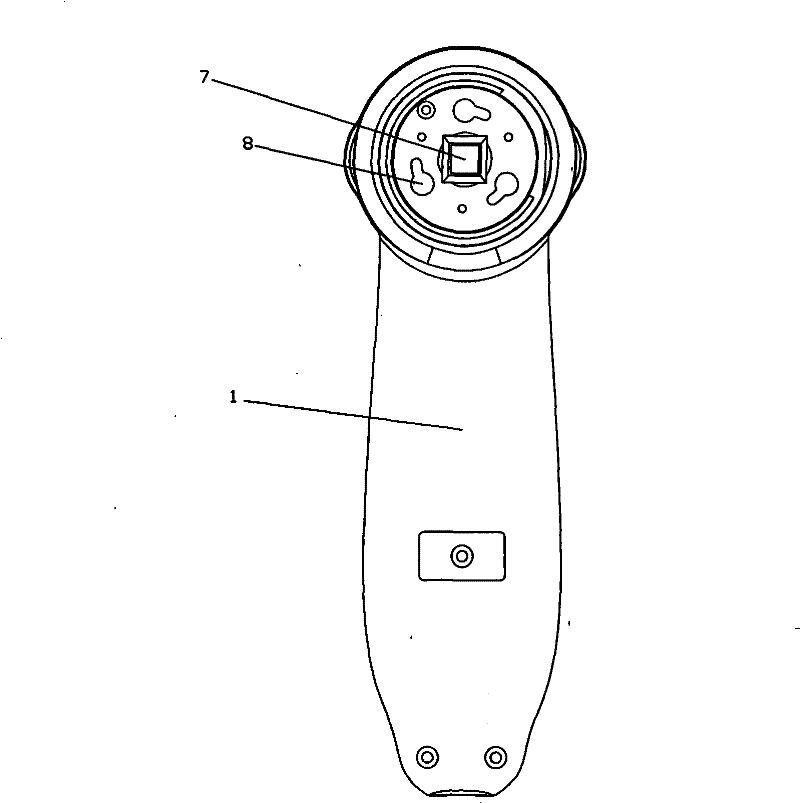

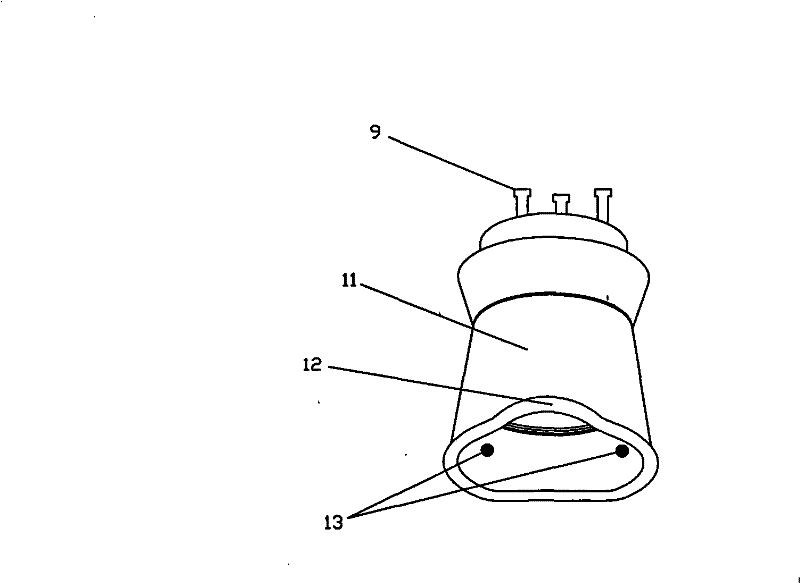

Iris diagnostic device

The invention relates to a diagnostic device and particularly discloses a diagnostic device for scanning the irises of eyes. The diagnostic device comprises a mainframe, a hand-held reader and a display; the diagnostic device is provided with a demountable lens, an above-1.3 megapixel CCD (charge-coupled device), an LED lamp and a storage module which can conveniently shoot sharp images; the shot images can be saved as the computer general image formats, such as JPG, BMP and the like; and then, the results can be automatically analyzed by the computer image comparison technology, particularly, pits, gaps, color spots, lines, density and color variation can be judged from the iris images to obtain the diagnosis result reflecting the change in health conditions. The automatic iris diagnostic device has the advantages that the application is convenient, the collected iris images are sharp, the information is accurate and all-around, the structure is simple, the cost is low, the images can be saved and amplified, and the results can be easily analyzed and judged.

Owner:杨思蕴

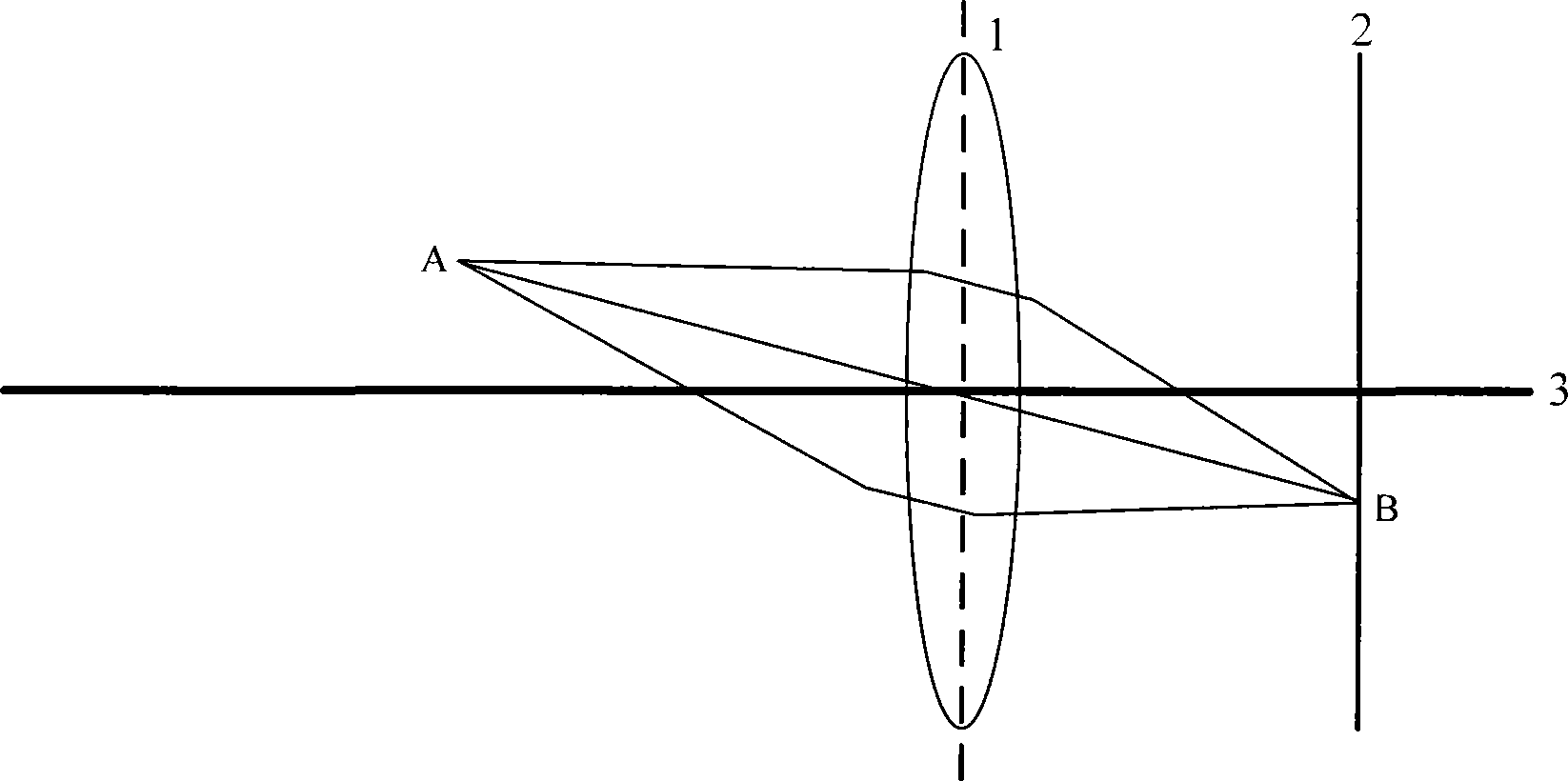

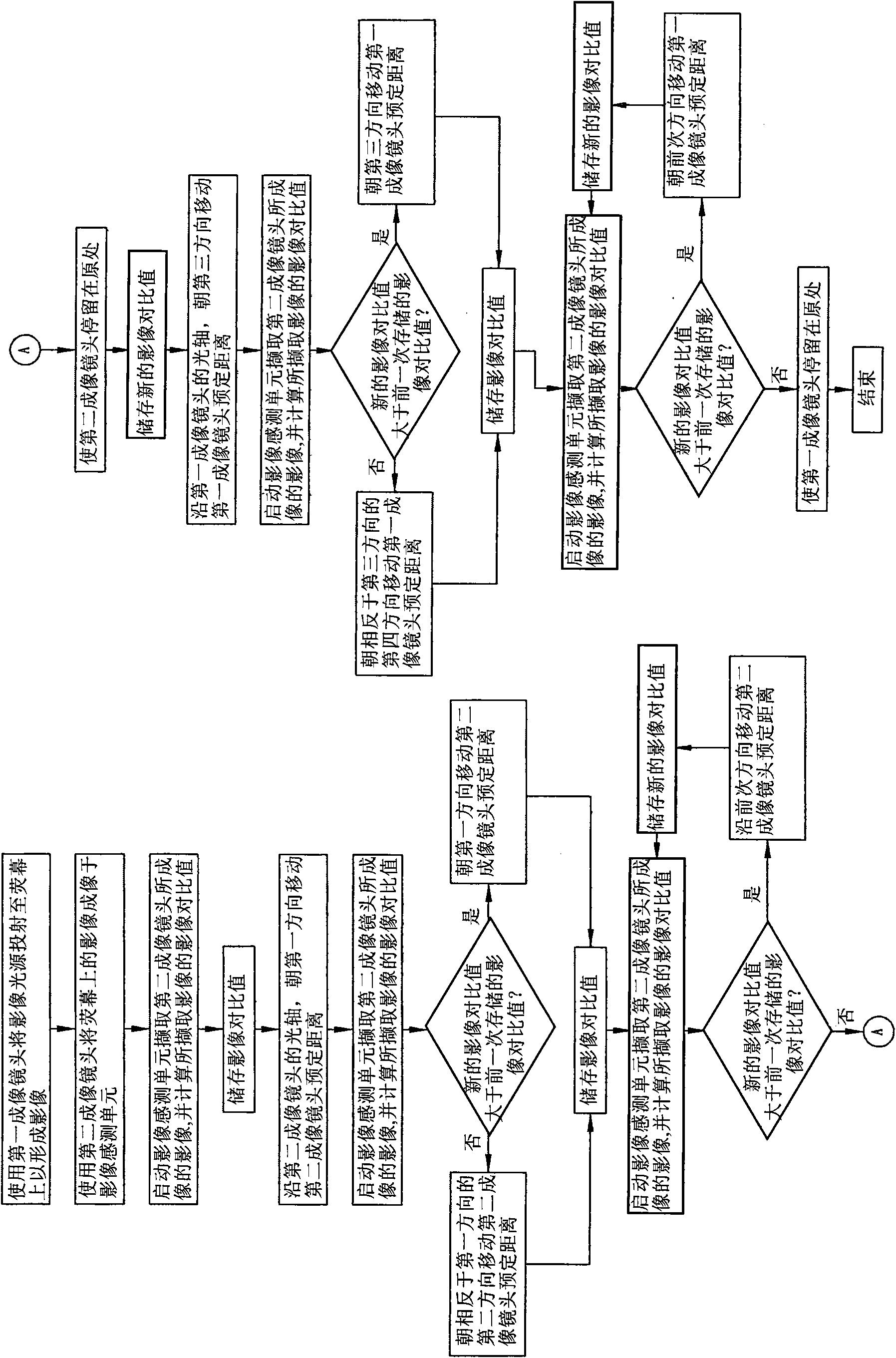

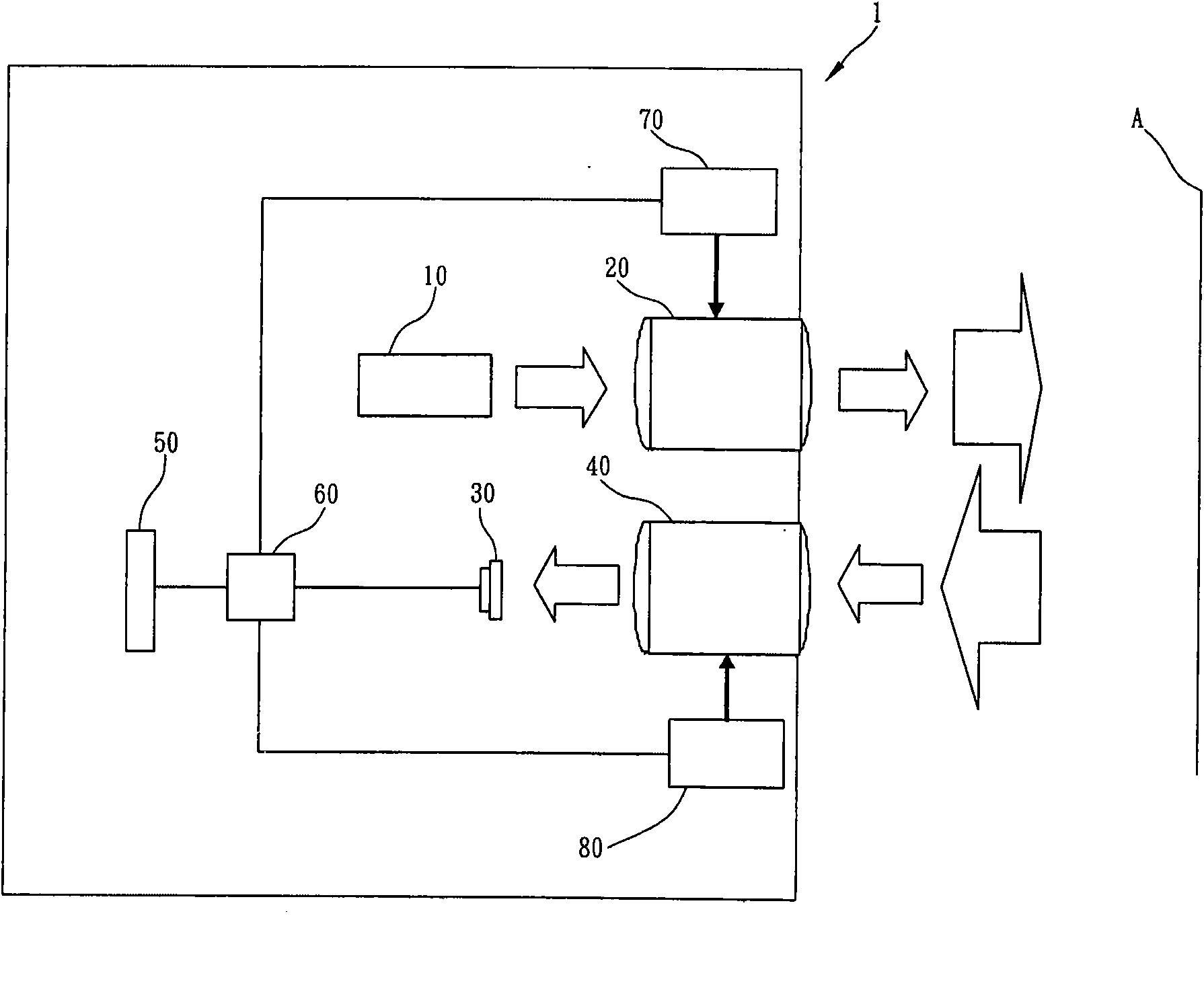

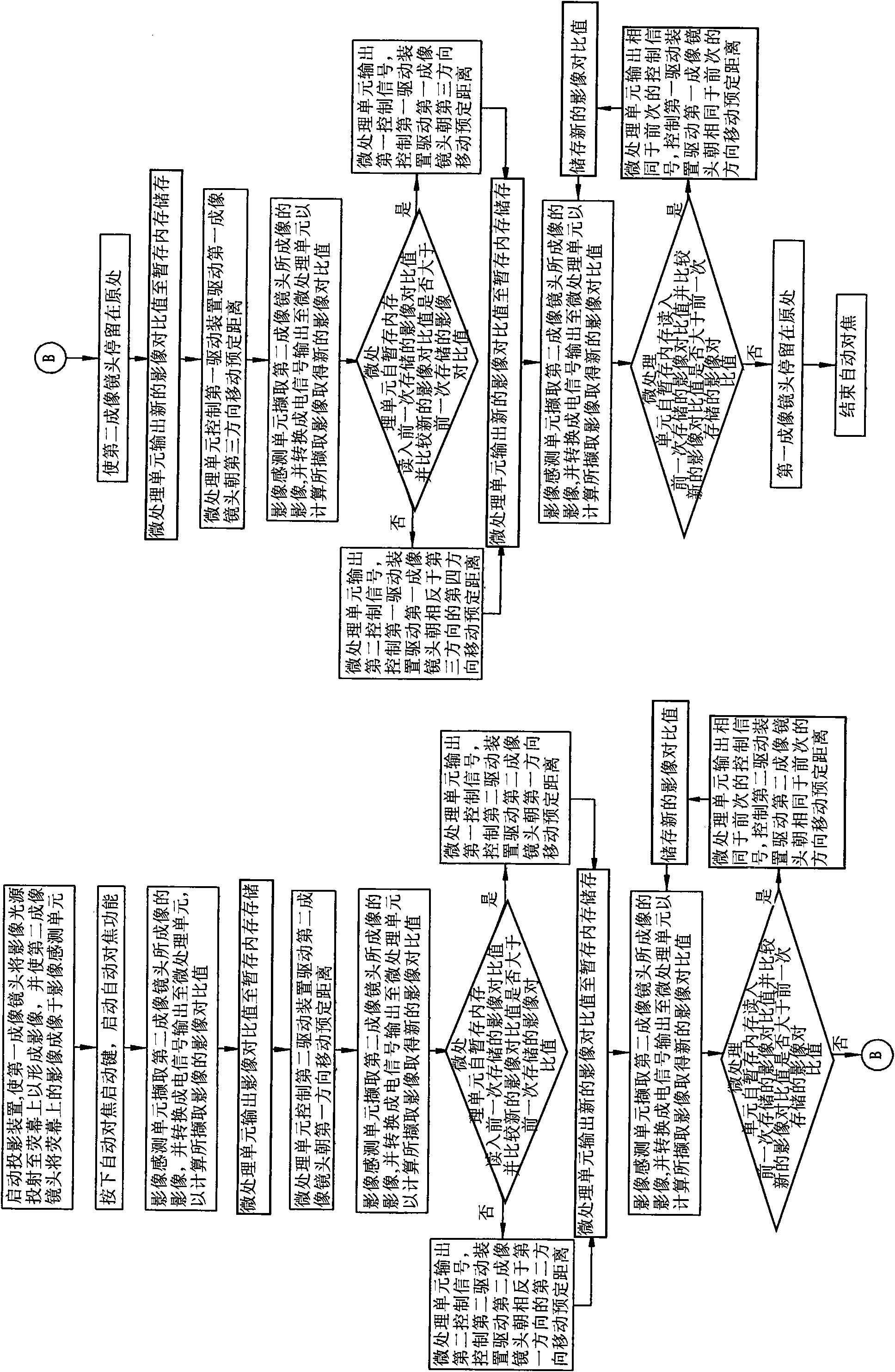

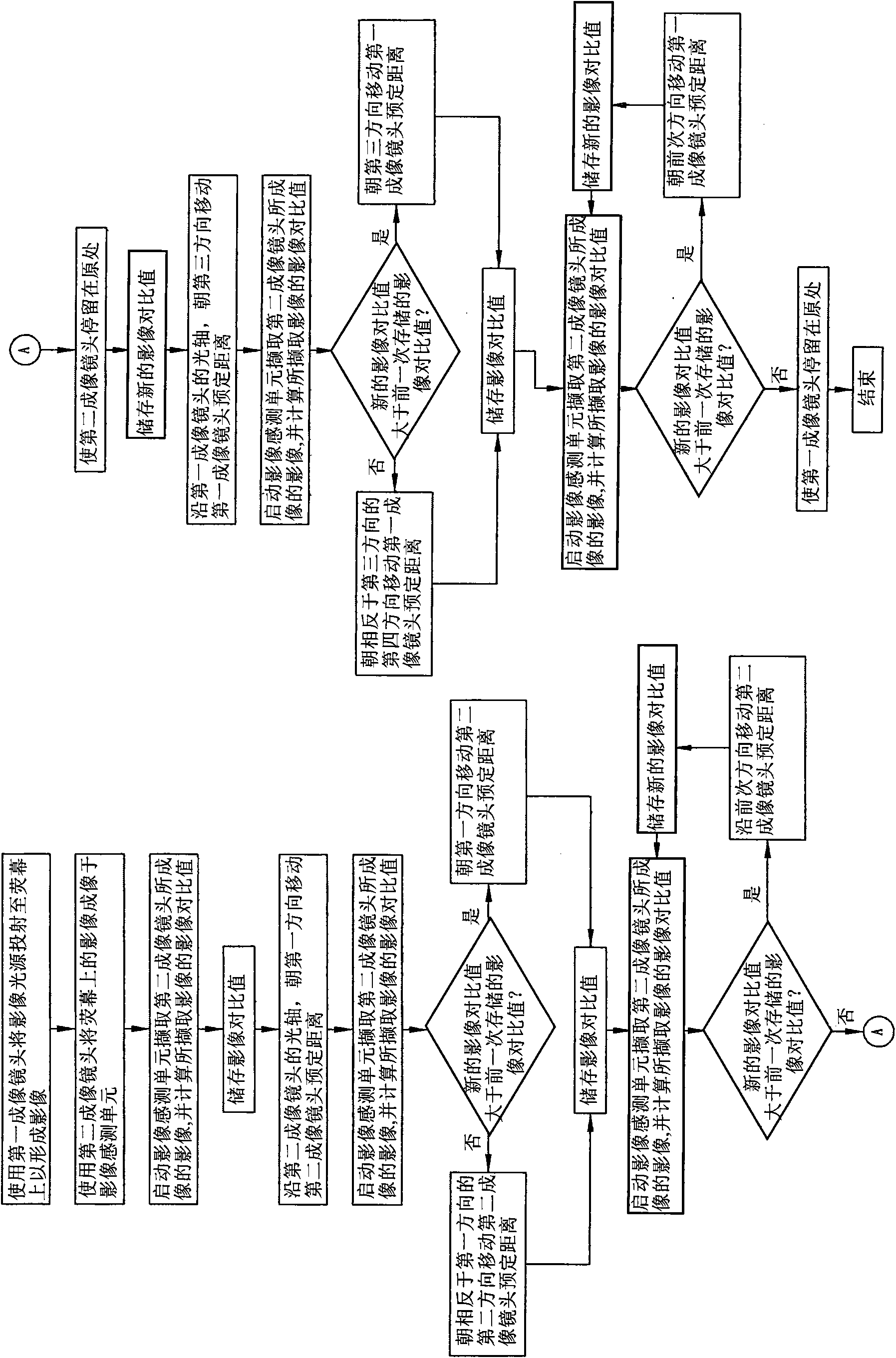

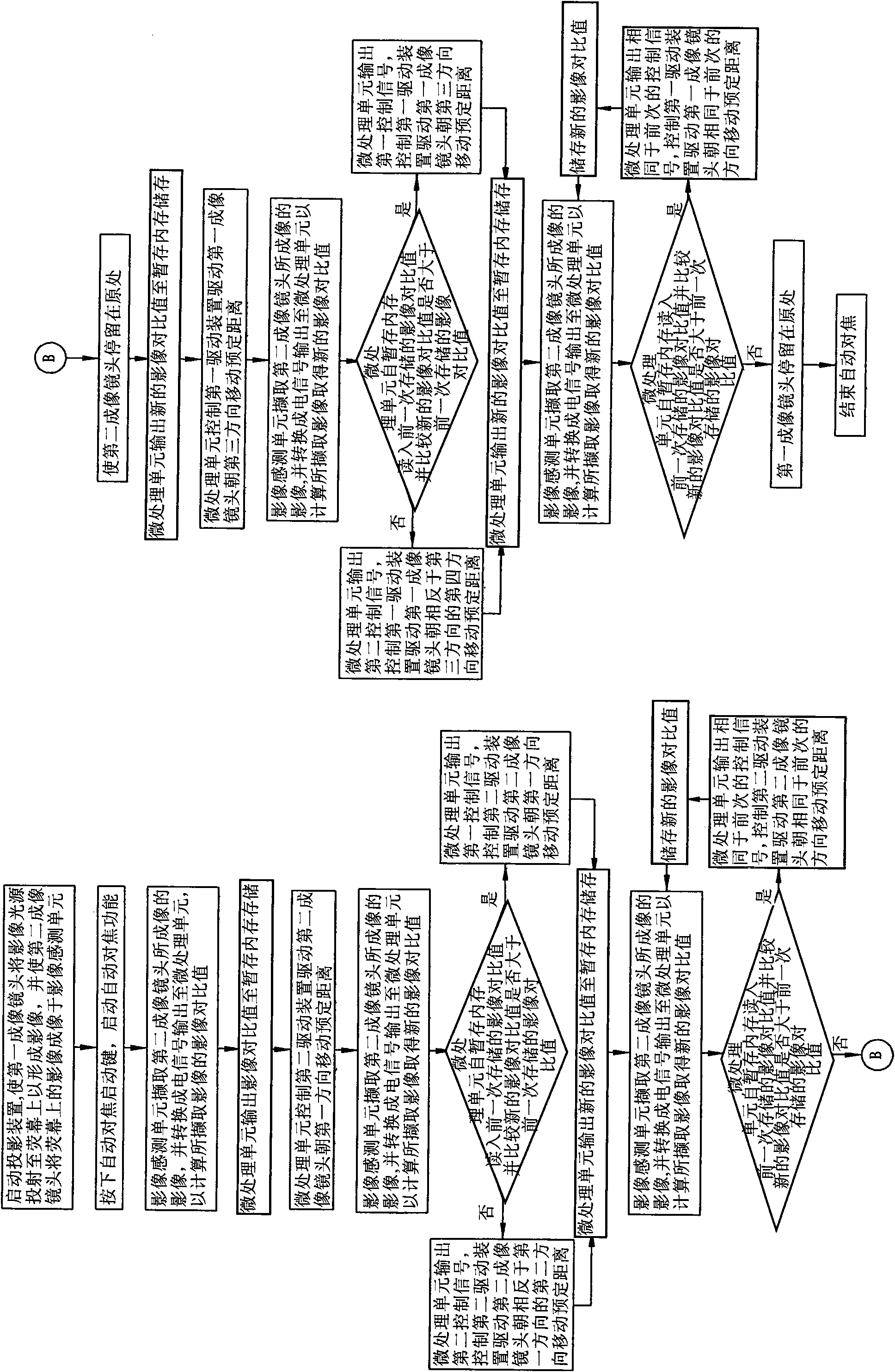

Projection device with automatic focusing function and automatic focusing method thereof

The invention relates to a projection device with an automatic focusing function and an automatic focusing method thereof. The steps are as follows: imaging an image which is projected on a screen by a first imaging lens by utilizing a second imaging lens on an image sensing unit; moving the second imaging lens, stating the image sensing unit to capture an image produced by the second imaging lens each time after the second imaging lens is moved, and calculating the definitions of the captured image; and comparing the definitions and obtain a largest value of all, and the position of the second imaging lens which corresponds to the largest value is a focusing position of the second imaging lens. Sequentially, moving the first imaging lens, each time after the first imaging lens is moved, capturing an image produced by the second imaging lens and calculating the definitions of the images; comparing the definitions of the images so as to obtain the largest value of all, and the positionof the first imaging lens which corresponds to the largest value is a focusing position of the first imaging lens.

Owner:ASIA OPTICAL CO INC

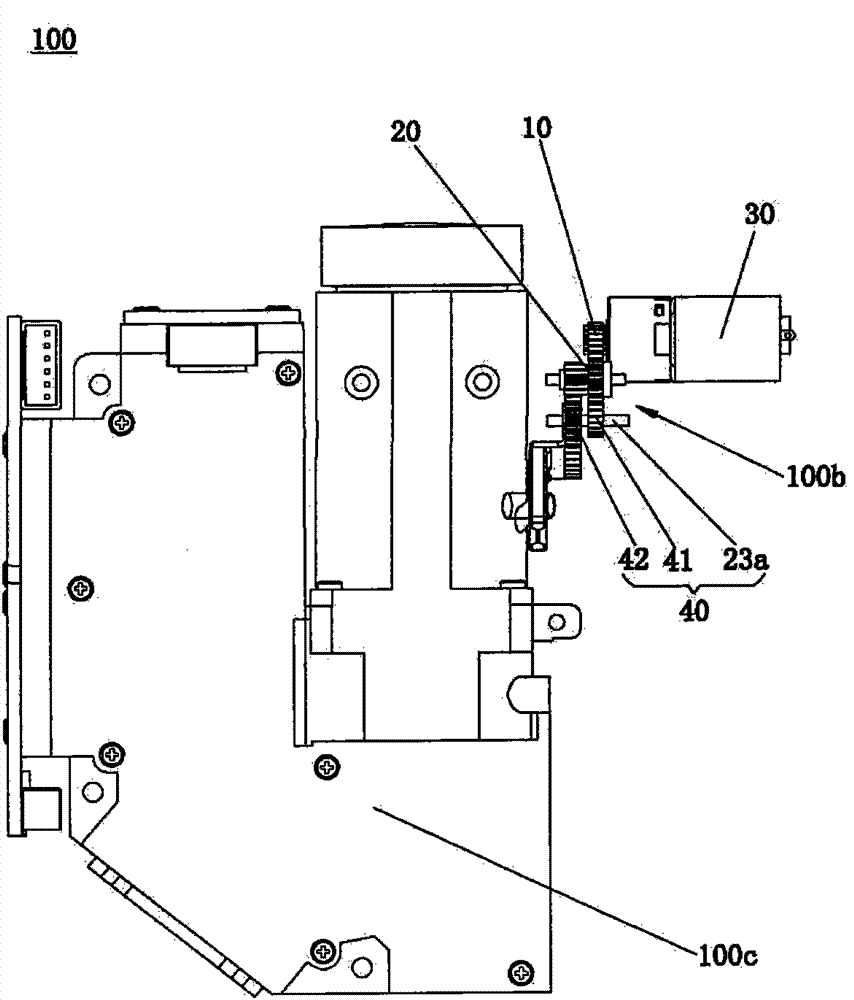

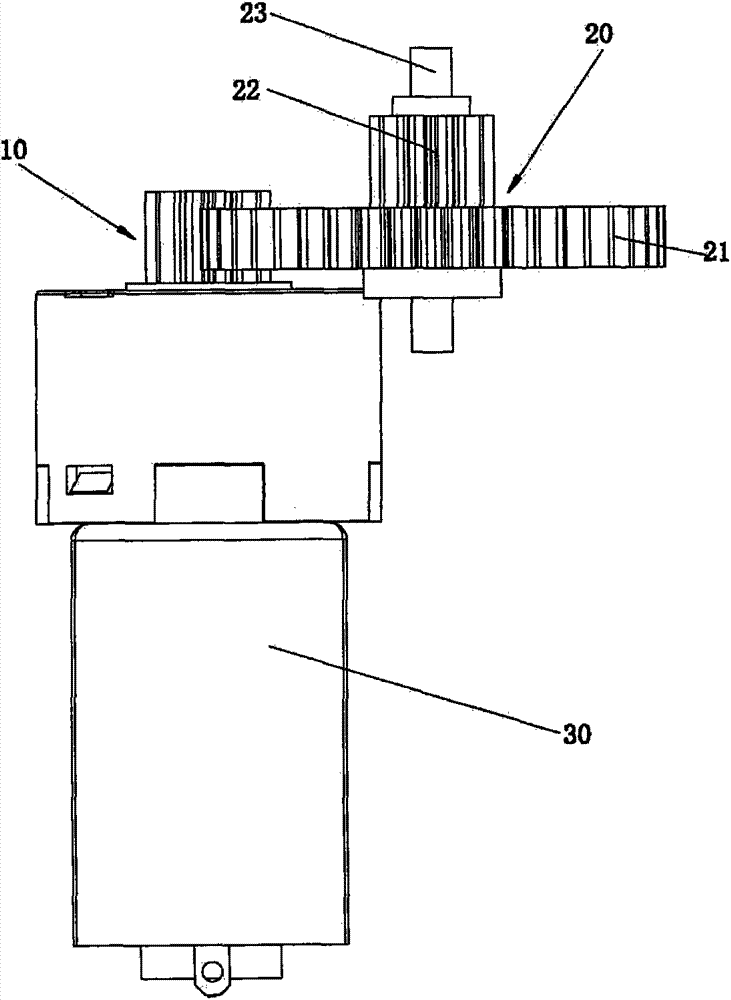

Projector optical machine with automatic focusing function

The invention discloses a projector optical machine with the automatic focusing function. The projector optical machine with the automatic focusing function comprises a focusing motor gear assembly, an optical machine body and a main control system. The focusing motor gear assembly comprises a drive gear, a first driven gear assembly, a second driven gear assembly and a motor driving the drive gear to rotate. The drive gear drives the first driven gear assembly and the second driven gear assembly to rotate, and comprises a first gear tooth part and a shaft sleeve integrated with the first gear tooth part. An output shaft of the motor penetrates through a shaft hole of the drive gear from one side where the shaft sleeve is located, then the output shaft of the motor is connected and installed with the drive gear, the outer diameter of the shaft sleeve is 3.6mm, the length of the first gear tooth part is 2.7mm and the outer diameter of the motor is 10mm. The optical machine body is used for installation of the focusing motor gear assembly. The main control system is electrically connected with the motor and used for controlling the motor to rotate to carry out focusing on the optical machine body. The projector optical machine with the automatic focusing function can achieve the automatic focusing function, and is convenient and fast to use, and safe.

Owner:HOTUS TECH CO LTD

Camera module group

The invention relates to a camera module which comprises a circuit wafer, an image sensor and a lens module. The lens module comprises a first optical lens and an actuator; wherein, the actuator comprises a fixing part and a movement part; the movement part is provided with a through hole in which the first optical lens is embedded. The fixing part, the movement part and the image sensor are connected electrically. Rays transmits the lens module and is imagined on the image sensor. When the camera module electrifies the circuit wafer, the actuator drives the first optical lens which is embedded in the movement part to move along the central shaft of the camera module to carry out automatic focusing, thus realizing the function of being used on a portable electronic device and automatic focusing.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

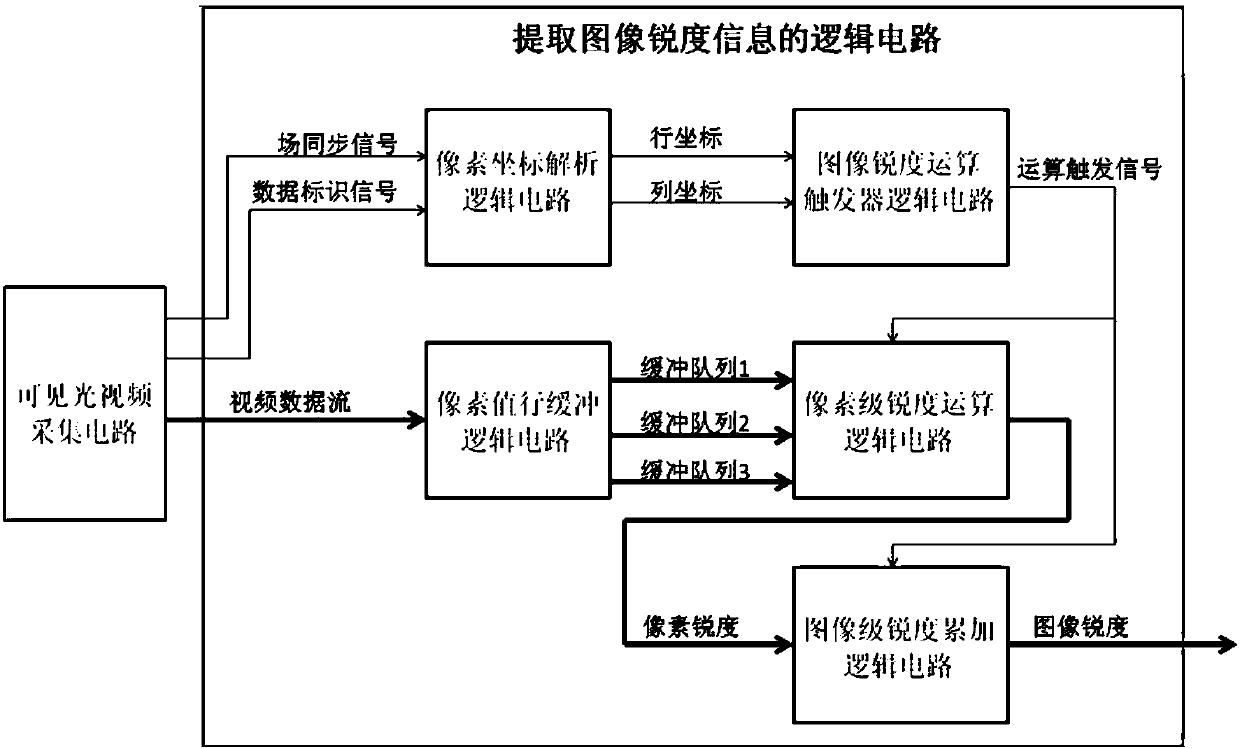

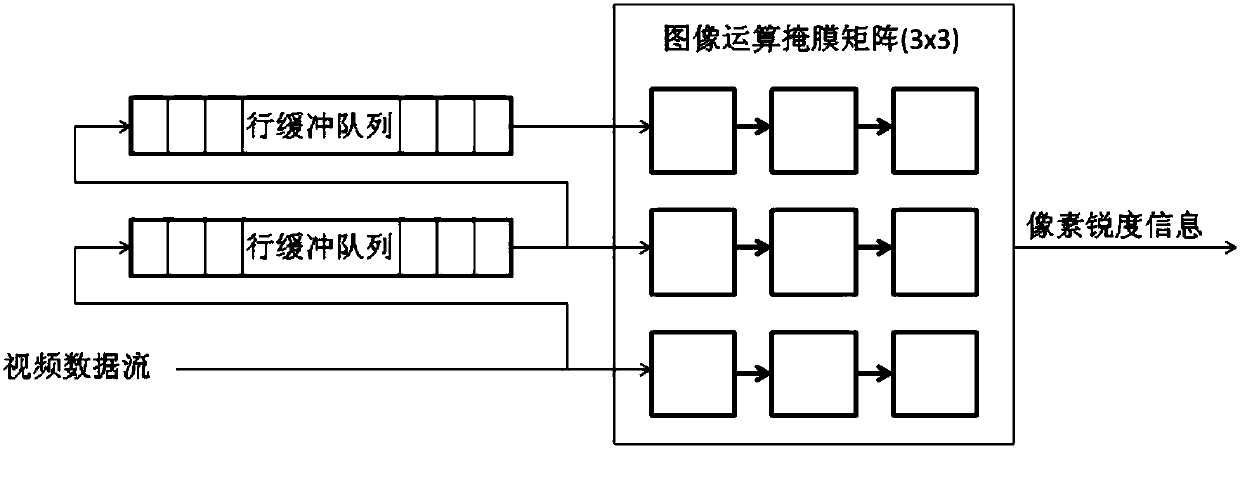

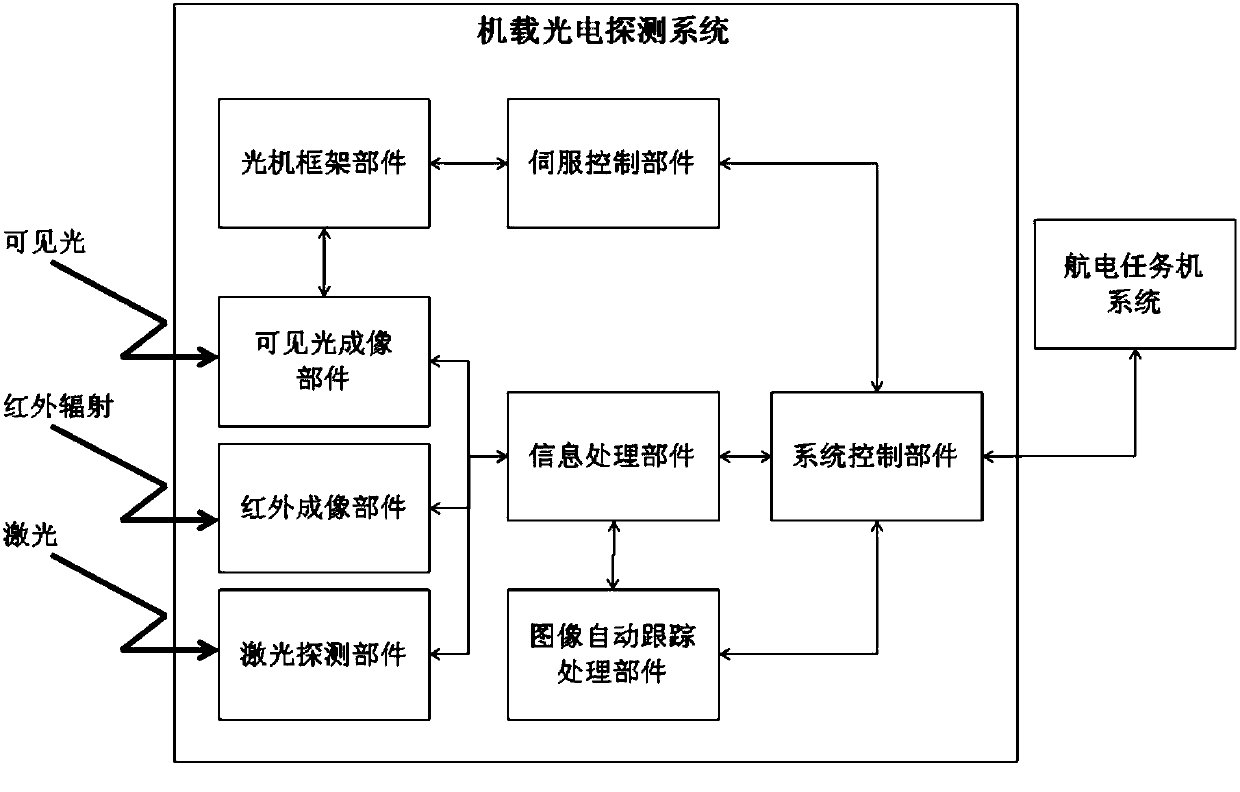

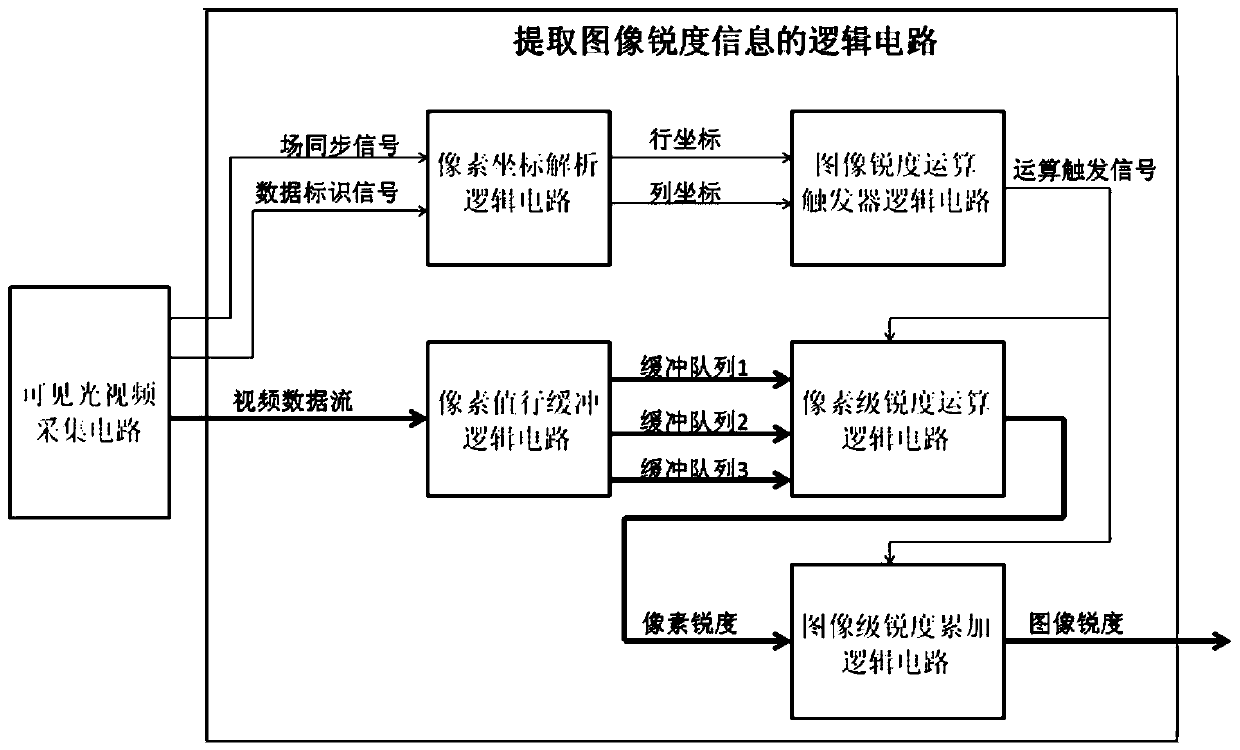

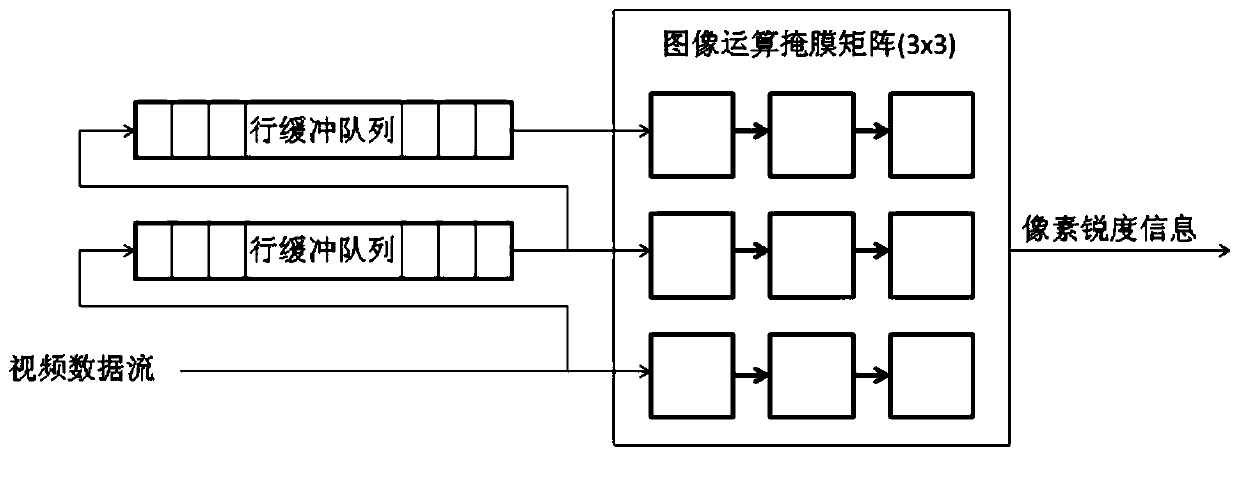

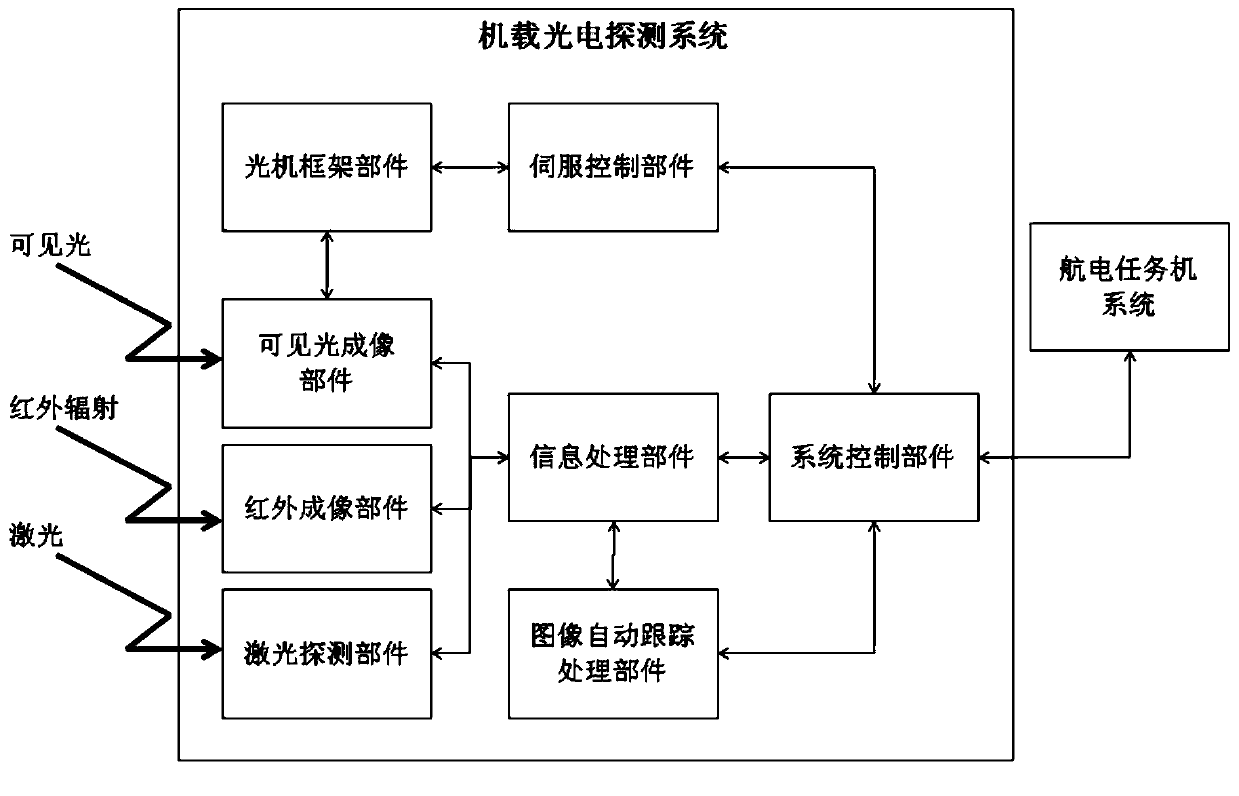

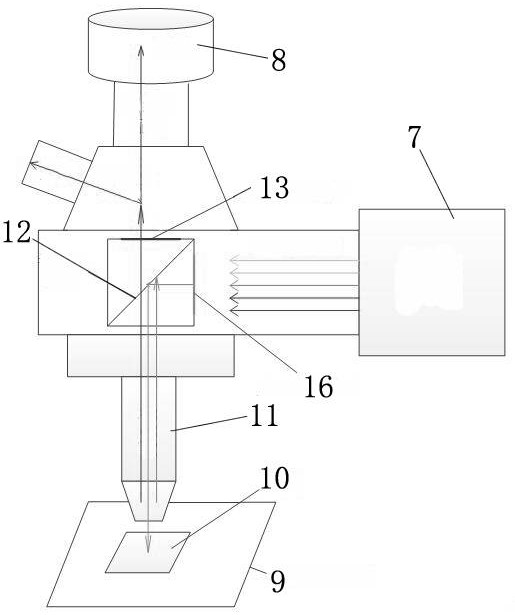

Logic circuit for zero-relay extraction of image sharpness information in assembly line mode and extraction method

ActiveCN107911605AReal-timeAchieve one-key focusTelevision system detailsColor television detailsImaging qualityAssembly line

The invention relates to a logic circuit for zero-relay extraction of image sharpness information in an assembly line mode and an extraction method. A field programmable gate array (FPGA) is adopted as a hardware implementation platform for image processing, and the logic circuit is divided into five parts, namely a pixel coordinate analysis logic circuit, a pixel value line buffer logic circuit,an image sharpness operation trigger logic circuit, a pixel-level sharpness calculation logic circuit and an image-level sharpness accumulation logic circuit. Time sequence signals superimposed on a high-definition video source are used, and a coordinate index value of an image pixel is reconstructed in real time for follow-up trigger control logic; through a multi-channel buffer queue mode, imagedata is grouped again, so that subsequent processing is streamlined. The logic circuit and the extraction method have the beneficial effects that the image sharpness information can be acquired by the airborne photoelectric detection system, and the airborne photoelectric detection system has a precondition of an automatic focusing function. The imaging quality, the intelligent level and the integration degree of visible light imaging components are improved.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

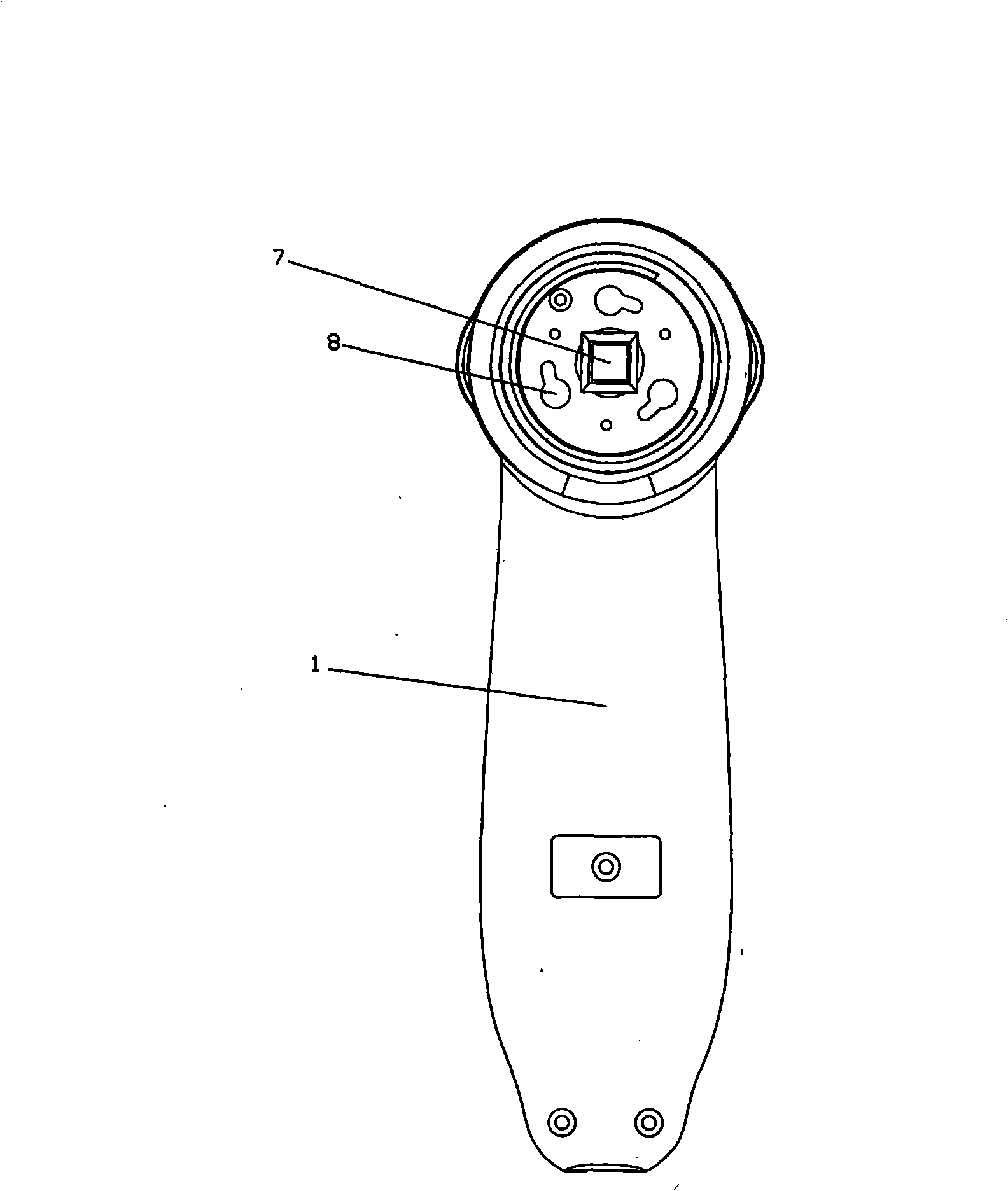

Portable pupil response sensitivity testing device

InactiveCN104068824AVital signs are obviousReduce volumeEye diagnosticsPupil diameterResponse sensitivity

The invention discloses a portable pupil response sensitivity testing device which comprises a high-brightness light-emitting diode (LED) lamp, a charge coupled device (CCD) camera, a microprocessor, a casing, a digital tube, a battery and a switch. The device adopts the CCD camera which is aligned to the eye of a patient, the microprocessor collects a frame of image data through a decoding chip, and the pupil diameter can be obtained through calculation. The microprocessor controls turning on of the high-brightness LED lamp through input and output pins to stimulate the pupil of the patient and collect the other frame of image of the pupil, the diameter of the pupil stimulated by intense light is obtained through the same calculation. The larger the specific value of the two diameters is, the more sensitively the patient responses, the more obvious the life sign is. The specific value of the two diameters is subjected to four-grade division and displayed on the digital tube, so that a doctor can visually judge the illness degree and change of the patient. The device can achieve automatic patient pupil response sensitivity testing, and is safe and convenient to use, high in accuracy and capable of effectively overcoming the shortcomings of visual inspection conducted by the doctor by experience at present.

Owner:荔志云 +1

Laser obstacle clearing instrument collimating lens with automatic focusing function

The invention relates to a laser obstacle clearing instrument collimating lens with an automatic focusing function. The collimating lens comprises a focusing lens bin, wherein a focusing lens driven by an electric focusing device to move back and forth in the focusing lens bin is arranged in the focusing lens bin; the rear end of the focusing lens bin is connected with the front end of the lens cone, and the QBH laser collimating head is installed at the rear end of the lens cone; the electric focusing device is connected and controlled by an operation processing unit, and the operation processing unit is further connected with a distance measuring module used for measuring the distance between an obstacle needing to be removed and the focusing lens. In the actual use process, a user adjusts the optimal focal length according to the distance of the actual obstacle so as to obtain the optimal obstacle removing effect.

Owner:SHANGHAI XIBANG ELECTRIC

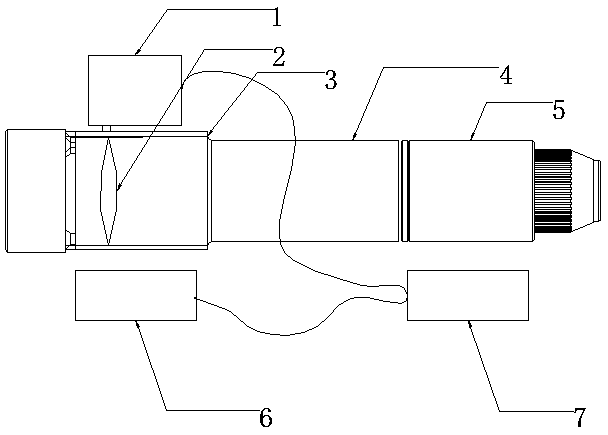

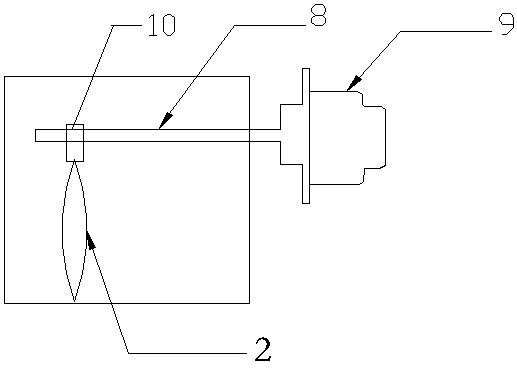

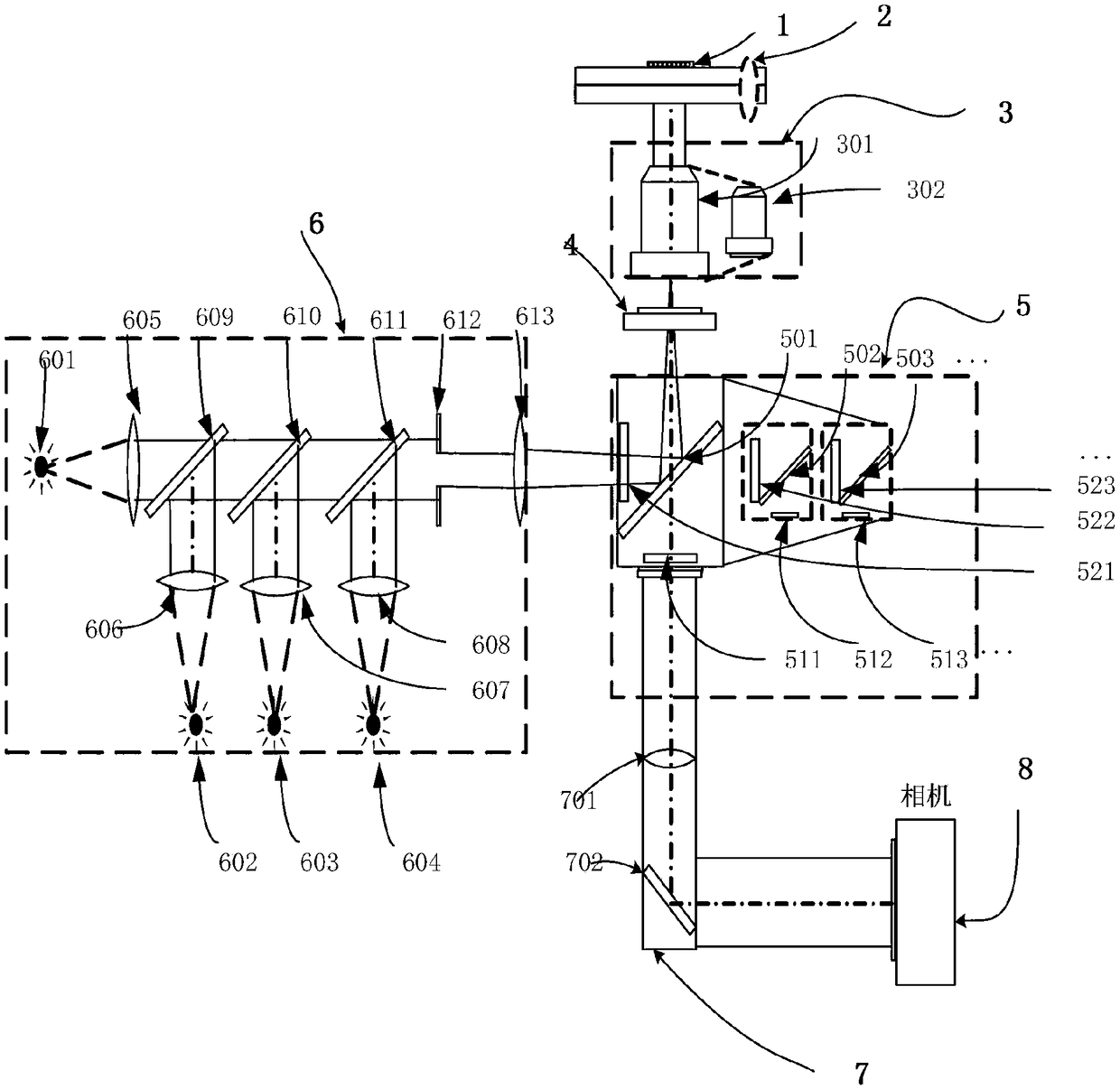

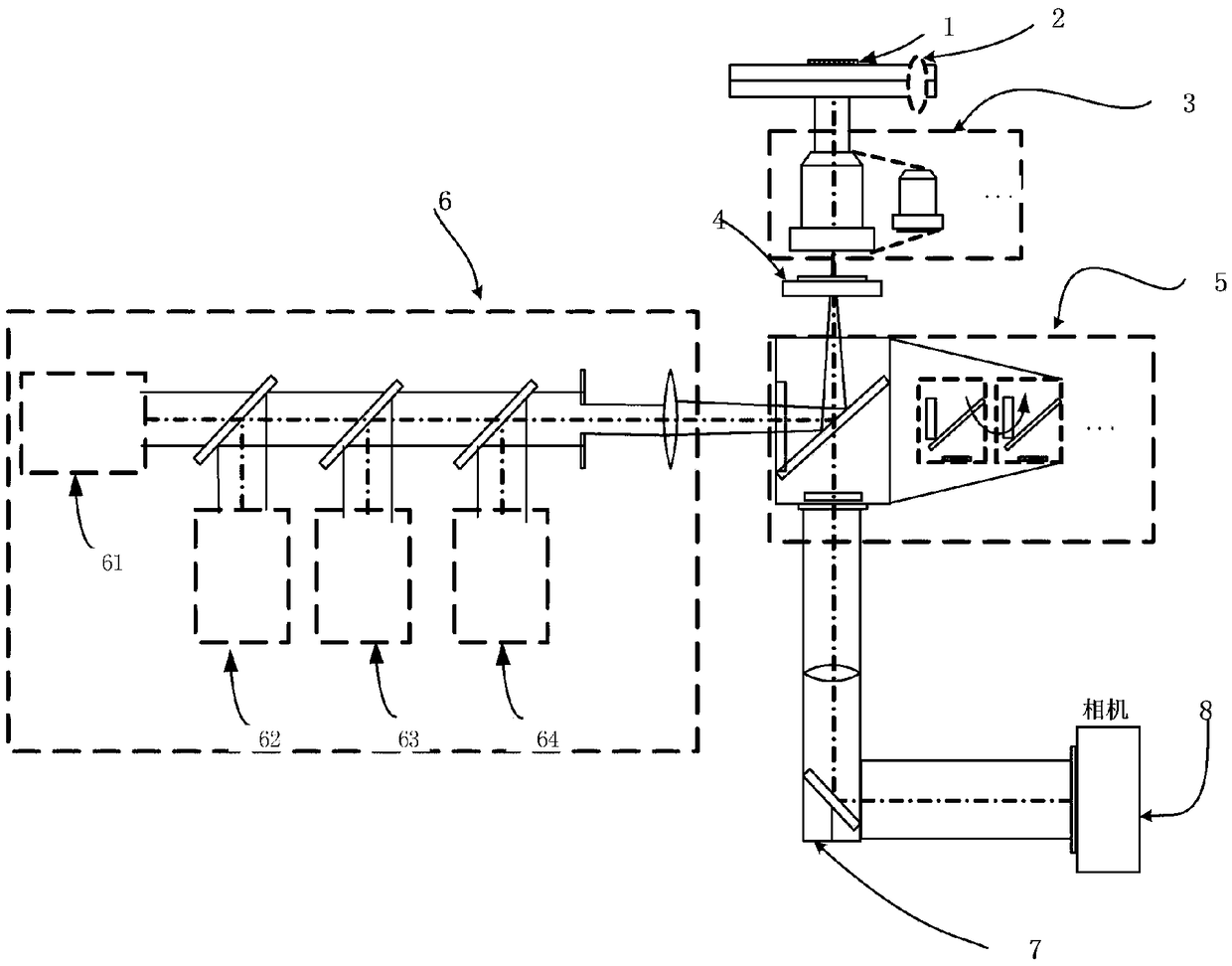

Real-time fluorescence detecting device of microreactor and operating method thereof

PendingCN109406479AHigh sensitivityHigh precisionFluorescence/phosphorescenceMicroreactorFluorescence

The invention discloses a real-time fluorescence detecting device of a microreactor and an operating method thereof. The real-time fluorescence detecting device of the microreactor comprises a biochip, a displacement platform, an objective lens component, an objective lens focusing device, an optical filter component, a light source device, an imaging light path component, a detector and a computer. The microreactor is placed in the biochip. The optical filter component is installed below the objective lens focusing device. The detector is connected with the optical filter component through the imaging light path component. The computer is electrically connected with the displacement platform, the objective lens focusing device and the detector. The light source device comprises exciting light sources, a field diaphragm and a first beam combining lens. There are multiple exciting light sources. The first beam combining lens is used for combining a light source of each exciting light source and forming a unified light path. The field diaphragm is installed in the unified light path after beam combining. The provided real-time fluorescence detecting device of the microreactor is capable of realizing multi-channel, high-sensitivity, large-area and rapid real-time detection to the microreactor.

Owner:SUZHOU HOTTOP INN INSTR TECH CO LTD CHINA +1

Iris diagnostic device

The invention relates to a diagnostic device and particularly discloses a diagnostic device for scanning the irises of eyes. The diagnostic device comprises a mainframe, a hand-held reader and a display; the diagnostic device is provided with a demountable lens, an above-1.3 megapixel CCD (charge-coupled device), an LED lamp and a storage module which can conveniently shoot sharp images; the shotimages can be saved as the computer general image formats, such as JPG, BMP and the like; and then, the results can be automatically analyzed by the computer image comparison technology, particularly, pits, gaps, color spots, lines, density and color variation can be judged from the iris images to obtain the diagnosis result reflecting the change in health conditions. The automatic iris diagnostic device has the advantages that the application is convenient, the collected iris images are sharp, the information is accurate and all-around, the structure is simple, the cost is low, the images can be saved and amplified, and the results can be easily analyzed and judged.

Owner:杨思蕴

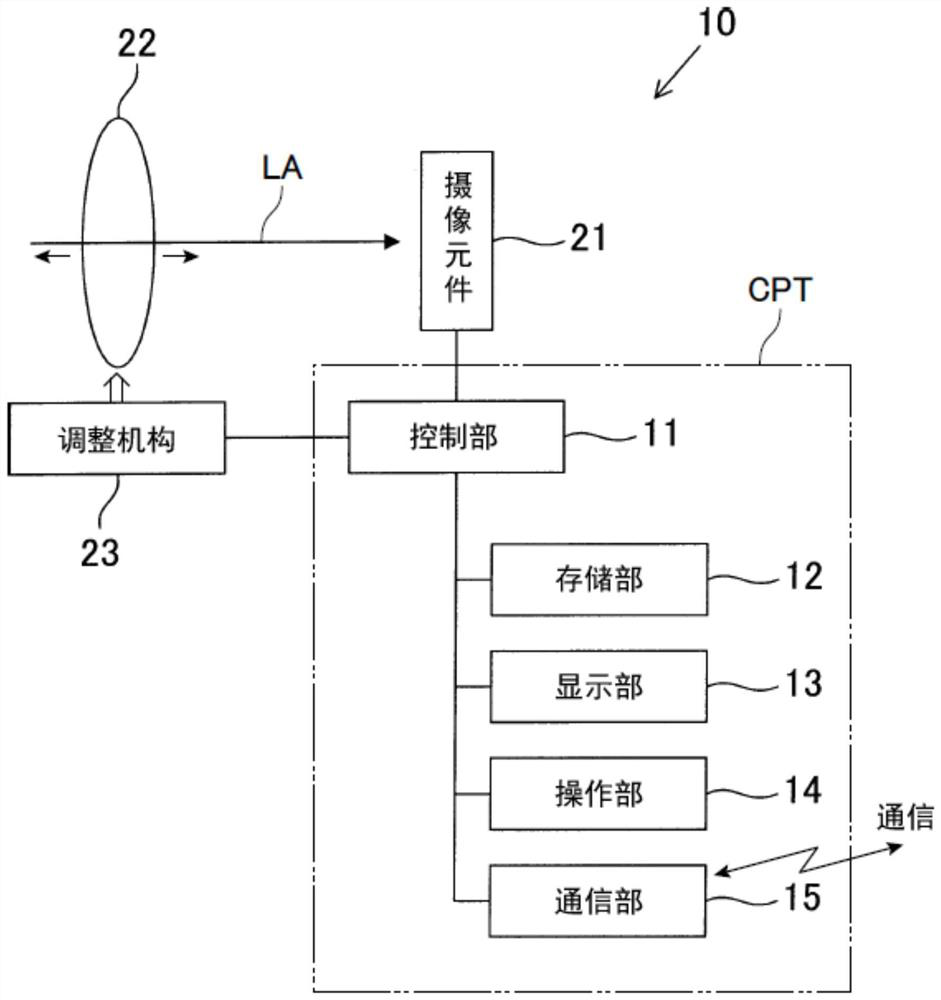

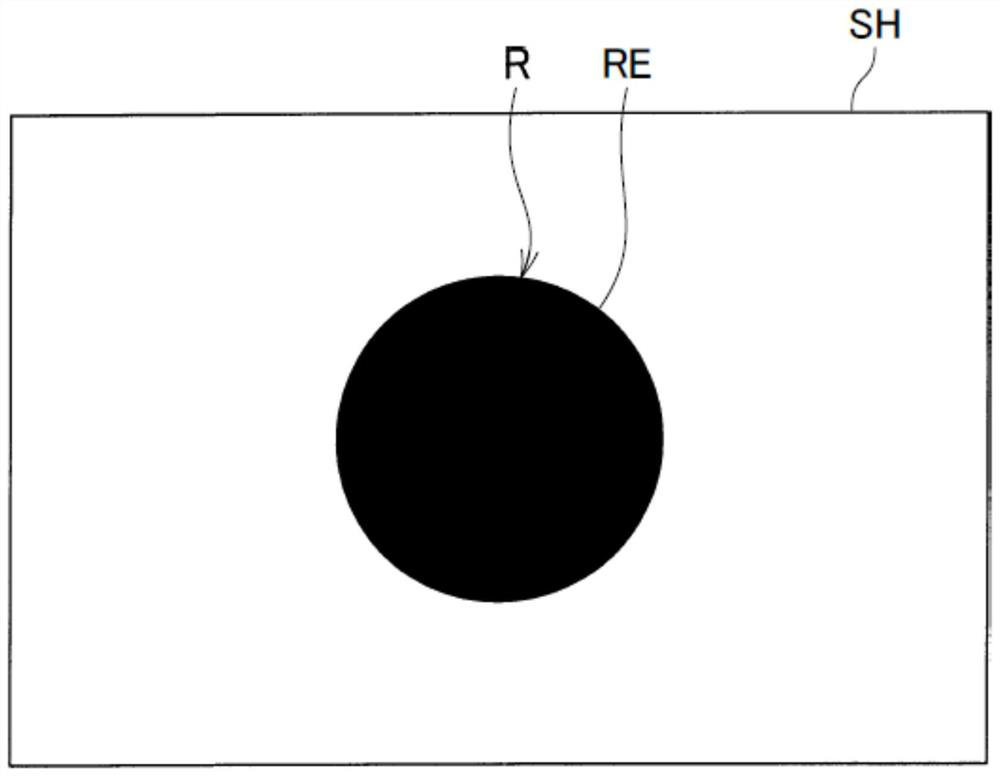

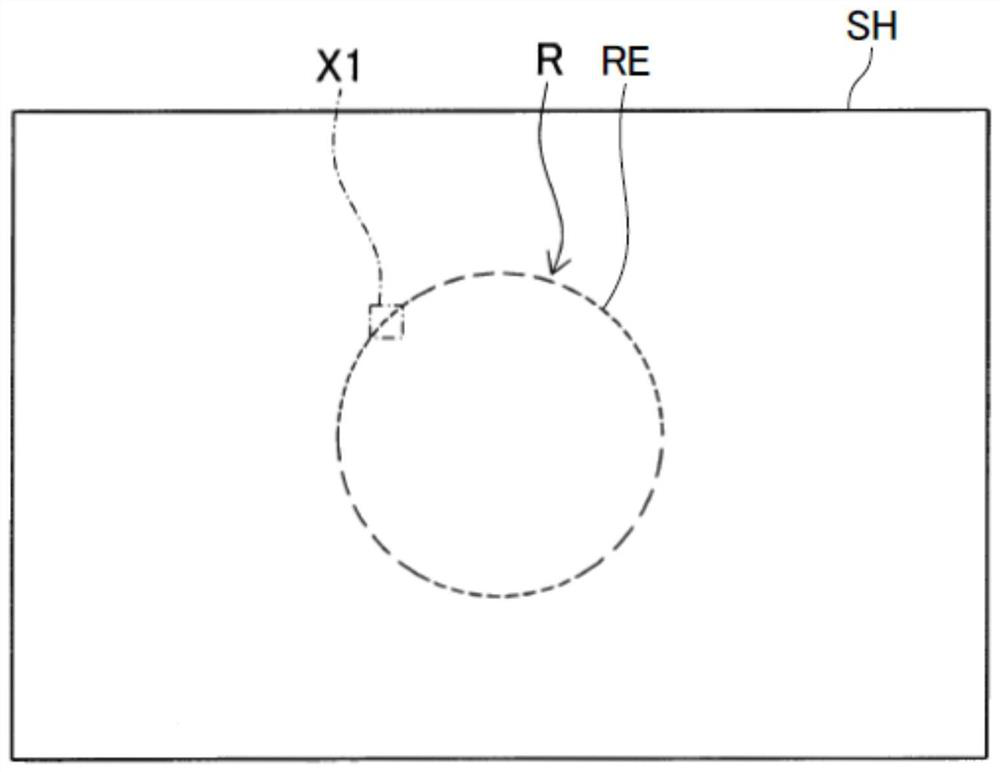

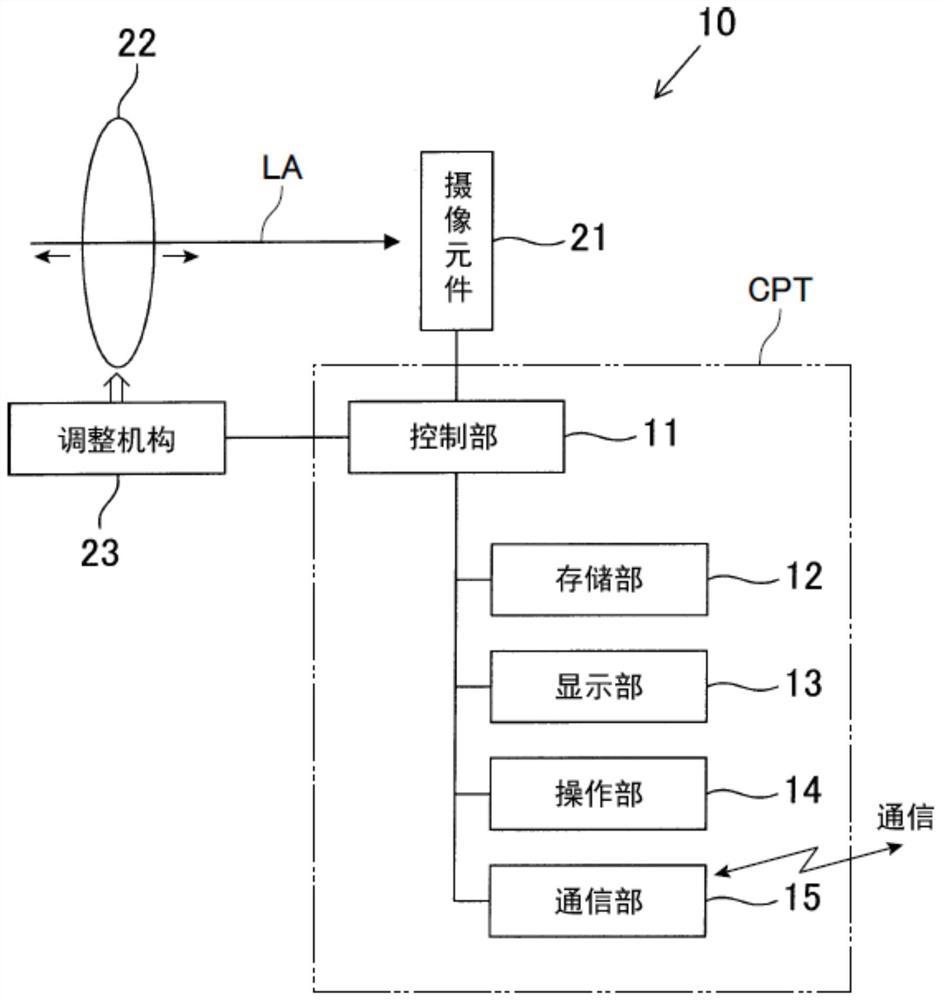

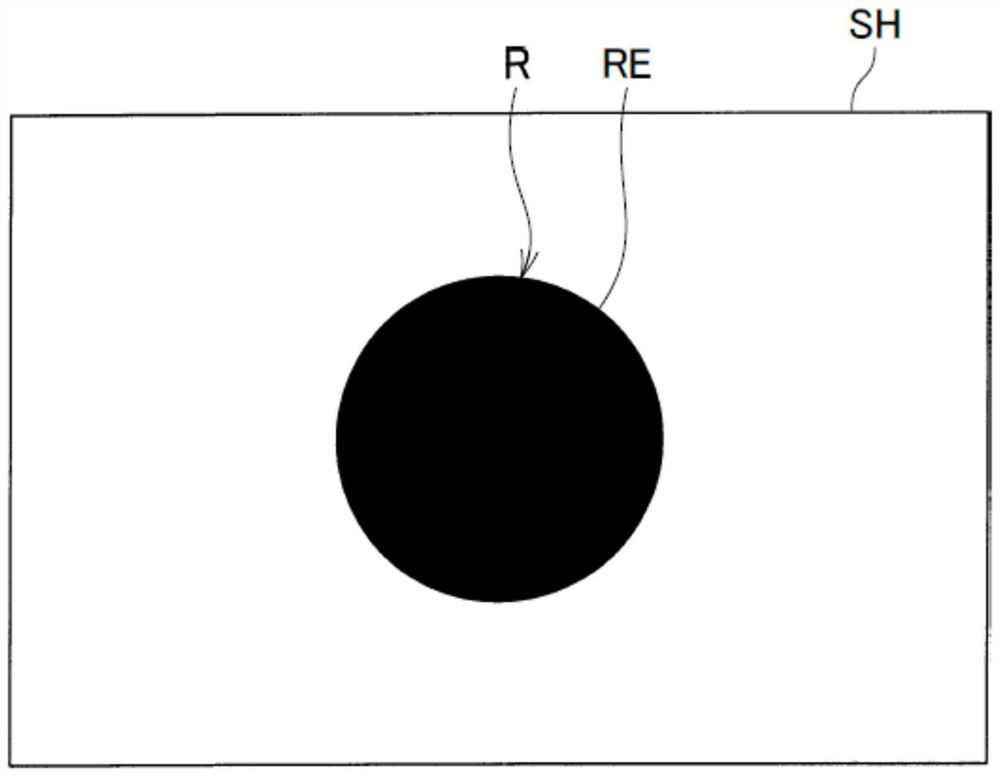

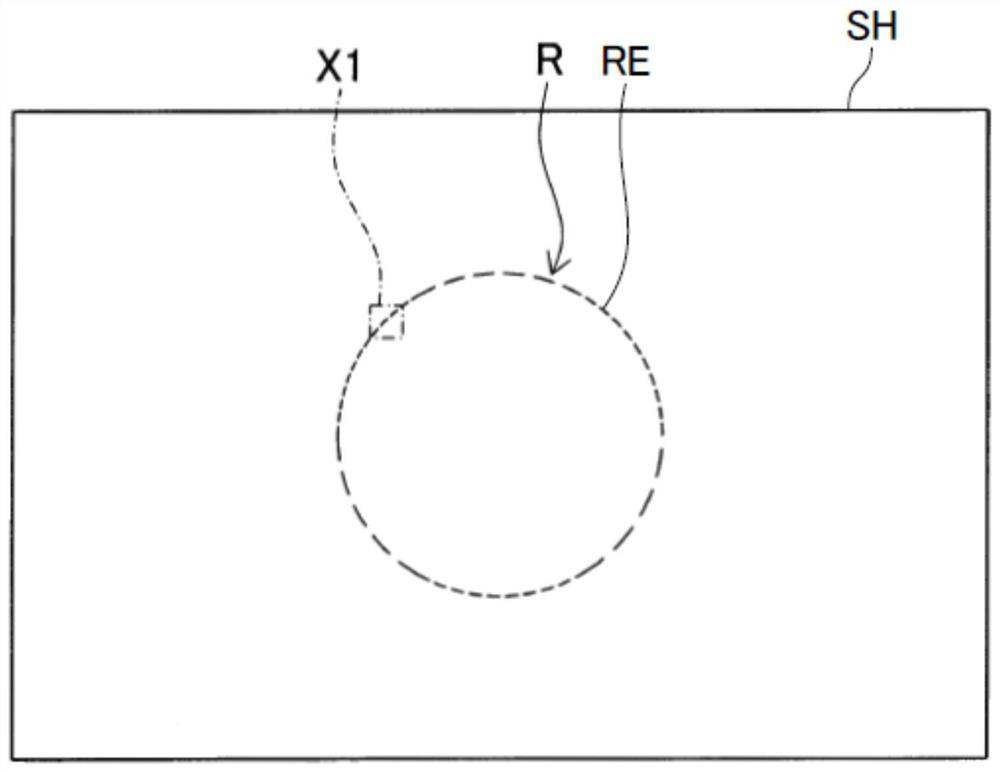

Imaging device provided with event-based camera

ActiveCN112689082AWith auto focus functionTelevision system detailsColor television detailsRadiologyAutofocus

An imaging device in which an autofocus function can be performed without using brightness information is provided. In an imaging device according to one aspect, a density of points obtained by plotting two-dimensional point data of a plurality of event data (PD) as points on a plane (SH), the event data outputted from an imaging element (21) in a predetermined period in a state in which a focal point of a light receiving lens (22) is adjusted by an adjustment mechanism (23), is calculated as a point density. When the point density is calculated, a control unit (11) drives and controls the adjustment mechanism (23) based on comparison results between the point density currently calculated and the point density last calculated to thereby adjust the focal point toward the in-focus position. In another aspect, an imaging device having an autofocus function can be provided without using event data output from the imaging element.

Owner:DENSO WAVE INC

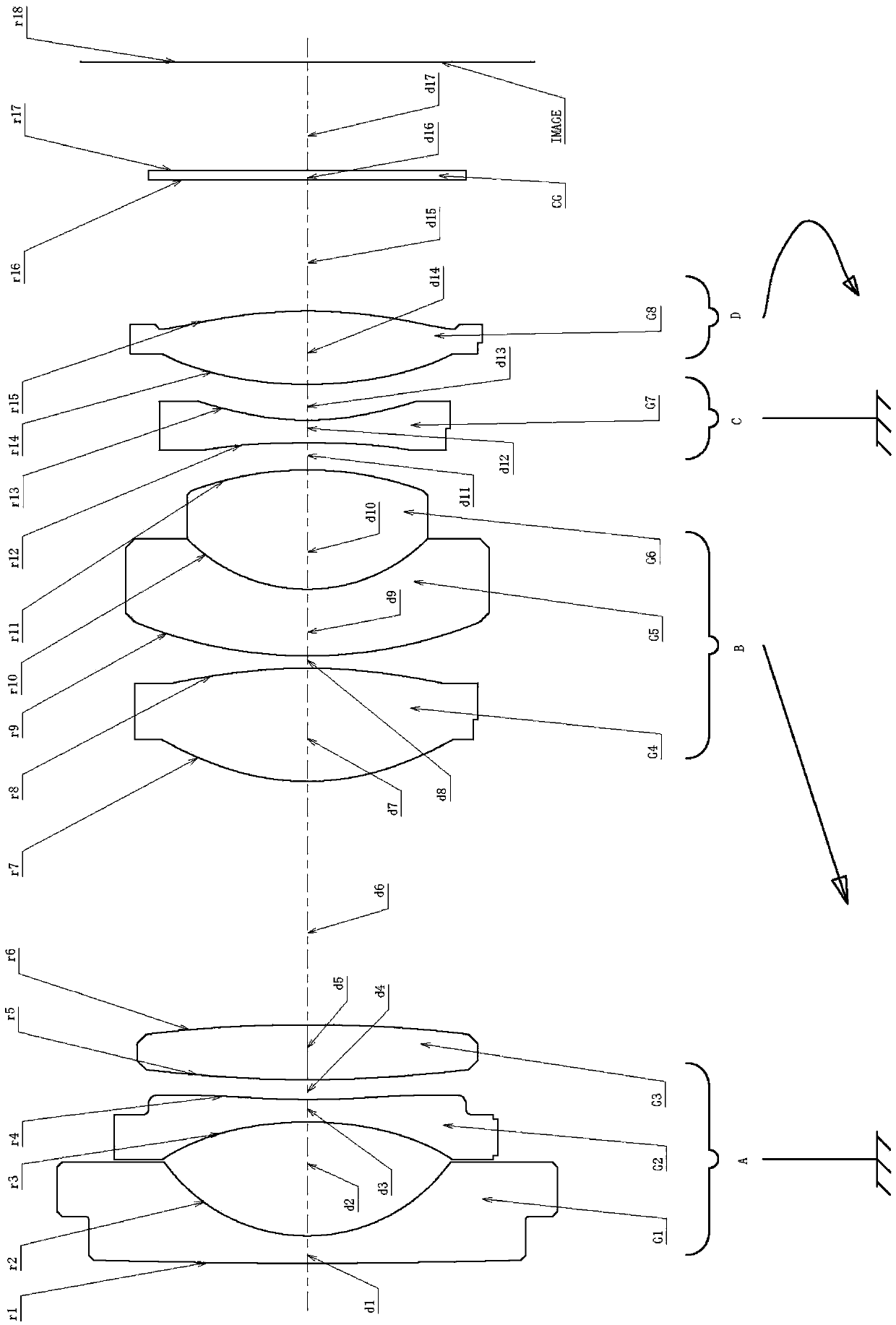

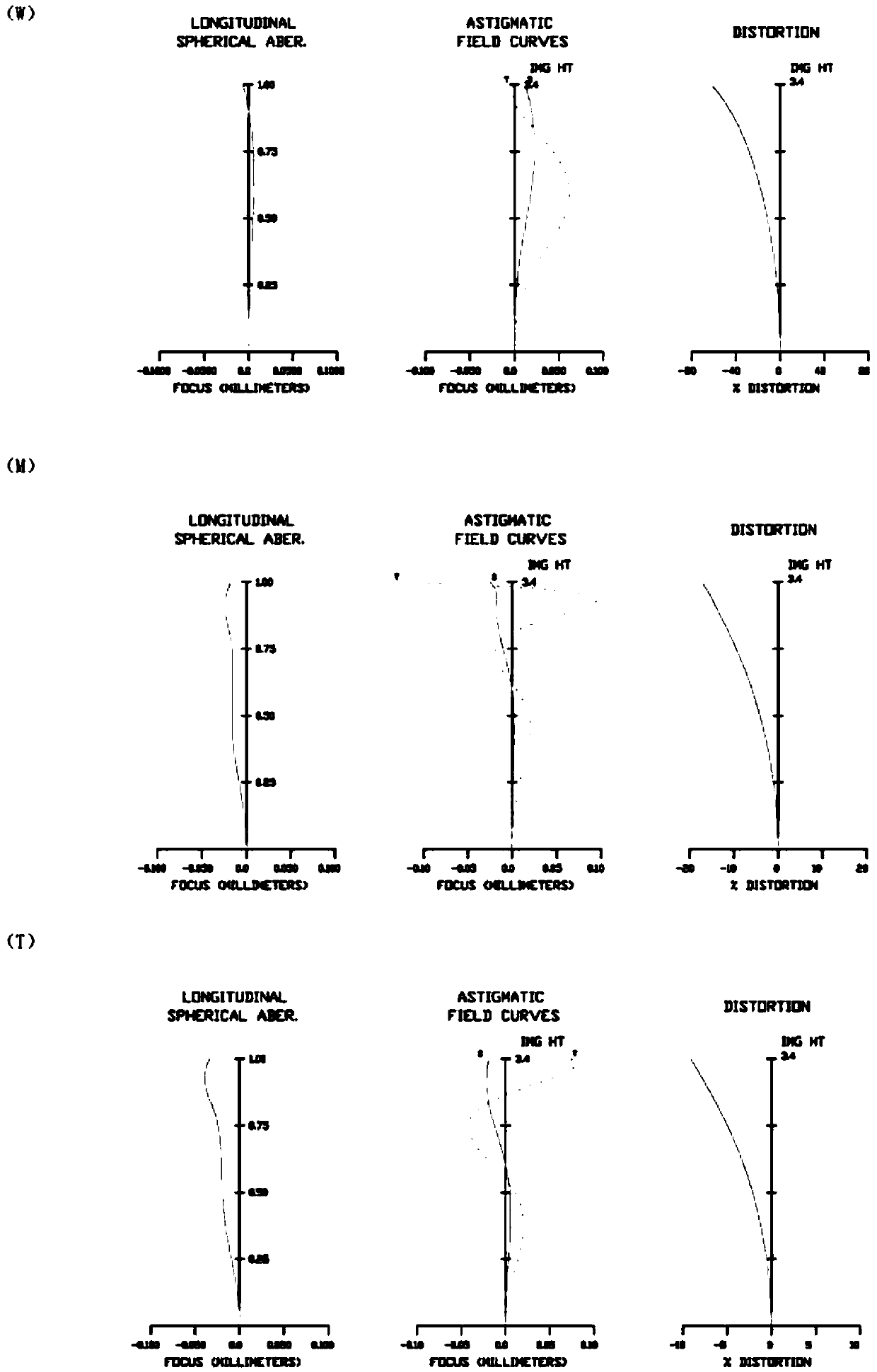

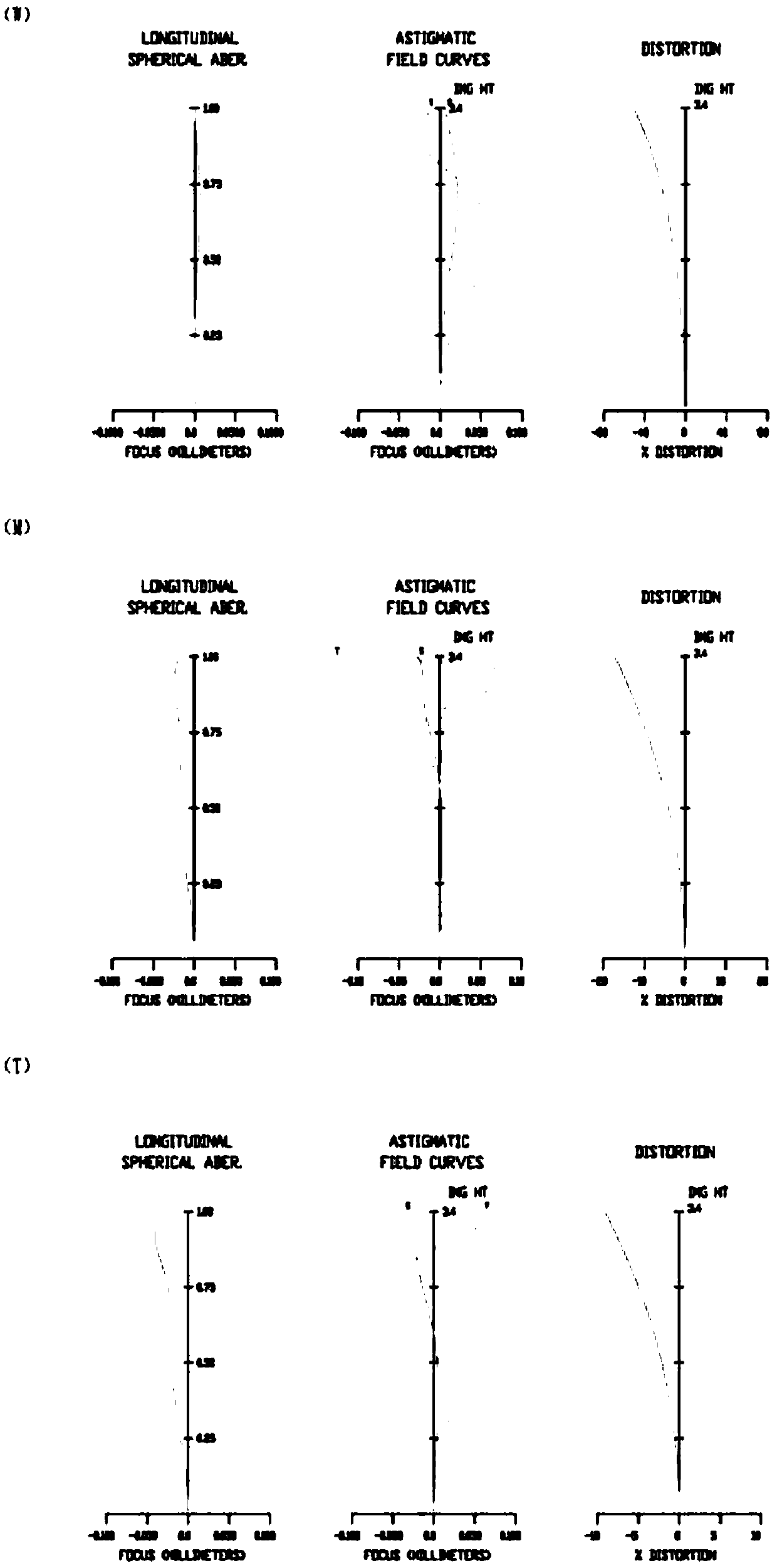

a zoom lens

ActiveCN106990515BIncrease chromatic aberrationChromatic aberration convergenceOptical elementsCamera lensOptical axis

A zoom lens is disclosed. An optical system consists, sequentially along a light incident direction, of a first lens group A having a negative focal power, a second lens group B having a positive focal power, a diaphragm S, a third lens group C having a negative focal power and a fourth lens group D with a positive focal power. The first lens group A and the third lens group C are always in a fixed state. The second lens group B is moved from an image side to an object side along the optical axis so that the lens field angle is zoomed from a wide-angle end to a telephoto end. At the same time, the fourth lens group D is moved correspondingly in a non-linear manner along the optical axis for correction and focusing with the image variation accompanying the zooming. The stability of the system image during the variation in the focal length is ensured.

Owner:JIAXING ZHONGRUN OPTICAL TECH

Camera module group

The invention relates to a camera module which comprises a circuit board, an image sensor and a lens module. The lens module comprises a first optical lens, a second optical lens, a third optical lens, a liquid lens and a micro-actuator actuator. The micro-actuator comprises a fixing part and a movement part which is provided with a through hole in which the first optical lens is embedded. The fixing part, the movement part and the image sensor are connected electrically. The second optical lens is connected to the third optical lens. The liquid lens embedded between the second optical lens and the third optical lens is connected to the image sensor. Rays are imagined on the image sensor through the first optical lens, the second optical lens and the third optical lens in turn. When the circuit board is electrified, an electrostatic force is generated due to an electric potential difference between the movement part and the fixing part so as to drive the movement part to move along the lens module optical axis for automatic focus.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Picture module

InactiveCN1203362CWith auto focus functionTelevision system detailsSolid-state devicesComputer moduleMiniaturization

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

An intrusion detection and alarm system based on multi-camera data fusion and its detection method

InactiveCN105894702BWith auto focus functionHigh degree of intelligenceClosed circuit television systemsBurglar alarmVideo monitoringVideocassette recorder

Owner:NANJING TECH UNIV +1

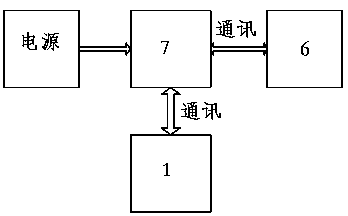

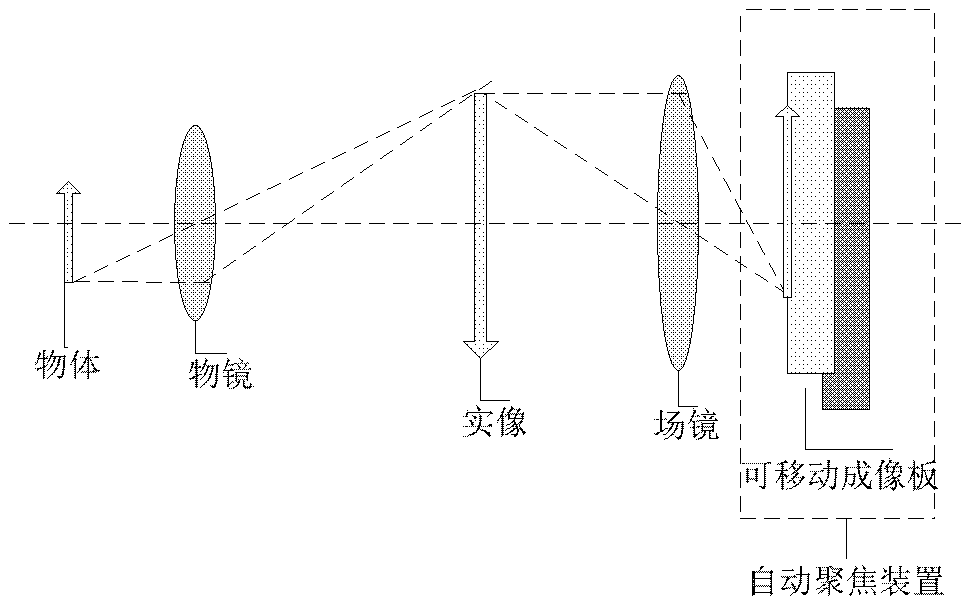

An automatic focusing device and system

ActiveCN105530429BRealistic autofocus functionImprove focus accuracyTelevision system detailsColor television detailsComputer hardwareEngineering

The invention relates to an automatic focusing device and system. Including Sensor drive unit, main control unit, and interface unit: the main control unit of the autofocus device executes the focus search algorithm to control the movement of the Sensor board, and it automatically focuses by adjusting the image distance. The present invention can realize automatic focusing without moving or changing the front-end optical system, improves focusing precision and efficiency, shortens focusing time, and reduces system complexity and cost.

Owner:TAGYE TECH HANGZHOU CO LTD

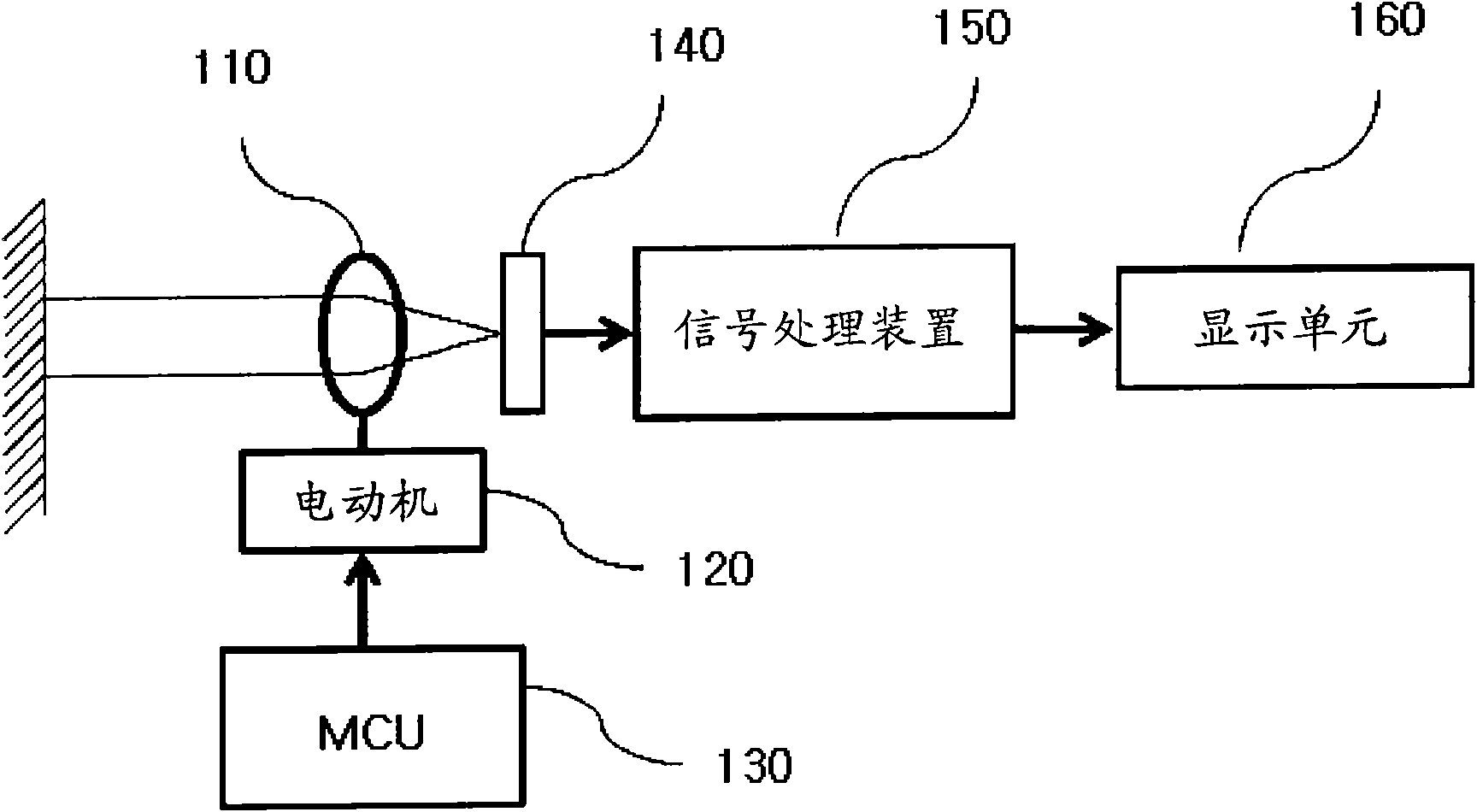

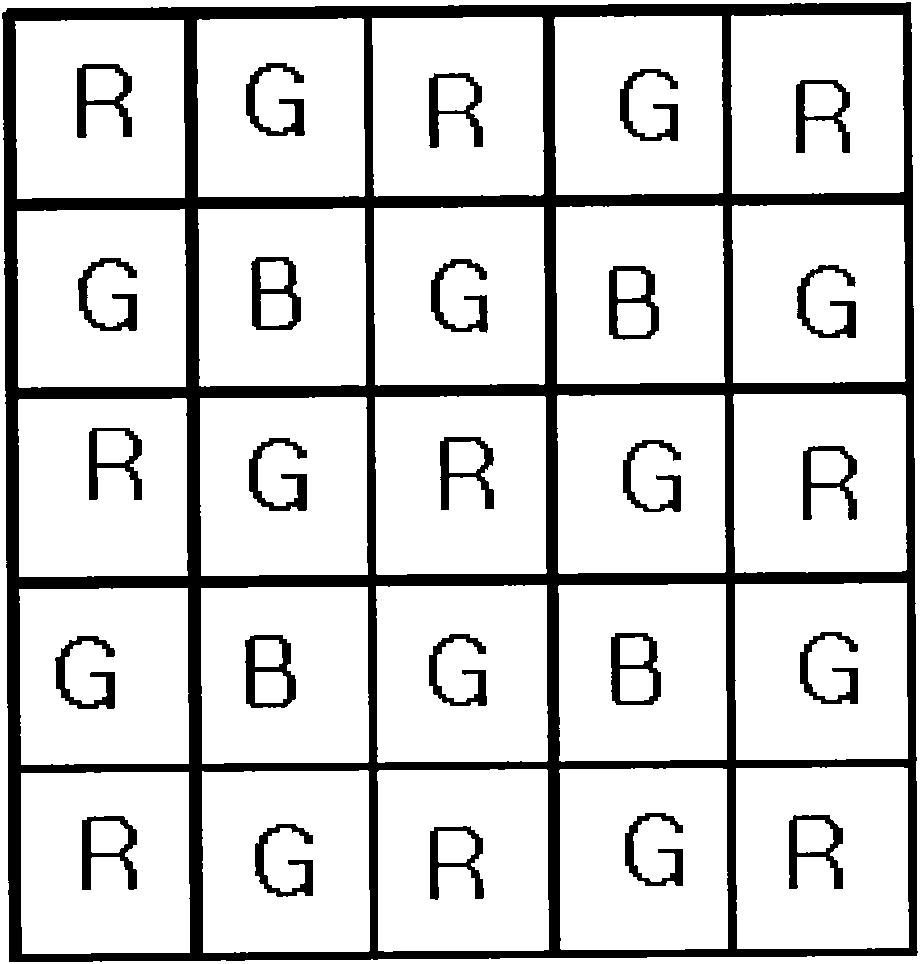

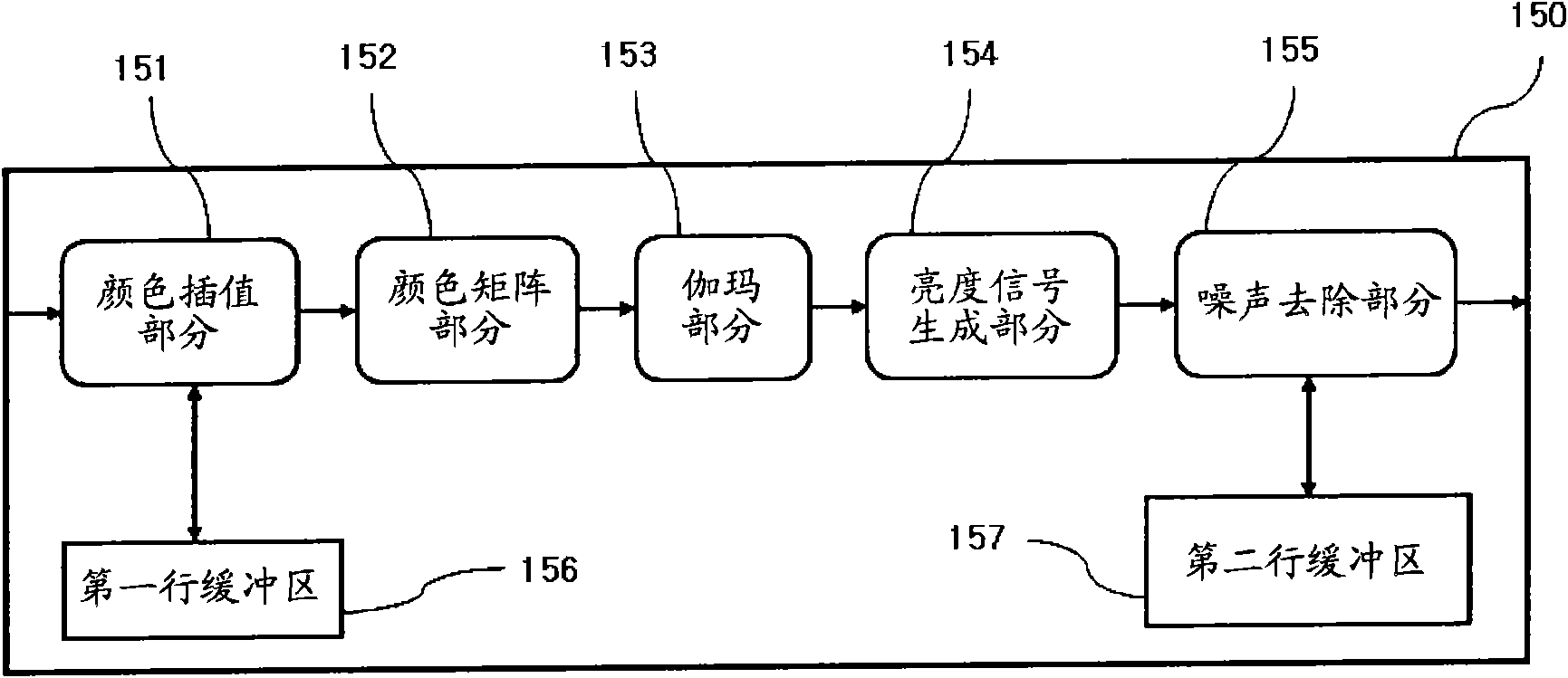

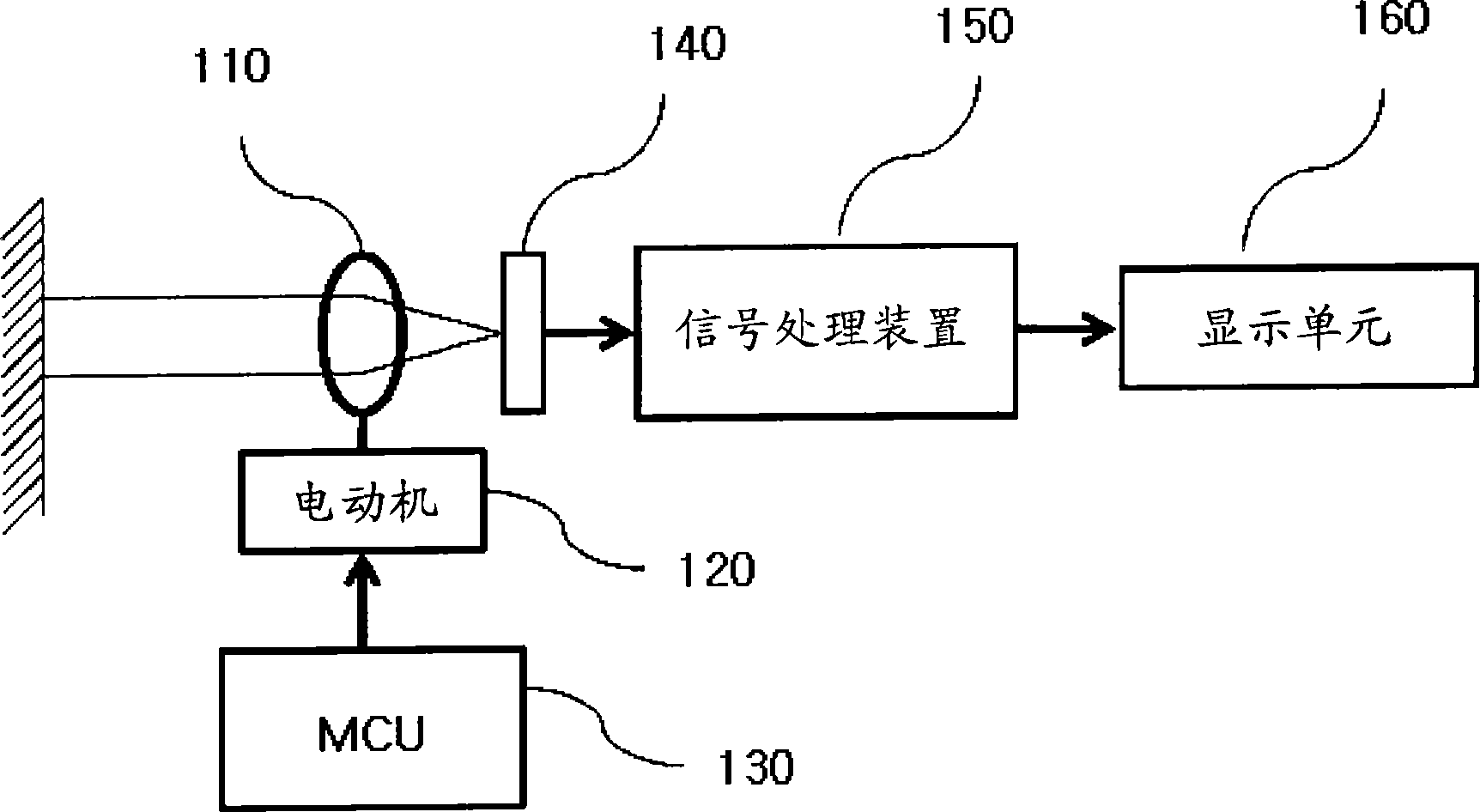

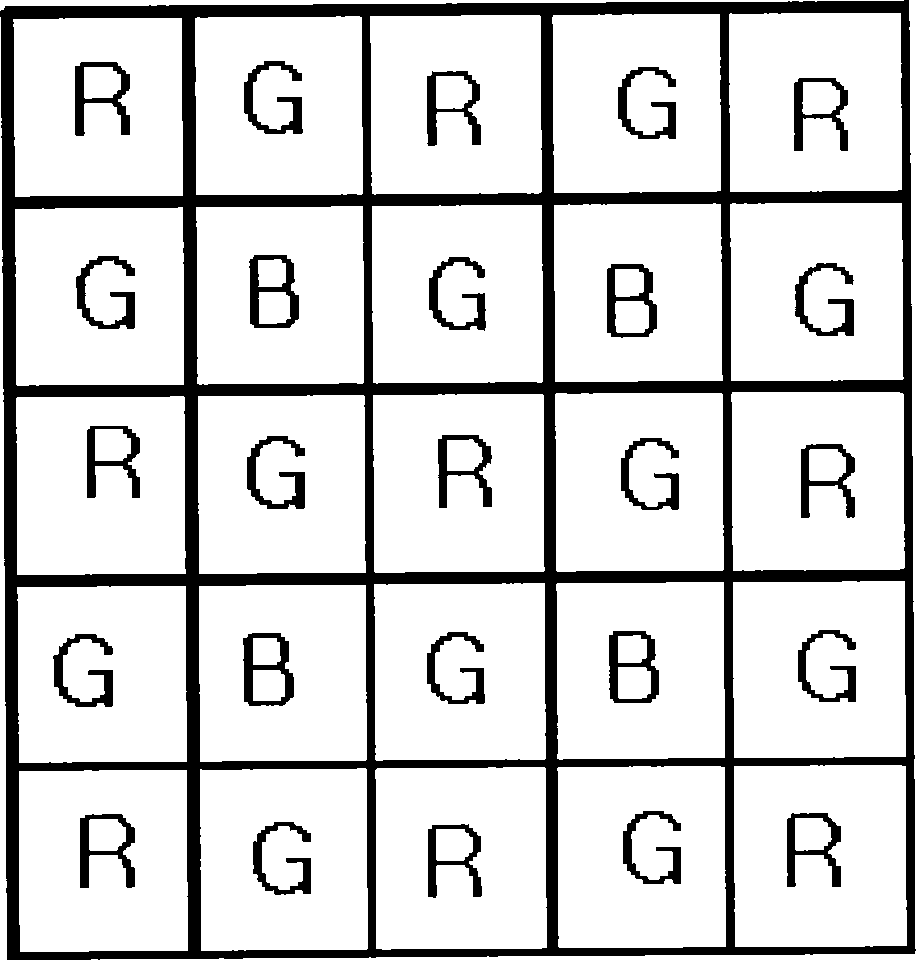

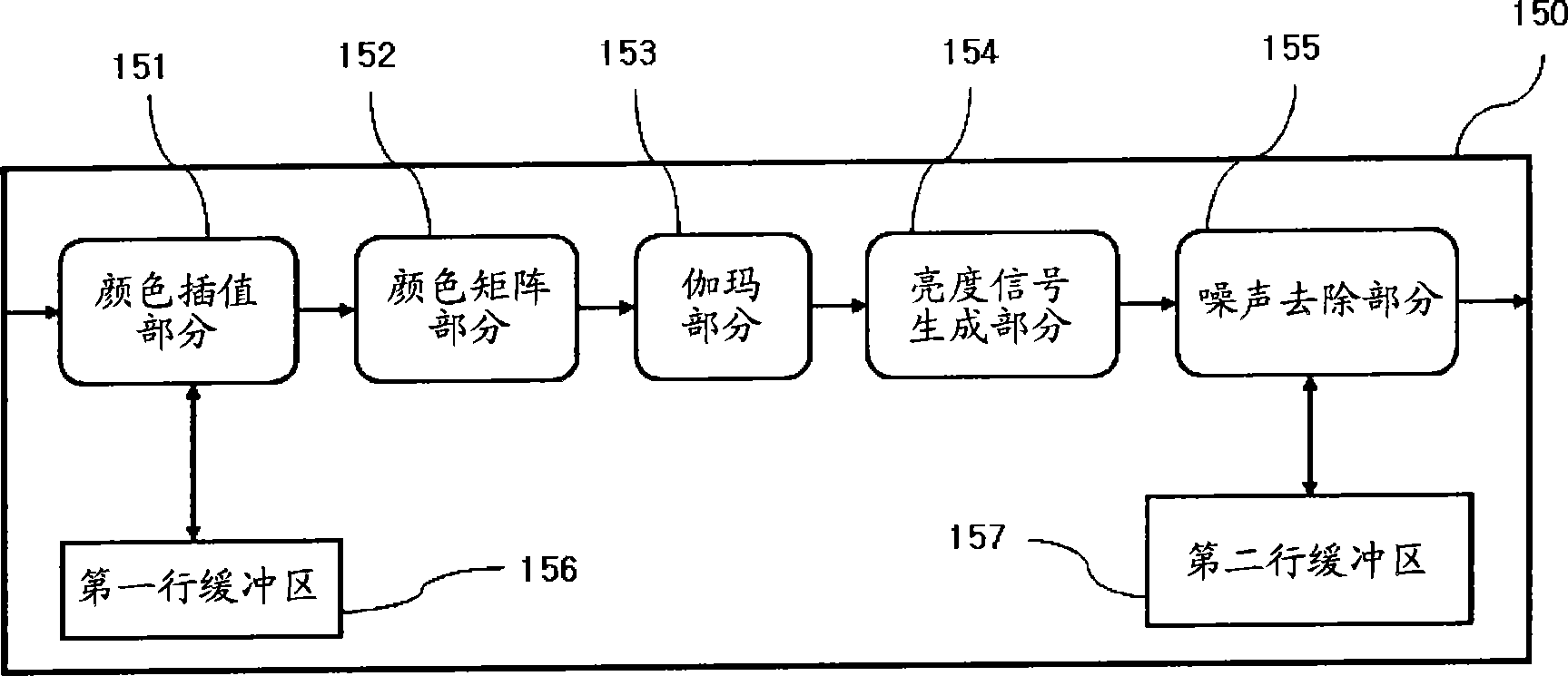

A fixed focus camera module built-in auto focusing function

ActiveCN102469252AWith auto focus functionTelevision system detailsGeometric image transformationComputer graphics (images)Camera module

The invention provides a fixed focus camera module having an auto focusing function. The fixed focus camera module having the auto focusing function includes a signal processing module capable of realizing the auto focusing function. Thus, even a single automatic focusing camera module is not used, the same effect with the real automatic focusing camera module can be obtained. The fixed focus camera module having the auto focusing function includes a lens module focusing light; an image sensor converting object image obtained through the image module into electric signals and outputting the electric signals; a signal processing module receiving and processing the electric signals output from the image sensor to output image signals and adjusting the focus of the lens module automatically; and a display module displaying the image signals output from the signal processing module.

Owner:SK HYNIX INC

Camera installation with event camera

ActiveCN112689082BWith auto focus functionTelevision system detailsColor television detailsComputer graphics (images)Radiology

The present invention provides a structure capable of realizing the auto-focus function without using brightness information. In the imaging device according to one aspect, in the state where the focus position of the light receiving lens (22) is adjusted by the adjustment mechanism (23), the point density corresponding to the number of points that will be transferred from the imaging element (21) within a certain period of time is calculated. ) is the density of points when the two-dimensional point data of the plurality of event data outputted as points is plotted on a predetermined plane. When the dot density is calculated, the control unit (11) controls the drive of the adjustment mechanism (23) according to the comparison result between the dot density and the last calculated dot density. As a result, the focus position is adjusted toward the focus position. In addition, as another aspect, it is possible to provide an imaging device having an autofocus function without using event data output from an imaging element.

Owner:DENSO WAVE INC

Projection device with automatic focusing function and automatic focusing method thereof

The invention relates to a projection device with an automatic focusing function and an automatic focusing method thereof. The steps are as follows: imaging an image which is projected on a screen by a first imaging lens by utilizing a second imaging lens on an image sensing unit; moving the second imaging lens, stating the image sensing unit to capture an image produced by the second imaging lens each time after the second imaging lens is moved, and calculating the definitions of the captured image; and comparing the definitions and obtain a largest value of all, and the position of the second imaging lens which corresponds to the largest value is a focusing position of the second imaging lens. Sequentially, moving the first imaging lens, each time after the first imaging lens is moved, capturing an image produced by the second imaging lens and calculating the definitions of the images; comparing the definitions of the images so as to obtain the largest value of all, and the positionof the first imaging lens which corresponds to the largest value is a focusing position of the first imaging lens.

Owner:ASIA OPTICAL CO INC

Camera module

InactiveCN100432733CReduce power consumptionWith auto focus functionTelevision system detailsColor television detailsOptical axisComputer module

A camera module has a lens section (10) including at least one lens (11), an imaging element (4) having a light receiving surface substantially perpendicular to the optical axis direction of the lens (11), a fixed section (30) provided on the outer periphery side of the lens section (10), a first elastic body (41a) provided on the opposite side of the imaging element (4) relative to the lens (11) and connecting the lens section (10) and the fixed section (30), and a second elastic body (41b) provided on the imaging element (4) side relative to the lens (11) and connecting the lens section (10) and the fixed section (30). The first elastic body (41a) and the second elastic body (41b) have the same shape, the first elastic body (41a) and the second elastic body (41b) are arranged so as to be opposed to each other with their center axes aligned, and the second elastic body (41b) is placed such that its shape is different from that shape of the first elastic body (41a) which is projected in the optical axis direction of the lens (11).

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

A fixed focus camera module built-in auto focusing function

ActiveCN102469252BWith auto focus functionTelevision system detailsGeometric image transformationAutofocusCamera module

The present invention provides a fixed-focus camera module with an auto-focus function, which includes a signal processing unit capable of implementing the auto-focus function, so that even without using a separate auto-focus camera module, it is possible to obtain a camera module similar to a true auto-focus camera module. same effect. The fixed-focus camera module with an auto-focus function includes: a lens unit that gathers light; an image sensor that converts an image of an object acquired through the lens unit into an electrical signal and outputs the electrical signal; a signal processing unit that receives and processing the electrical signal that has been output from the image sensor to output an image signal, and automatically adjusting the focus of the lens unit; and a display unit that displays the image signal output from the signal processing unit.

Owner:SK HYNIX INC

Logic circuit and extraction method for extracting image sharpness information with zero delay in pipeline mode

ActiveCN107911605BMeet autofocus needsAchieving autofocusTelevision system detailsColor television detailsImaging qualityGate array

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

A cell analysis chip and its cell fluorescence detection system and detection method

ActiveCN108956567BChange structural designStable structureFluorescence/phosphorescenceFluorescenceEngineering

The invention provides a cell analysis chip. A cell analysis chip, which includes a first reaction pool, a second reaction pool, a flow channel and a buffer pool, the first reaction pool and the second reaction pool communicate with one end of the flow channel through a conduit, and the buffer The pool is connected to the other end of the flow channel, and the flow channel is in a serpentine reciprocating shape, and there are several traps between the two adjacent reciprocating sections of the serpentine reciprocating flow channel. structure. The present invention also provides a fluorescence detection system and detection method with the above-mentioned cell analysis chip. The invention can greatly improve the detection efficiency, can meet the requirement of multi-color fluorescence detection, has a simple overall system design, and improves the detection sensitivity and working efficiency of the whole system.

Owner:GUANGDONG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com