Automatic focusing double-mirror cavity laser cutting head

A laser cutting head, automatic focusing technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of simple cutting head structure, uneven cooling of the lens, low efficiency, etc., to eliminate inaccuracy and Inconvenience, shorten the focus adjustment time, avoid the effect of cutting head damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

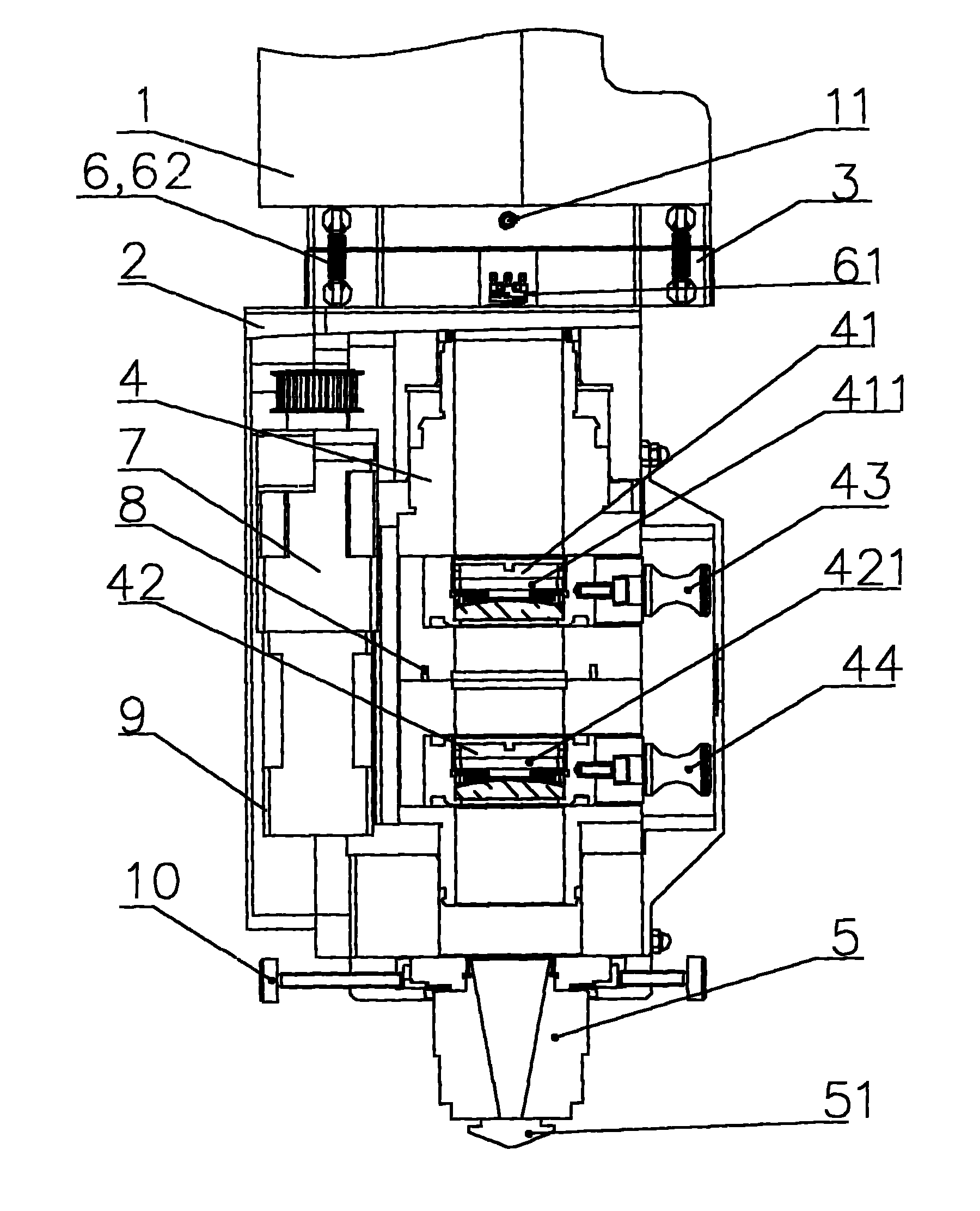

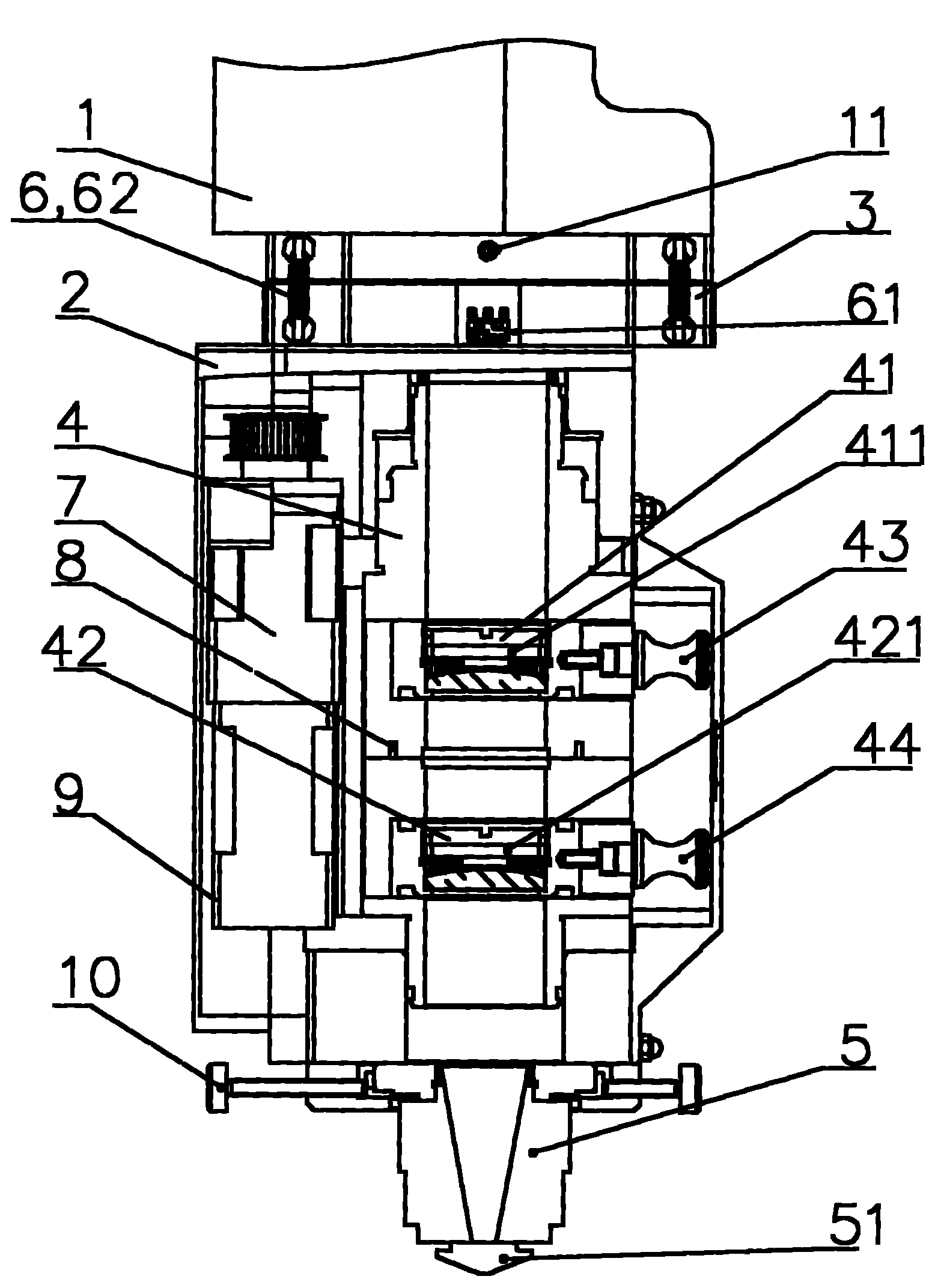

[0014] see figure 1 , the self-adjusting double-mirror cavity laser cutting head of the present invention is installed on the machine head 1 of the laser cutting machine, including a base 2 and a connecting head 3, a focusing lens assembly 4, a capacitor head 5, and a nozzle mounted on the base in sequence 51. Anti-collision mechanism 6, automatic focusing mechanism 7 and water cooling ring 8.

[0015] The focusing mirror assembly 4 among the present invention comprises the first mirror cavity 41 and the second mirror cavity 42 that are arranged on the laser light path in sequence, the first mirror cavity 41 is provided with the first drawer type mirror seat 411, and the second mirror cavity 42 There is a second drawer-type mirror holder 421 , a 7.5-inch focusing mirror is installed in the first drawer-type mirror holder 411 , and a 5-inch focusing mirror is installed in the second drawer-type mirror holder 421 . Next to the first mirror chamber 41, a first radial adjustment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com