Polyvinyl chloride floor based on sectional material framework constraint

A technology of stone-plastic flooring and profiles, applied in floors, buildings, building structures, etc., can solve the problems of easy opening, stone-plastic flooring is too soft, etc., to achieve difficult opening, avoid rework and energy waste, and heat resistance The effect of expansion and contraction improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

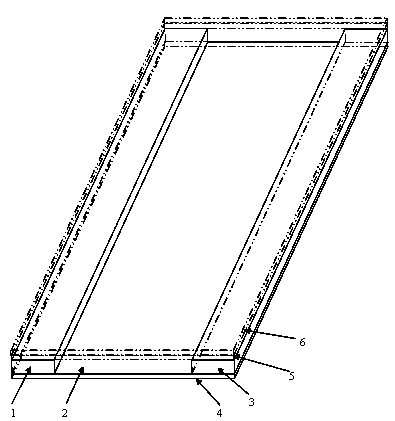

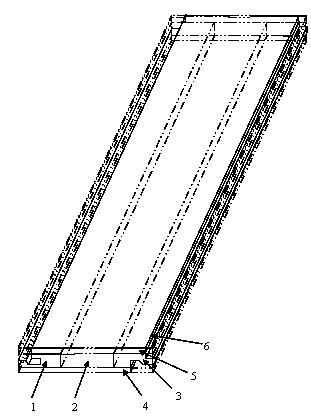

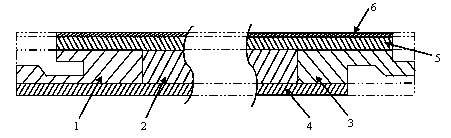

[0027] Such as figure 1 As shown, a stone-plastic floor constrained by profile skeleton of the present invention is composed of stone-plastic floor units assembled. Each stone-plastic floor unit includes a first profile 1 , a stone-plastic sheet 2 , a second profile 3 , a back sheet 4 and an upper sheet 5 . The first profile 1 , the stone-plastic sheet 2 and the second profile 3 are located between the bottom sheet 4 and the top sheet 5 . The first profile 1 , the stone-plastic sheet 2 and the second profile 3 are arranged transversely, and the stone-plastic sheet 2 is embedded between the first profile 1 and the second profile 3 . Each stone-plastic floor unit is connected as a whole through plasticized lamination. Both sides of each stone-plastic floor unit are grooved. Adjacent stone-plastic floor units are joined together through notc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com