Engine cylinder block cast casting method

A technology for engine cylinder blocks and castings, applied in the field of castings, can solve problems such as poor tensile strength and hardness uniformity, achieve the effects of reducing wall thickness sensitivity, reducing microstructure differences, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] In the smelting furnace, the metal charge is melted into molten iron. When the temperature of the molten iron reaches 1520-1550°C, it is poured into the ladle from the smelting furnace. Within a fourth period of time, the A inoculant with a weight of 0.3% of the total weight of the molten iron and a particle size of 0.2-0.6 mm is evenly and dispersedly sprinkled on the liquid flow through a quantitative funnel, and the molten iron is inoculated for the first time in the ladle; When the temperature of the molten iron is 1400-1420°C, inject the molten iron from the ladle into the casting cavity, from the injection amount of the molten iron being one quarter of the total weight of the molten iron to the four fifths of the total weight of the molten iron Within a certain period of time, the B inoculant with a weight of 0.07% to 0.13% of the total weight of the molten iron and a particle size of 0.4 to 0.8mm is evenly and dispersedly sprinkled on the liquid flow through a qua...

Embodiment 2

[0027] The only difference from Example 1 is that the time for adding the inoculant is not limited in the first inoculation treatment and the second inoculation treatment.

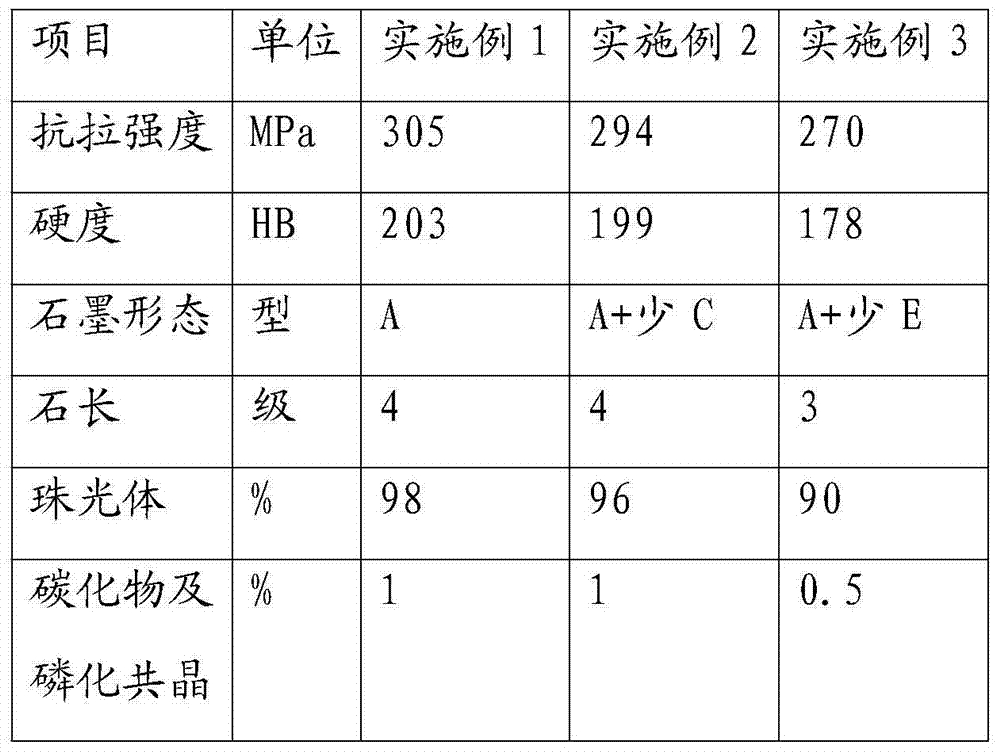

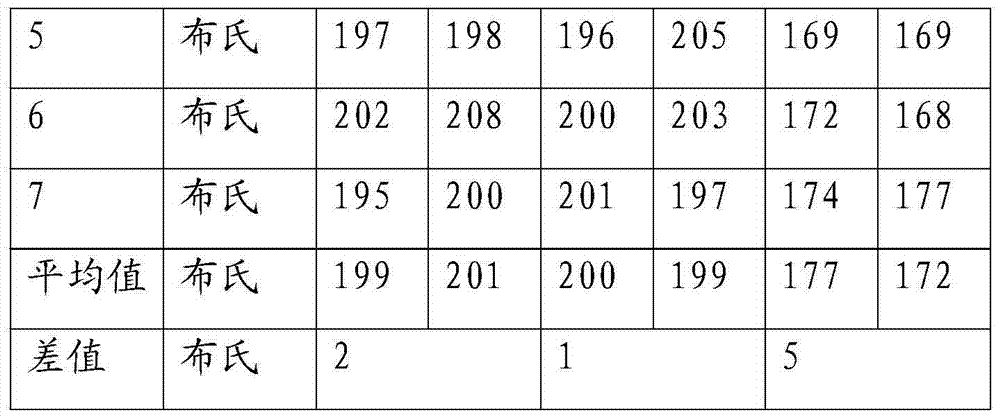

[0028] The results of testing the castings produced according to the process of Example 2 are shown in Table 1-1 and 2-2.

Embodiment 3

[0030] The difference from the embodiment is only that: the one-time inoculation process in the background technology is adopted, that is, the metal charge is melted into molten iron in the smelting furnace, and when the temperature of the molten iron reaches 1520-1550 ° C, it is poured into the ladle from the smelting furnace, and the A inoculant with a weight of 0.3% of the total weight of the hot metal from the furnace and a particle size of 0.2-0.6 mm or an inoculant with a weight of 0.07% to 0.13% of the total weight of the molten iron and a particle size of 0.4-0.8 mm is placed in the ladle in advance. At the bottom, when the molten iron is poured into the ladle, an inoculation treatment is carried out in the ladle, and after inoculation treatment, it is poured into the cavity of the casting and cast into shape. Wherein, all parameters of A inoculant or B inoculant are consistent with those in Example 1.

[0031] The casting results produced according to the process of E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com