Pelletizer

A granulator and granulation technology, which is applied in the direction of raw material extrusion granulation, etc., can solve the problems of deterioration of stress conditions, shortening of bearing life, and reduction of cutting efficiency, etc., to achieve flexible and convenient use, long service life, and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

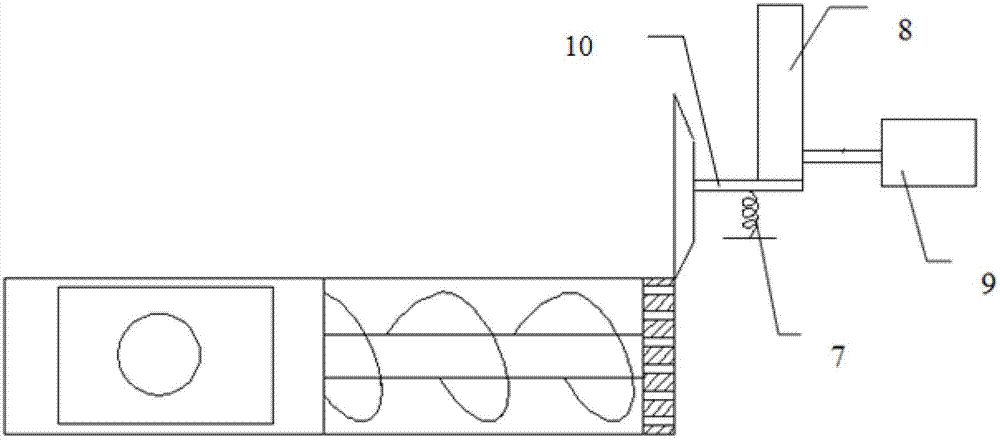

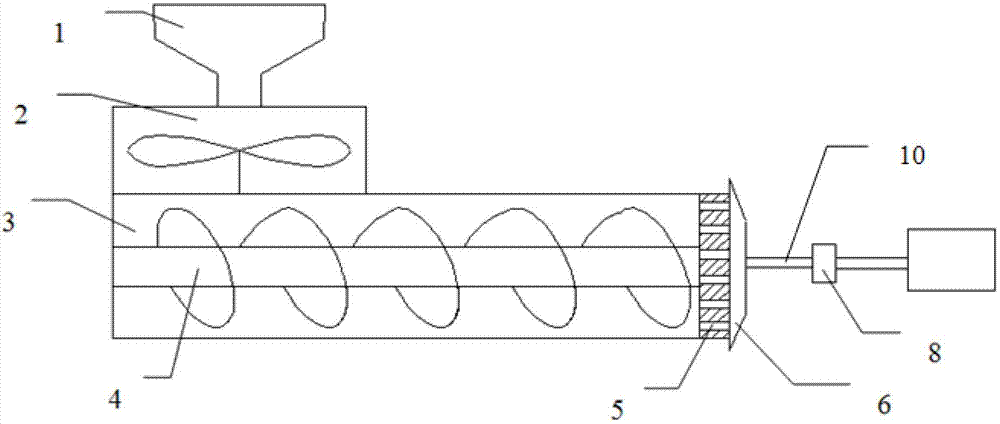

[0017] like figure 1 , figure 2 As shown, the present invention provides a granulator, comprising a feeding cylinder 1 connected in sequence, a stirring device, an extruding device and a pelletizing device, and the pelletizing device includes a pelletizing knife 6, a driving motor 9, and a drive rod 10, the return spring 7 and the eccentric wheel 8, the granulator 6 is connected to the transmission rod 10, one end of the return spring 7 is fixed and the other end is connected to the transmission rod 10, and the eccentric wheel 8 is connected to the drive rod 10. The motor 9 is connected, and the eccentric wheel 8 is in line contact with the transmission rod 10 .

[0018] The pelletizing knife 6 is polygonal, and each side of the pelletizing knife has a blade, preferably the number of sides of the pelletizing knife is 3 or 4. Setting the granulation knife as a polygonal blade can increase the service life of a granulation knife. Only one of the granulation knife edges is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com