Casting shell drilling jig tool

A shell and drilling die technology, which is applied to the drilling die, positioning device, manufacturing tool and other directions for workpieces, can solve the problems of increased manufacturing cost, low labor efficiency, and high labor intensity of staff, so as to improve work efficiency. , the effect of saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

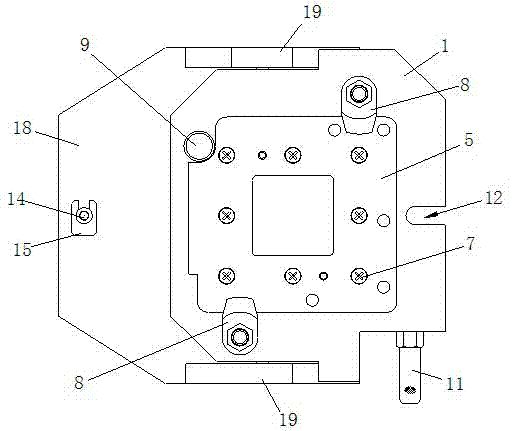

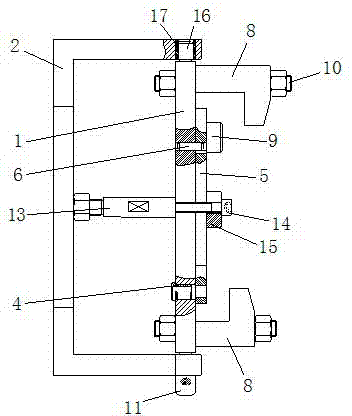

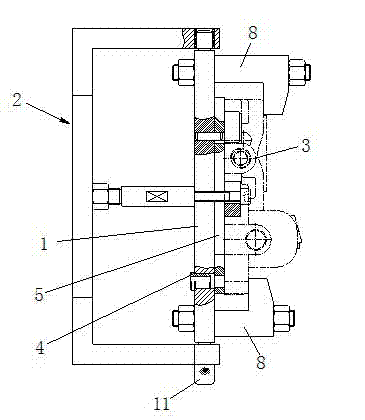

[0014] The present invention will be further explained below in conjunction with the drawings:

[0015] Such as figure 1 , figure 2 The shown tooling for a casting shell drilling mold includes a drilling template 1 for placing a workpiece. The drilling template 1 is rotatably supported on a clamping body 2. The drilling template 1 is provided with a positioning and locking device for pressing the workpiece 3 , The clamping body 2 is provided with a pressing device for fixing the drill template 1 after the drill template 1 is turned over, and a drill sleeve 4 is provided on the drill template 1.

[0016] Further, the drill template 1 is provided with a profiling backing plate 5 that matches the shape of the workpiece 3, and a first positioning pin 6 for positioning the two is provided between the drilling template 1 and the profiling backing plate 5. The first screw 7 is fixed with the drill template 1, and the workpiece 3 is placed on the profiling backing plate 5 and positioned b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com