Stereoscopic curing system and method

A maintenance system and three-dimensional technology, applied in the field of construction machinery, can solve problems such as difficulty in meeting industrialized production, unfavorable efficiency, and large space occupied by the maintenance kiln, and achieve the effect of saving space and improving maintenance efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

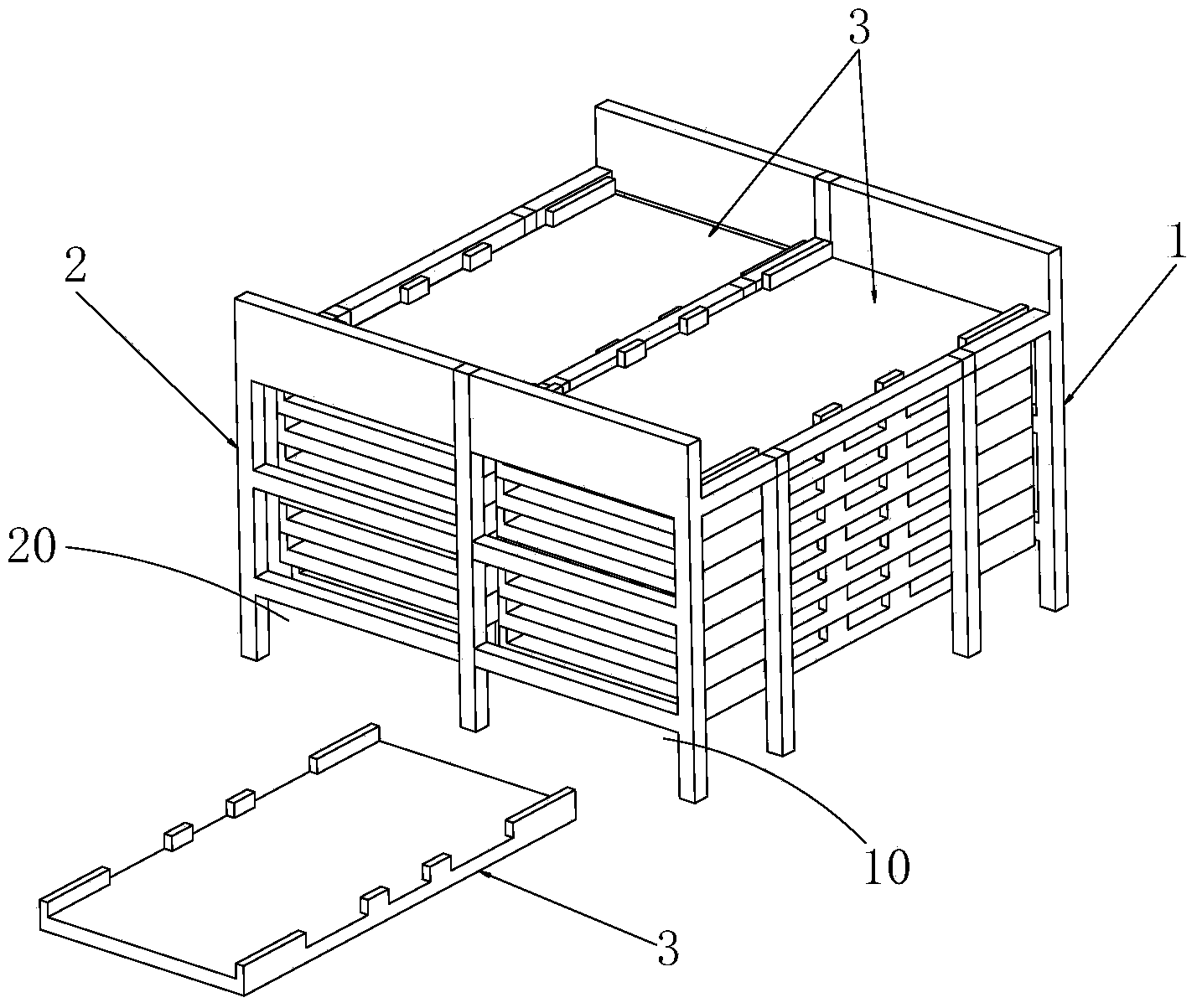

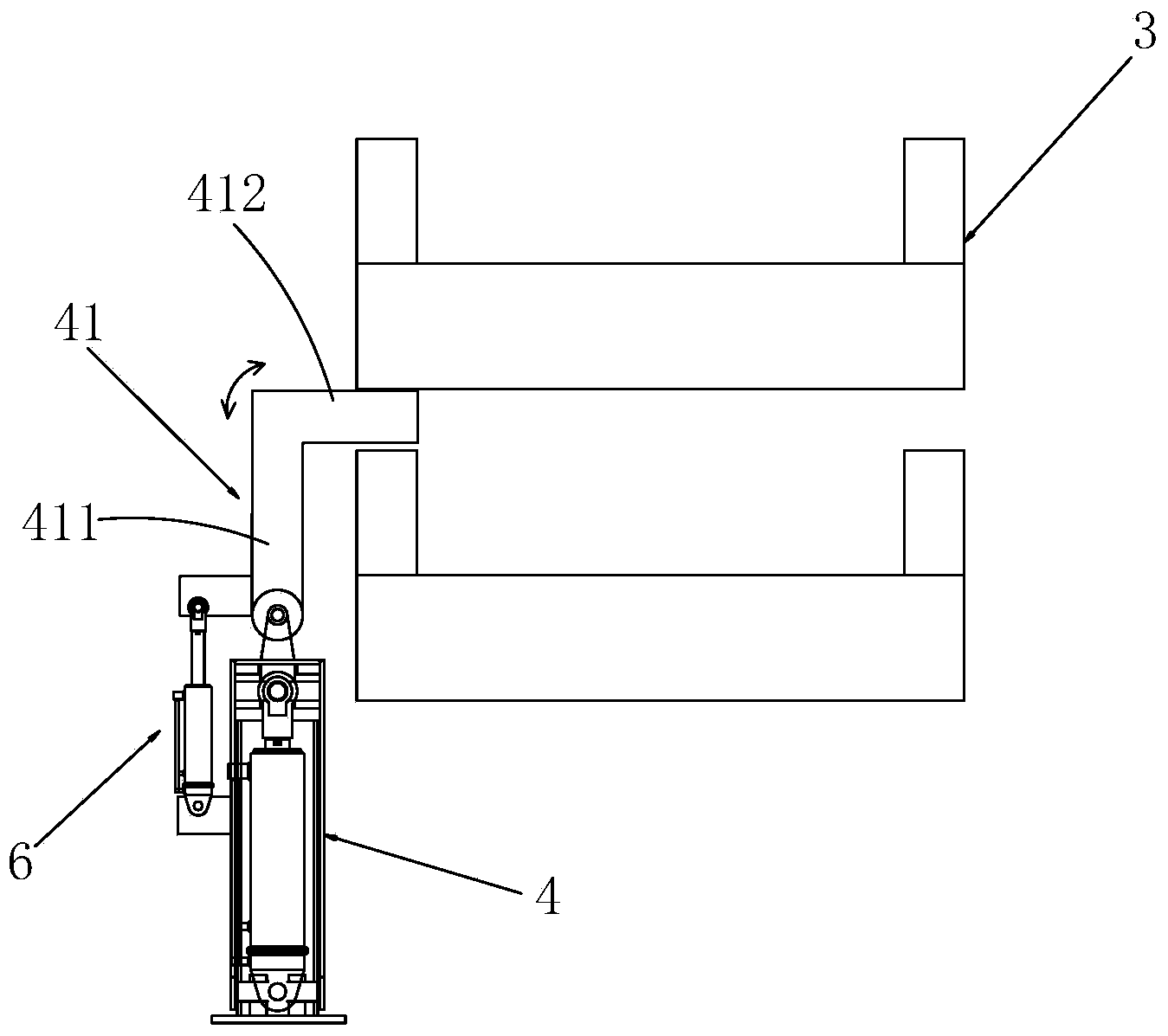

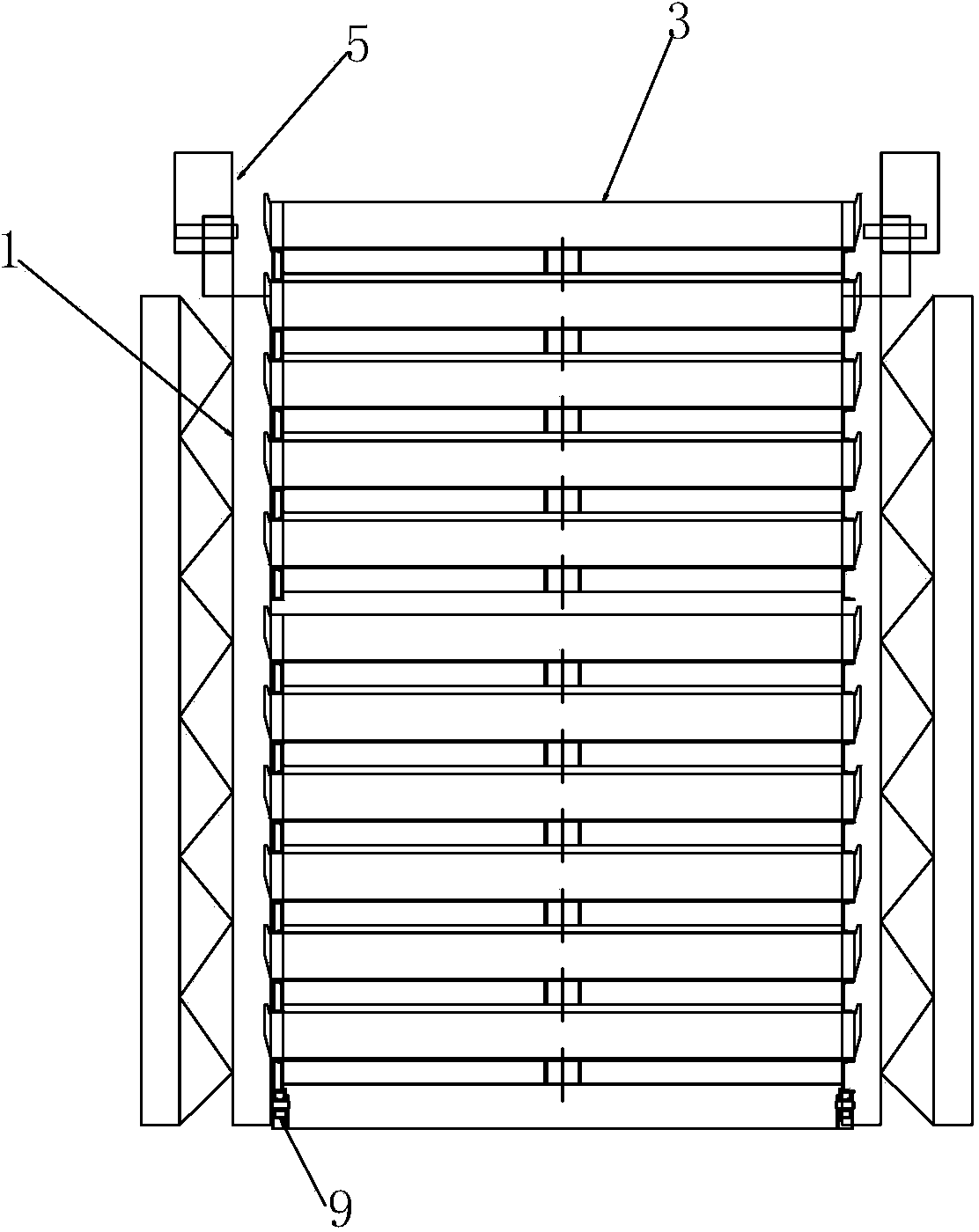

[0033] Such as Figure 1-4 As shown, the three-dimensional curing system of an embodiment of the present invention includes at least one first curing kiln 1 and at least one second curing kiln 2 arranged adjacent to each other, several curing mold bases 3 for carrying prefabricated parts to be cured, the first A lifting device 4, a horizontal conveying device 5 and a heating device (not shown); several curing mold bases 3 can enter and exit the first curing kiln 1 and the second curing kiln 2, so as to send the preforms to be cured into and out The first curing kiln 1 and the second curing kiln 2; the first lifting device 4 is arranged at the bottom of the first curing kiln 1, and is used to drive the curing mold base 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com