Space Optical Remote Sensor Vacuum Thermal Test Extraterrestrial Heat Flow Simulator

A technology for space optical remote sensing and vacuum thermal testing, which is applied in the field of ground testing of space optical remote sensors, can solve the problem that the thermal balance test of optical remote sensor and the thermo-optical test cannot be carried out synchronously, meet the needs of optical detection, save resources, The effect of low heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

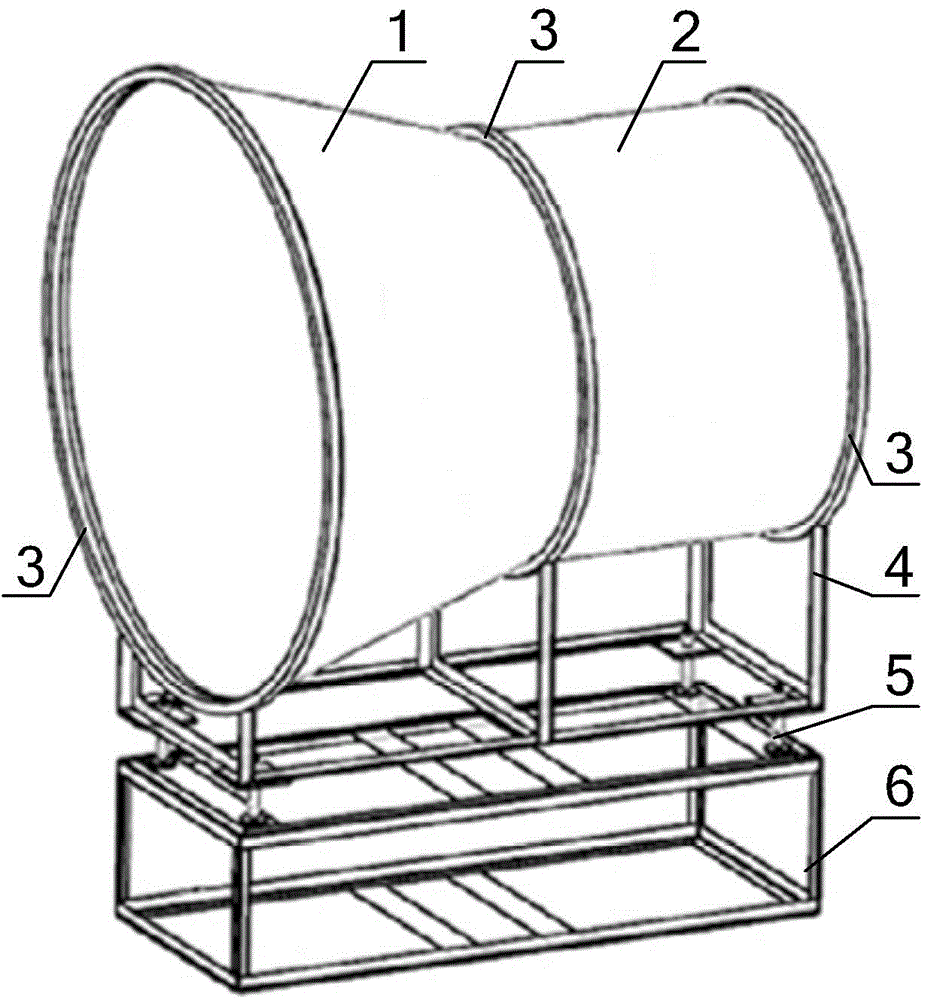

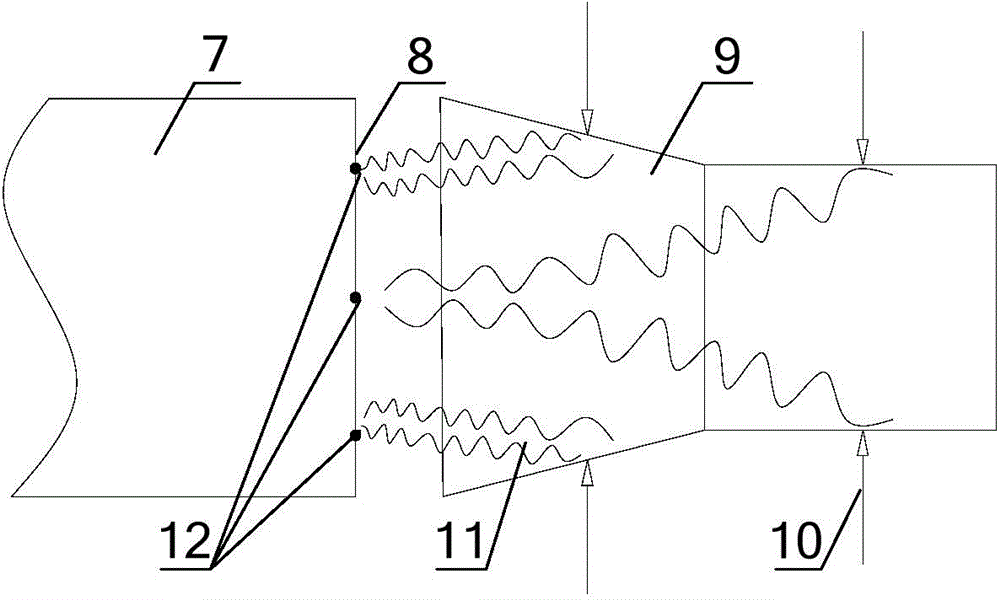

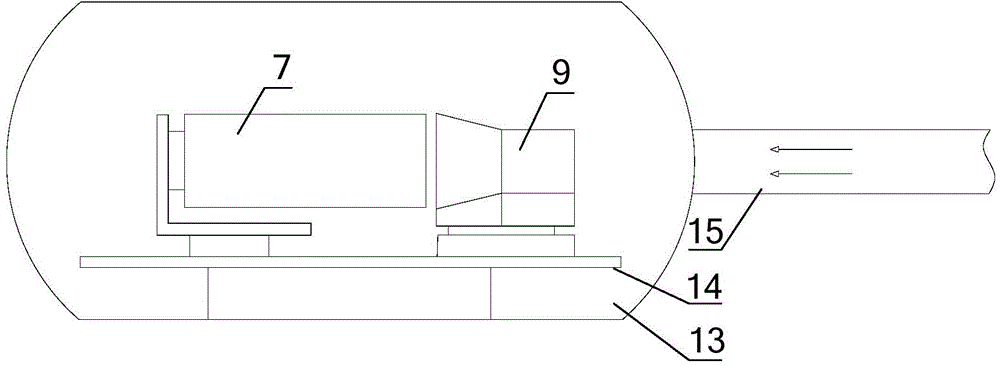

[0018] See attached figure 1 , the extraterrestrial heat flow simulator for space optical remote sensor vacuum heat test of the present invention includes a cylinder and a bracket, the cylinder is a trumpet-shaped hollow structure, the material of the cylinder is a 2mm thick aluminum alloy plate, and the inner surface of the cylinder is sprayed to emit The emissivity of the black paint is equal to the emissivity of the inner surface of the heat sink of the space environment simulator 13. The front end 1 of the cylinder and the rear end 2 of the cylinder are respectively divided into four heating zones, and the cylinder is heated in zones , if it is necessary to improve the simulation accuracy of the external heat flow, the heating area can be further subdivided. The electric heater can use dual heating circuit heaters as needed. When the main and backup ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com