Centrifugal separation device

A centrifugal separation and centrifugal device technology, applied in centrifuges, centrifuges with rotating drums, etc., can solve the problem that high-density materials are difficult to continuously and smoothly discharge the separation cavity, reduce work efficiency and separation accuracy, and improve sorting The lower limit of particle size and other problems can achieve the effect of remarkable separation effect, easy control of separation ratio, and avoidance of wall accumulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

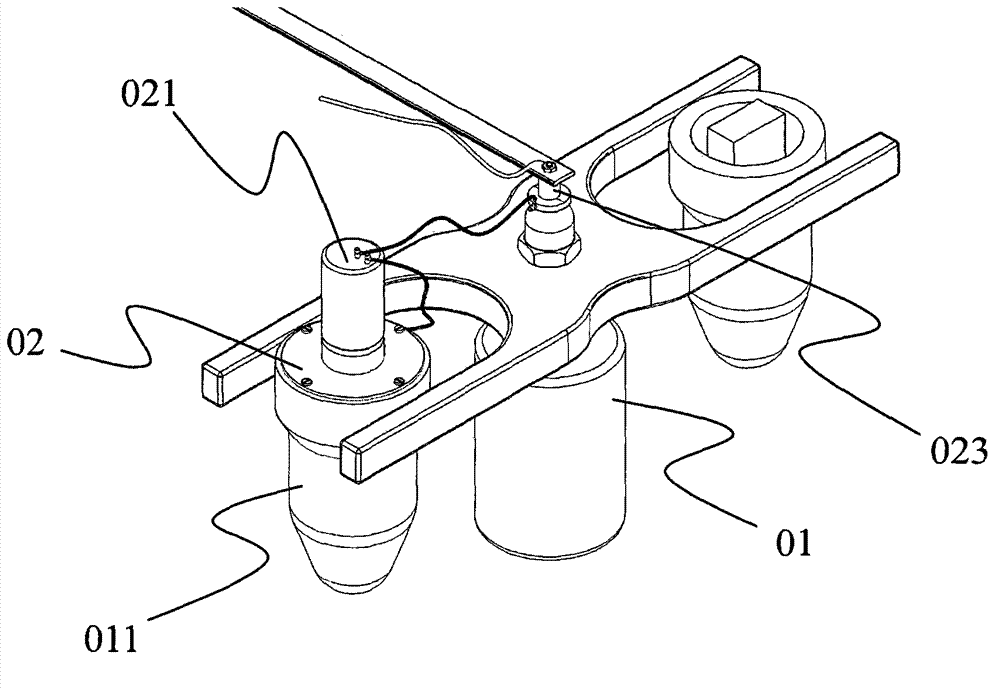

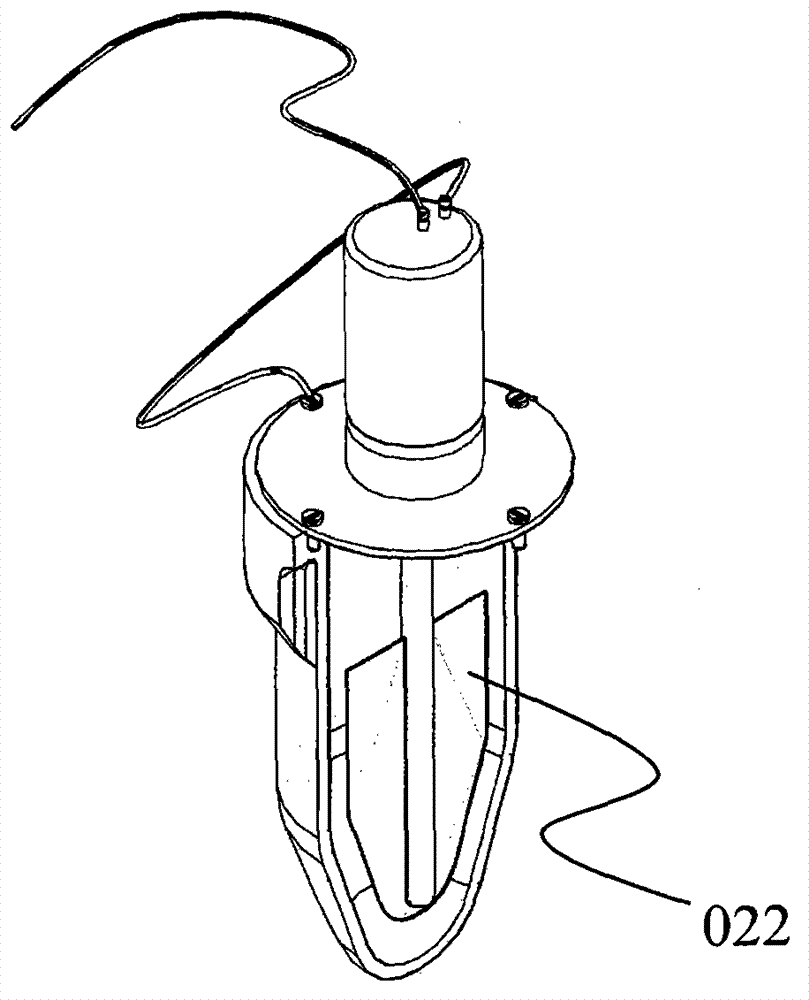

[0042] Example 1 , Small centrifugal separation device for intermittent operation.

[0043] The specific technical solution is to install a rotating excitation device 02 in the centrifuge cup 011 of the existing swinging rotor centrifuge 01, which can rotate and stir the materials in the cup during the centrifugation process. The rotary excitation device can be fixed on the mouth of the centrifuge cup with a flat stirring blade 022 driven by a DC motor 021, and a slip ring carbon brush 023 is arranged on the central axis of the centrifuge, and one phase of the two-phase power line of the DC motor It is directly connected to the centrifuge, the other phase is connected to the voltage regulating DC power supply through the slip ring carbon brush, and the other phase of the DC power supply is connected to the centrifuge. There is a large gap between the edge of the flat stirring blade and the wall of the centrifugal cup.

[0044] When working, put the slurry material in the ce...

Embodiment 2

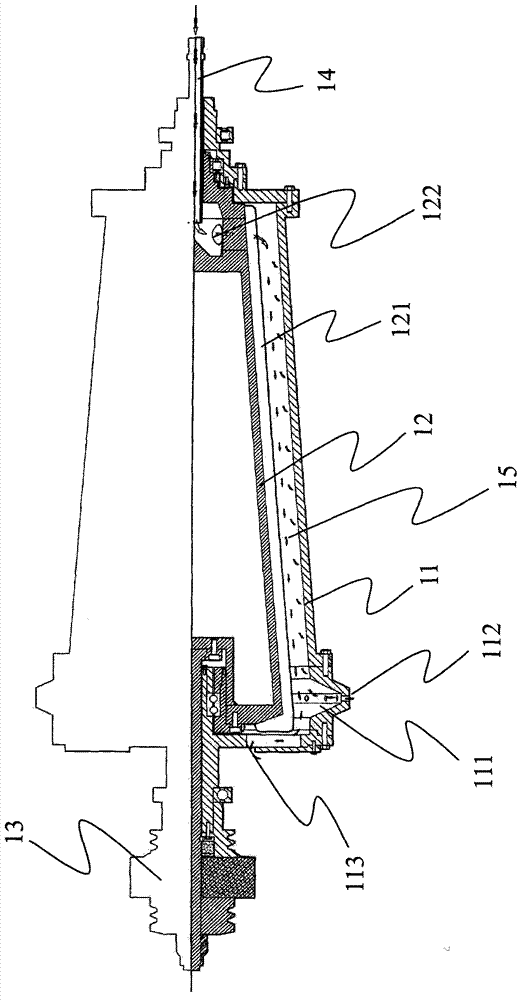

[0045] Example 2 , Straight blade centrifugal separation device.

[0046] Concrete scheme, its centrifugal device comprises outer drum 11, inner drum 12, differential transmission device 13, feed pipe 14, and outer drum is the hollow round drum of conical frustum shape, and the side is provided with the weight of band chute 111 respectively near lower bottom surface and lower bottom surface. The material outlet 112 and the light material outlet 113, the inner drum as the mechanical excitation device is a round platform similar in shape to the outer drum, and several straight blades 121 are arranged on the side. The end with the smaller diameter of the outer drum and the inner drum is called the top end, and the end with the larger diameter is the bottom end. The differential transmission device has the same structure as the corresponding part of the existing decanter centrifuge, and its function is to drive the outer drum and the discharge screw to rotate at a differential s...

Embodiment 3

[0048] Example 3 , Double helical blade centrifugal separation device.

[0049] The device includes an outer drum 21 , an inner drum 22 , an excitation screw 221 , a heavy material discharge screw 222 and a differential transmission device 23 . The outer drum is a centrifugal device, which consists of a straight cylinder and a cone whose bottom surface matches the straight cylinder to form a cavity. The inner drum and the excitation screw are mechanical excitation devices. The inner drum and the outer drum are similar in shape, and the inner drum and the outer drum jointly form a separation chamber 24 . The straight part and the conical part of the inner drum and the outer drum are respectively called the straight section and the cone section, the junction of the straight section and the cone section of the inner drum and the outer drum is called the shoulder, and the other end of the straight section is called the bottom. A feed inlet 223 is arranged in the middle of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com