A kind of preparation method of layered molybdenum sulfide nanosheet molecular separation membrane

A technology for molecular separation and molybdenum sulfide, applied in chemical instruments and methods, semi-permeable membrane separation, membrane technology, etc., can solve the problems of low flux, achieve good performance, simple film formation method, and easy large-scale preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

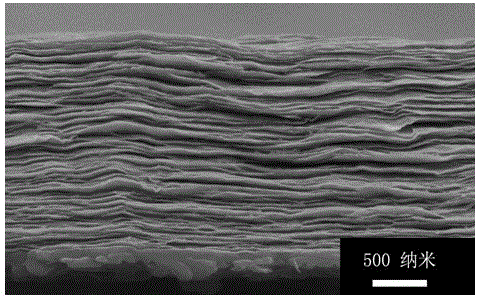

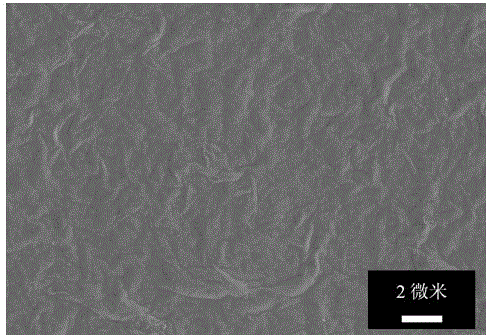

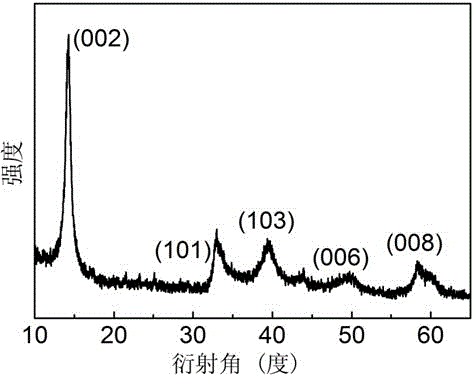

[0021] The steps of the preparation method of the layered molybdenum sulfide nanosheet molecular separation membrane are as follows:

[0022] 1) Under the condition of anaerobic water removal, 300-500 mg of molybdenum sulfide powder is added to 3-5 ml of 1.6 mM n-butyllithium n-hexane solution, the reaction vessel is sealed, and stirred at normal temperature for 24-48 hours to obtain The n-hexane suspension of molybdenum sulfide that has been intercalated, and the reaction solution is taken out from an oxygen-free and water-free environment;

[0023] 2) filter the reaction solution, wash the filter cake with 300-500 ml of n-hexane to obtain a semi-dry powder;

[0024] 3) Add 100 ml of water to the semi-dry powder, stir for 3-5 minutes, and ultrasonically disperse for 1 hour to obtain a suspension;

[0025] 4) Centrifuge the suspension and centrifuge at 8000-9000rpm for 10-30 minutes to remove large particles that have not been peeled off and excess lithium hydroxide;

[0026...

Embodiment 1

[0030] 1) Add 300 mg of molybdenum sulfide powder to 3 ml of 1.6 mM n-butyllithium n-hexane solution under the condition of anaerobic water removal, seal the reaction vessel, and stir at room temperature for 24 hours to obtain intercalated sulfide The n-hexane suspension of molybdenum, the reaction solution is taken out from the anaerobic and anhydrous environment;

[0031] 2) filter the reaction solution, wash the filter cake with 300 milliliters of n-hexane to obtain a semi-dry powder;

[0032] 3) Add 100 ml of water to the semi-dry powder, stir for 3 minutes, and ultrasonically disperse for 1 hour to obtain a suspension;

[0033] 4) The suspension is centrifuged and centrifuged at 8000rpm for 10 minutes to remove large particles that have not been peeled off and excess lithium hydroxide;

[0034] 5) Collect the supernatant, put it into a 35,000 Da dialysis bag, wash off excess impurities with deionized water, replace the deionized water every 4 hours on the first day, and ...

Embodiment 2

[0037] 1) Add 500 mg of molybdenum sulfide powder to 5 ml of 1.6 mM n-butyllithium n-hexane solution under the condition of anaerobic water removal, seal the reaction vessel, and stir at room temperature for 48 hours to obtain intercalated sulfide The n-hexane suspension of molybdenum, the reaction solution is taken out from the anaerobic and anhydrous environment;

[0038] 2) filter the reaction solution, wash the filter cake with 500 milliliters of n-hexane to obtain a semi-dry powder;

[0039] 3) Add 100 ml of water to the semi-dry powder, stir for 3-5 minutes, and ultrasonically disperse for 1 hour to obtain a suspension;

[0040] 4) The suspension was centrifuged and centrifuged at 9000 rpm for 30 minutes to remove large particles that could not be peeled off and excess lithium hydroxide;

[0041] 5) Collect the supernatant, put it into a 35,000 Da dialysis bag, wash away excess impurities with deionized water, change the deionized water every 6 hours on the first day, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com